This document provides a case study on lessons learned from Boeing's 787 Dreamliner project. Key points:

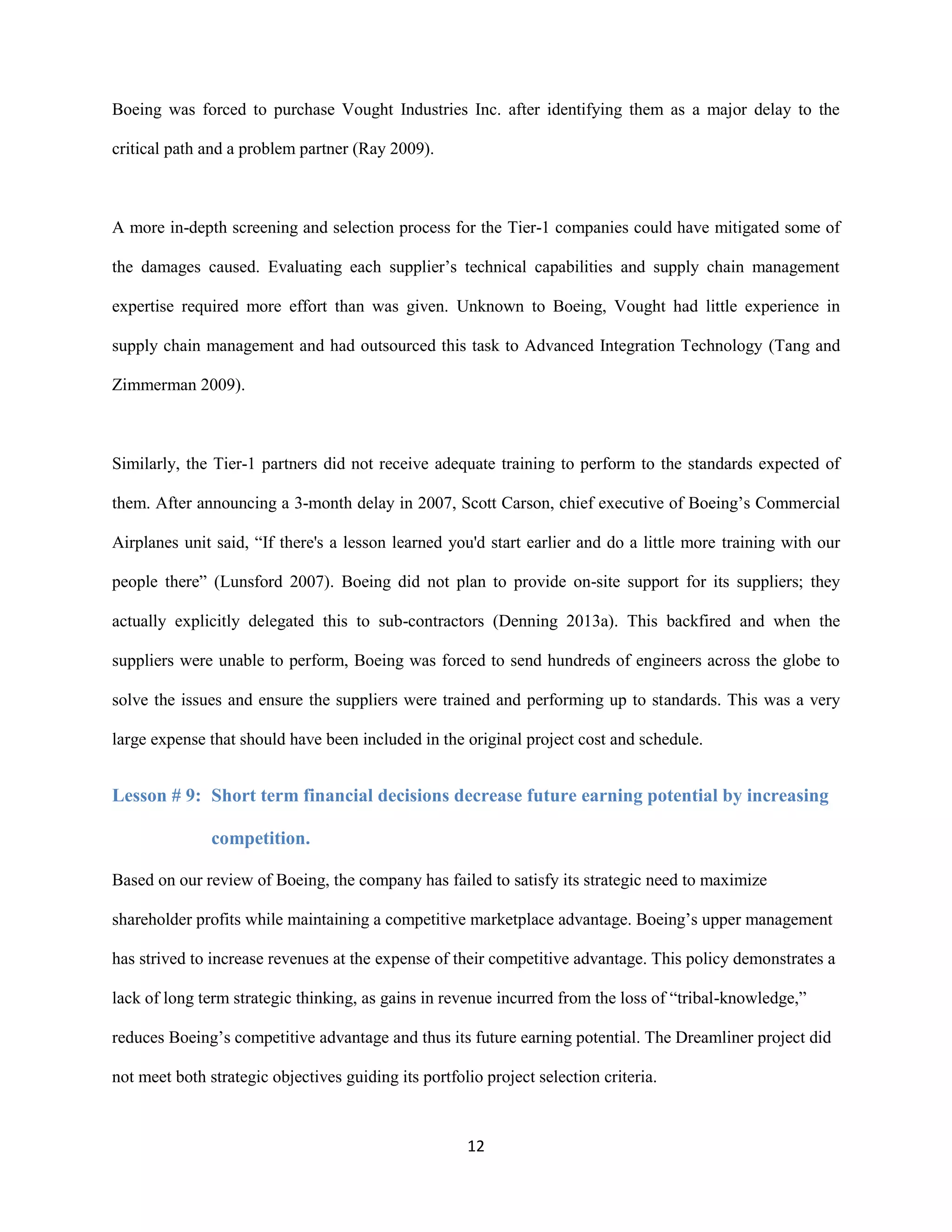

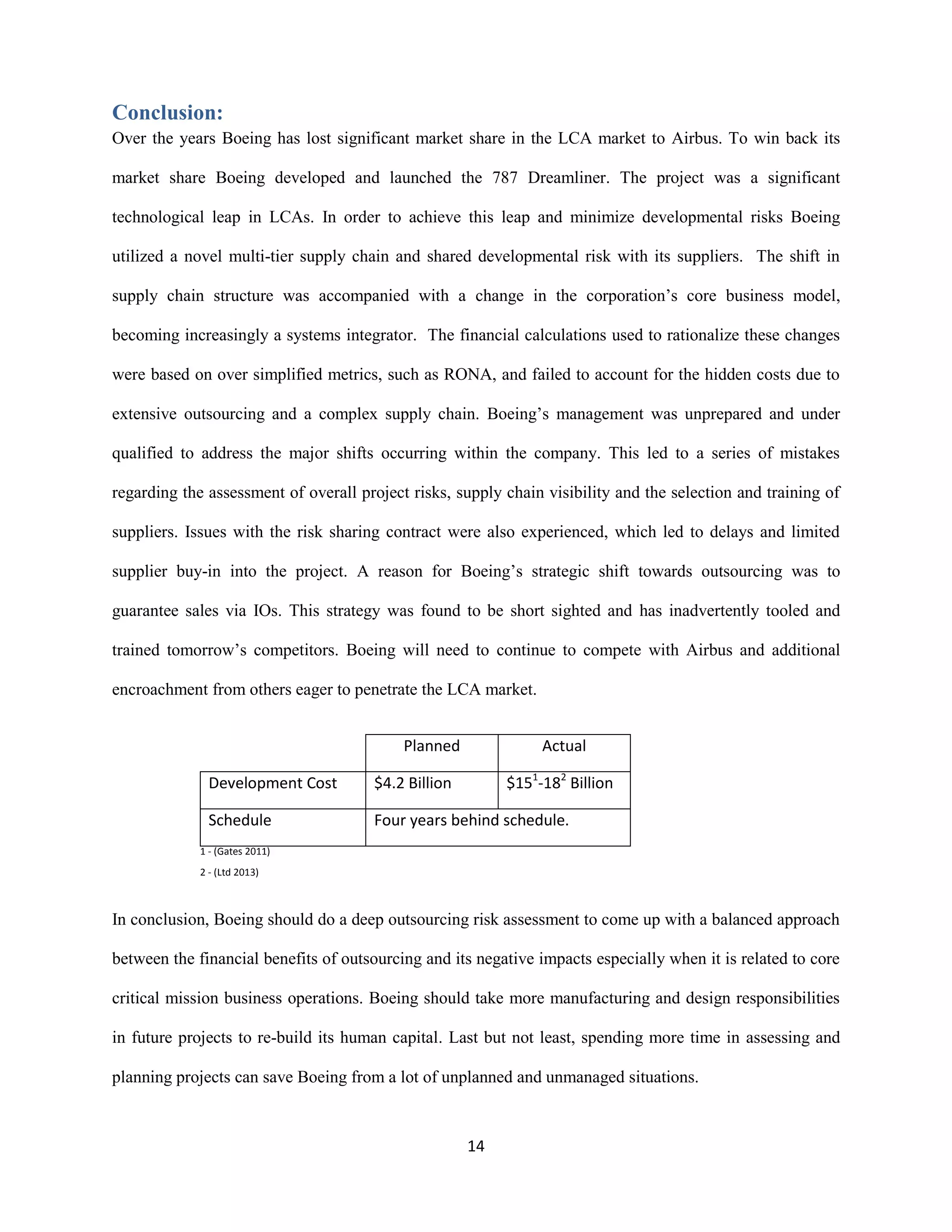

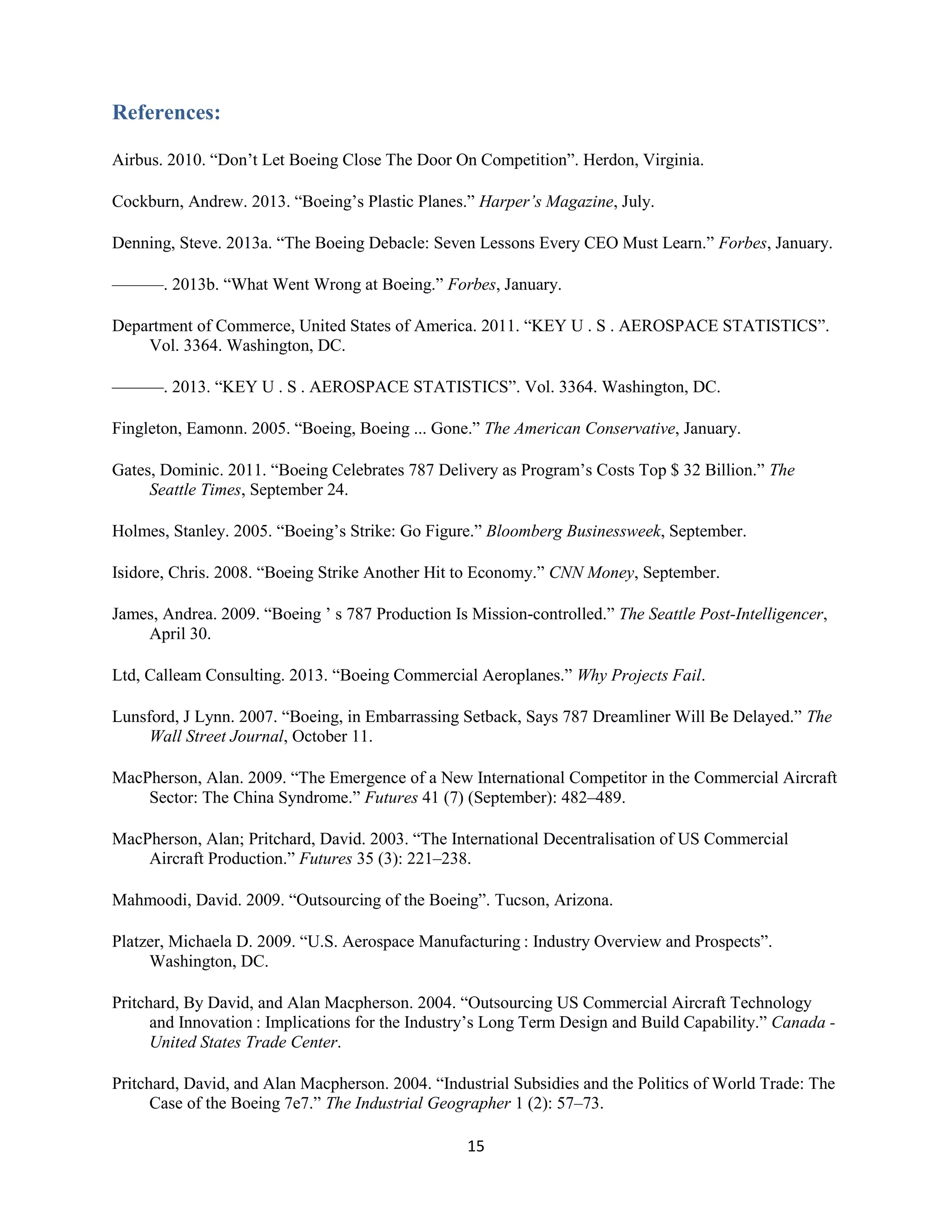

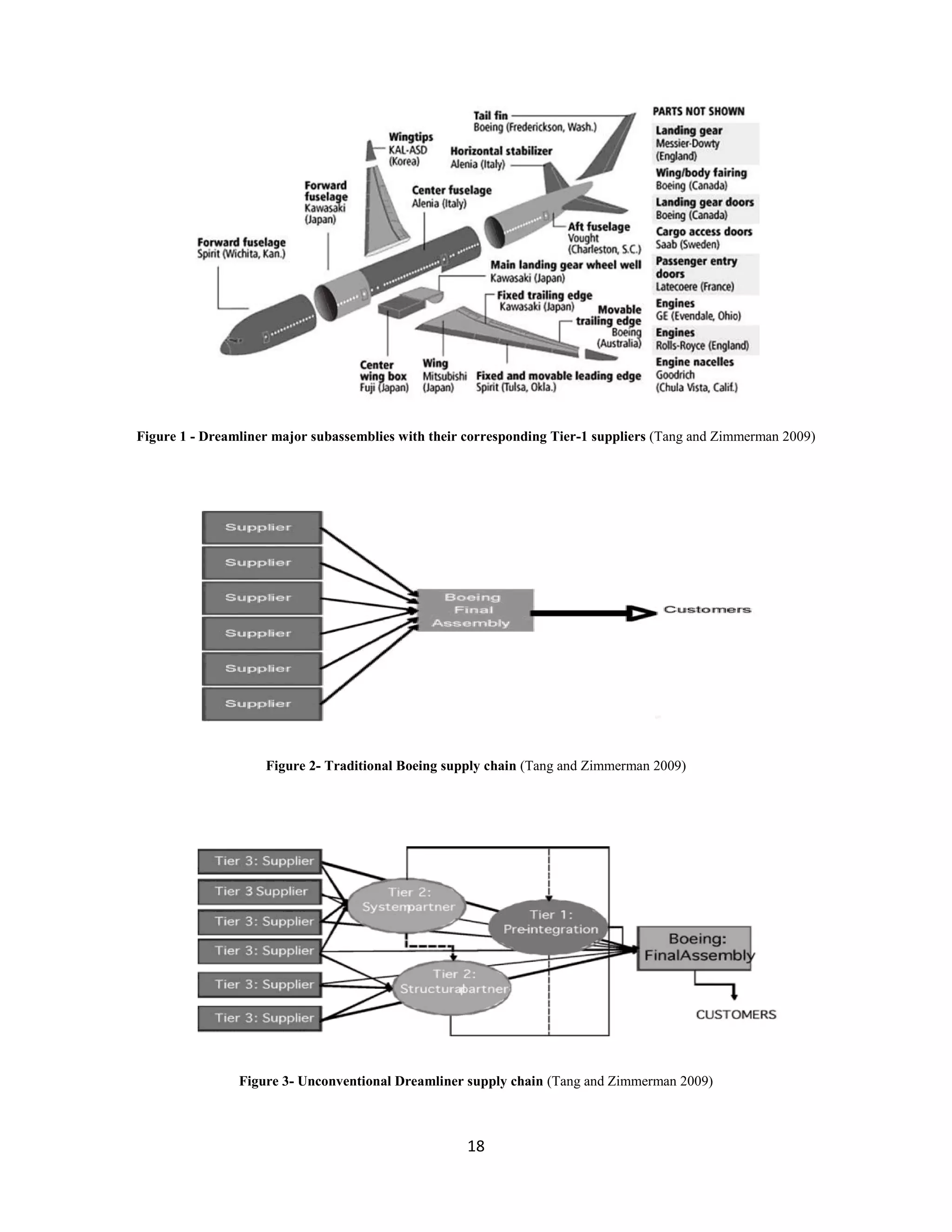

- Boeing significantly increased outsourcing for the 787 to 70% in an attempt to reduce costs and risks, utilizing a novel multi-tier supply chain model. This led to underestimating integration costs and losing control over key technologies.

- Major delays occurred, with the first 787 delivery over 2 years late. Issues with lithium batteries also grounded the 787 fleet temporarily in 2013.

- Nine lessons are identified, including the need for accurate cost estimation considering all costs, assembling a management team with supply chain expertise, and proactively managing labor union relationships. Outsourcing too