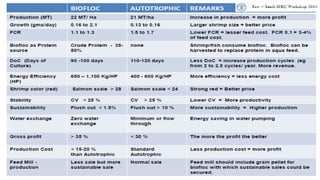

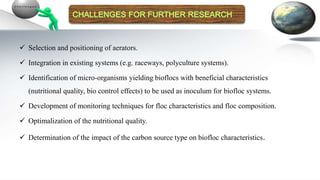

This document summarizes a presentation on biofloc technology given by Mr. Tarang Kumar Shah for his PhD in Aquaculture. It discusses how biofloc technology works by balancing carbon and nitrogen to form protein-rich flocs that maintain water quality. It also outlines the history and mechanisms of biofloc formation, factors influencing flocs, and applications of biofloc technology in aquaculture including shrimp and fish farming, nursery and grow-out phases, and its potential benefits for aquaponics and breeding.