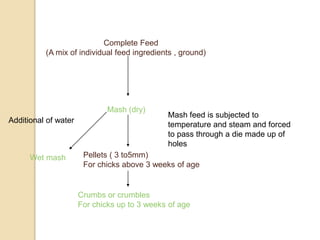

This document discusses feeding management for poultry. It covers various forms of feed including mash, pellets and crumbles. It also discusses feeding programs, economizing feed costs, reducing waste, and storage. Specific topics covered include feeding chicks, pullets, layers, broilers and breeders. Advantages and disadvantages of different feed forms are provided.