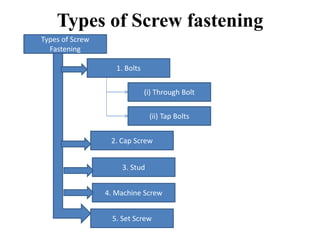

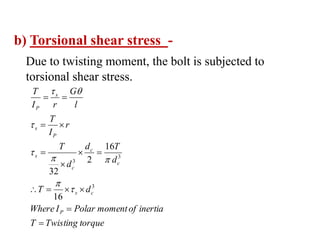

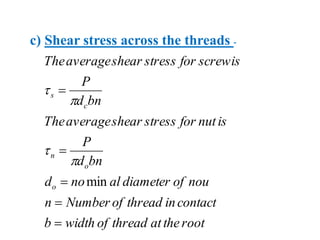

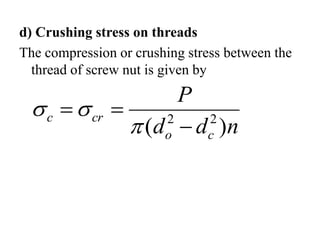

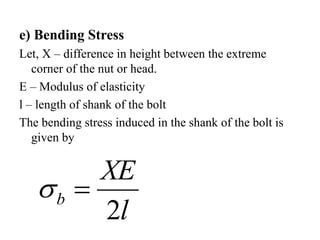

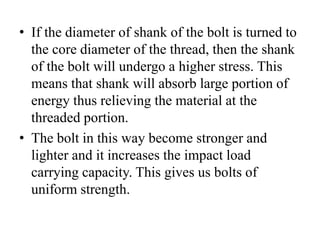

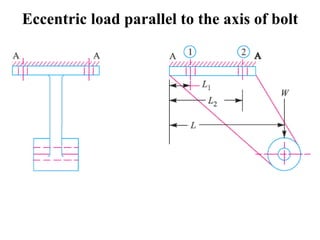

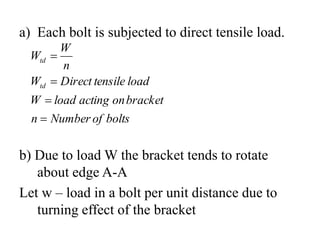

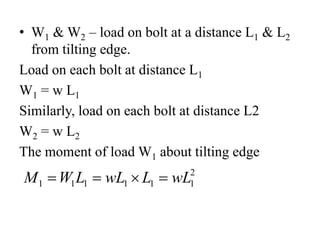

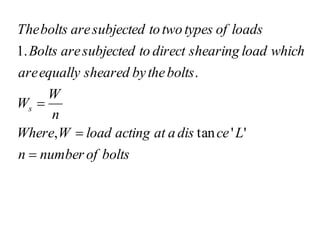

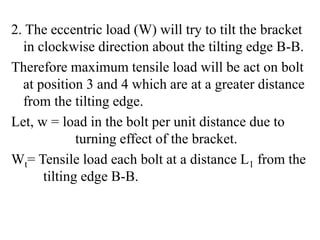

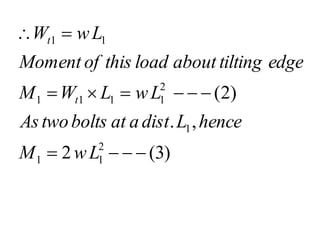

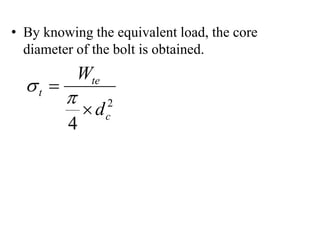

The document discusses the design of various types of screw fasteners. It describes screw threads as helical grooves cut into cylindrical surfaces. Screw joints are commonly used for assembly and have advantages of being convenient to assemble/disassemble, reliable, and inexpensive due to standardization. The main types of screw fasteners are bolts, screws, studs, tapping screws, and set screws. Stresses in screw joints include tension, torsional shear, shear across threads, crushing stress, and bending stress. Screw joints are also subjected to stresses from initial tightening and external loads. Design considerations are discussed for bolted joints under eccentric loading parallel or perpendicular to the bolt axis.

![b) Shear Stress in bolt –

n

d

P

o

s

2

4

c) Combine tension and shear stress

]

4

[

2

1

]

4

[

2

1

)

(

2

2

max

2

2

max

t

t

t

t

stress

shear

Maximum

sress

tensile

principal

Maximum](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-25-320.jpg)

![• Similarly, the moment of load W2 about tilting

edge

)

2

(

,

tan

)

1

(

]

[

2 2

2

2

1

2

1

2

2

2

2

2

2

2

WL

M

edge

tilting

about

L

ce

dis

a

at

W

load

the

of

moment

The

wL

wL

M

M

M

edge

tilting

about

load

of

moment

Total

wL

L

wL

L

W

M

Equating equation (1) and (2)](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-36-320.jpg)

![2

2

2

2

2

1

2

2

2

2

2

2

2

2

2

1

2

2

2

1

2

2

2

1

4

]

[

2

tan

tan

]

[

2

]

[

2

]

[

2

c

t

t

t

td

t

Total

t

d

W

stress

tensile

to

subjected

bolt

the

As

W

W

W

W

bolts

loaded

heavily

most

on

load

Total

L

L

L

L

W

wL

W

W

L

ce

dis

at

bolt

each

on

load

Tensile

loaded

heavily

most

are

L

ce

dis

at

bolts

The

L

L

WL

w

L

L

w

wL

wL

WL

](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-37-320.jpg)

![• Similarly Wt will be the tensile load each bolt at

a distance L2 from the tilting edge B-B.

)

5

(

]

[

2

2

2

)

4

(

2

,

.

2

2

2

1

2

2

2

1

2

1

2

2

2

2

2

2

2

2

2

2

2

2

L

L

w

M

L

w

L

w

M

M

M

M

is

edge

tilting

about

moment

Total

L

w

M

hence

L

dist

a

at

are

bolts

two

the

As

L

w

L

W

M

edge

tilting

about

W

load

the

of

Moment

L

w

W

t

t

t](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-42-320.jpg)

![)

7

(

]

[

2

]

[

2

.

.

4

&

3

max

]

[

2

]

[

2

6

&

5

)

6

(

.

)

(

2

2

2

1

2

2

2

2

2

2

1

2

2

2

2

2

2

1

2

2

2

1

L

L

L

L

W

W

L

L

L

L

W

L

w

W

edge

tilting

from

L

dist

a

at

situated

are

which

bolt

a

in

willbe

load

tensile

imum

The

L

L

L

W

w

L

L

w

L

W

equation

Equating

L

W

M

is

L

dist

a

at

W

load

to

due

bracket

of

moment

The

t

t](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-43-320.jpg)

![]

4

[

2

1

)

(

]

4

[

2

1

)

(

.

2

2

2

2

2

2

2

s

t

se

se

s

t

t

te

te

W

W

W

W

load

shear

Equivalent

And

W

W

W

W

W

load

tensile

Equivalent

load

shear

as

well

as

tensile

combile

to

subjected

are

bolts

the

As

](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-44-320.jpg)

![• Sum of turning moment due to eccentric load and

internal resisting moment of the bolt must be

zero.

calculated

is

W

b

equation

From

b

l

l

l

l

l

W

l

l

l

W

l

l

l

W

l

l

l

W

l

W

l

W

l

W

l

W

l

W

e

W

1

2

4

2

3

2

2

2

1

1

1

4

1

4

1

3

1

3

1

2

1

2

1

1

1

4

4

3

3

2

2

1

1

'

'

)

(

]

[

)

(

)

(

)

(

](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-50-320.jpg)

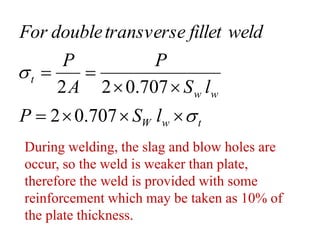

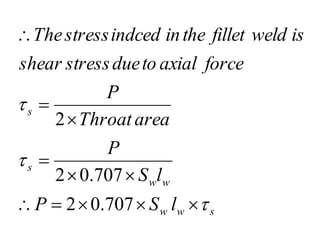

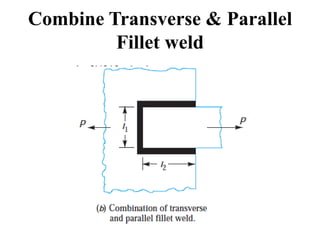

![• In combination of parallel and transverse fillet

weld, the weld is subjected to tensile stress and

shear stress due to axial force.

]

707

.

0

2

[

]

707

.

0

[

)

2

(

707

.

0

2

)

1

(

707

.

0

2

1

2

1

s

w

w

t

w

w

t

s

w

w

t

w

w

l

S

l

S

P

is

weld

of

strength

Total

l

S

P

weld

fillet

parallel

For

l

S

P

weld

fillet

transverse

For

](https://image.slidesharecdn.com/designoffasteners-240209122046-024c01b8/85/Design-of-Fasteners-pdf-72-320.jpg)