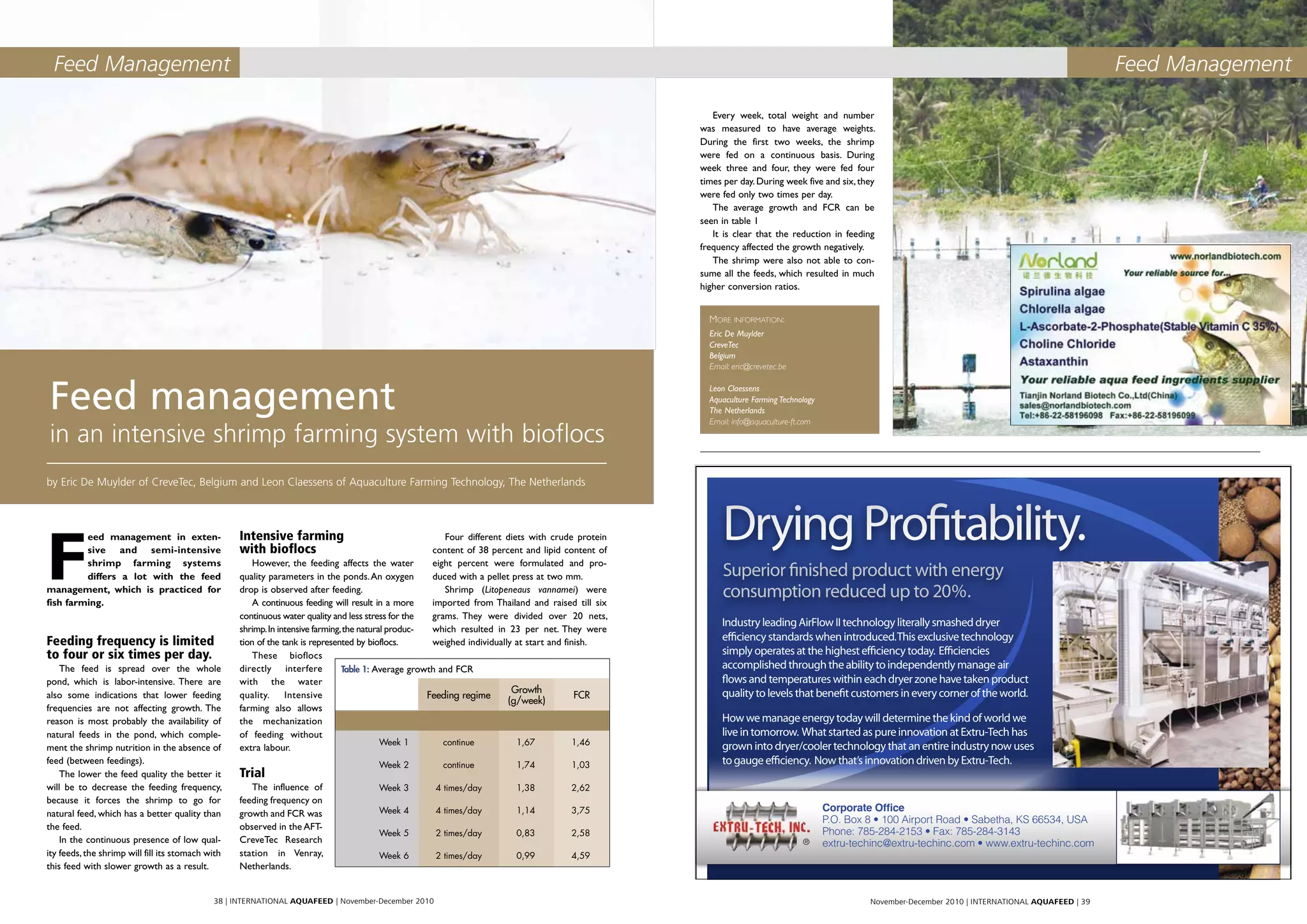

The document discusses feed management strategies in shrimp farming, emphasizing the differences between intensive and extensive systems. It highlights a trial conducted that revealed lower feeding frequencies adversely affected growth rates and feed conversion ratios in shrimp. Additionally, it addresses the advancements in aquaculture netting systems that enhance environmental sustainability and profitability in fish farming.