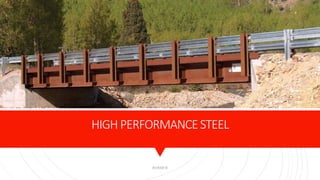

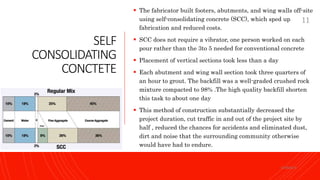

The document discusses innovative technologies in bridge construction that enhance efficiency, reduce costs, and improve durability, focusing on fast track construction methods. Key advancements include the use of high-performance and self-consolidating concrete, prefabricated components, and high-speed welding technology, all aimed at minimizing traffic disruption and construction time. The implementation of these technologies not only yields faster project completion but also results in safer and more resilient structures.