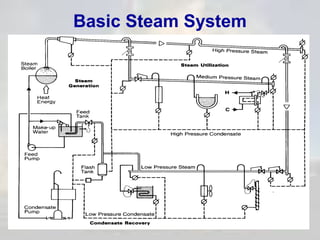

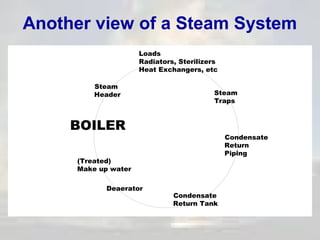

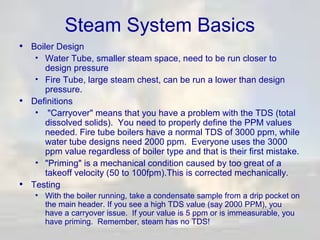

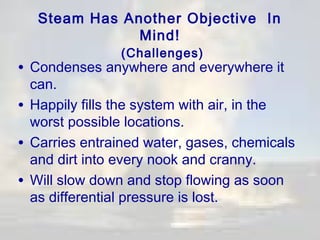

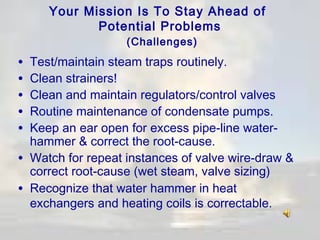

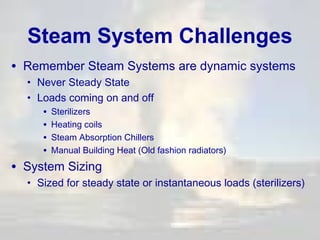

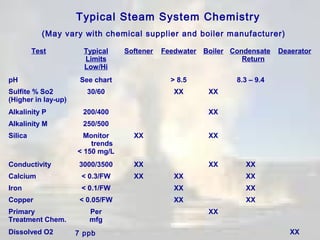

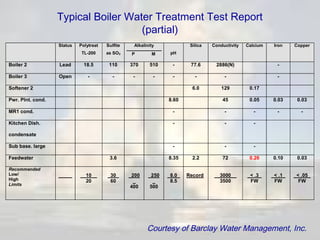

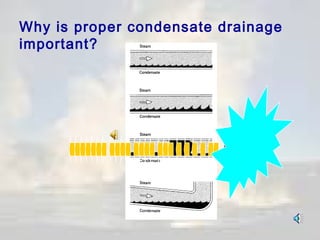

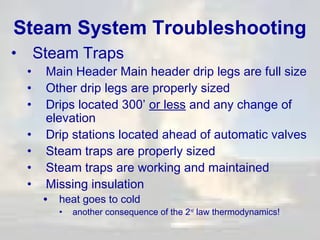

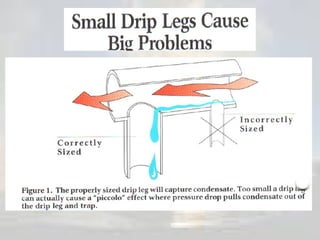

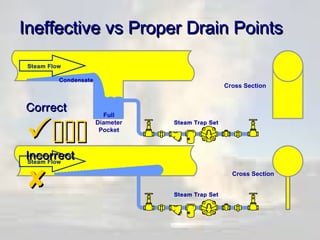

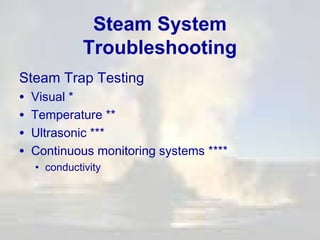

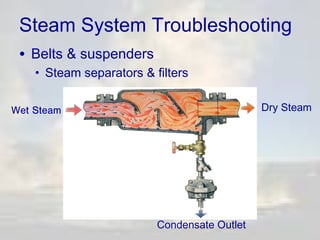

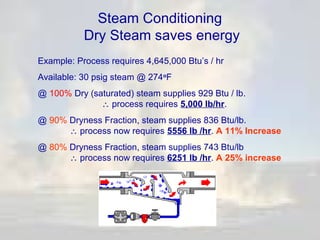

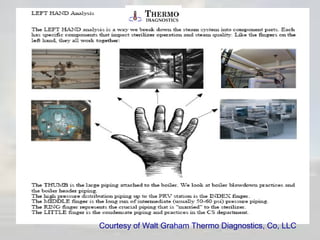

This document discusses steam systems, including challenges, troubleshooting, and basics. It covers topics such as chaos theory, the second law of thermodynamics, steam system components, common myths, chemistry requirements, water treatment testing, water level control, steam flow metering, condensate drainage importance, steam trap testing methods, steam conditioning to improve dryness, and varying system loads. Troubleshooting tips include checking for changes, following left-hand analysis from the boiler out, and addressing issues like trap repairs, water treatment modifications, and insulation repairs. Questions are welcomed.