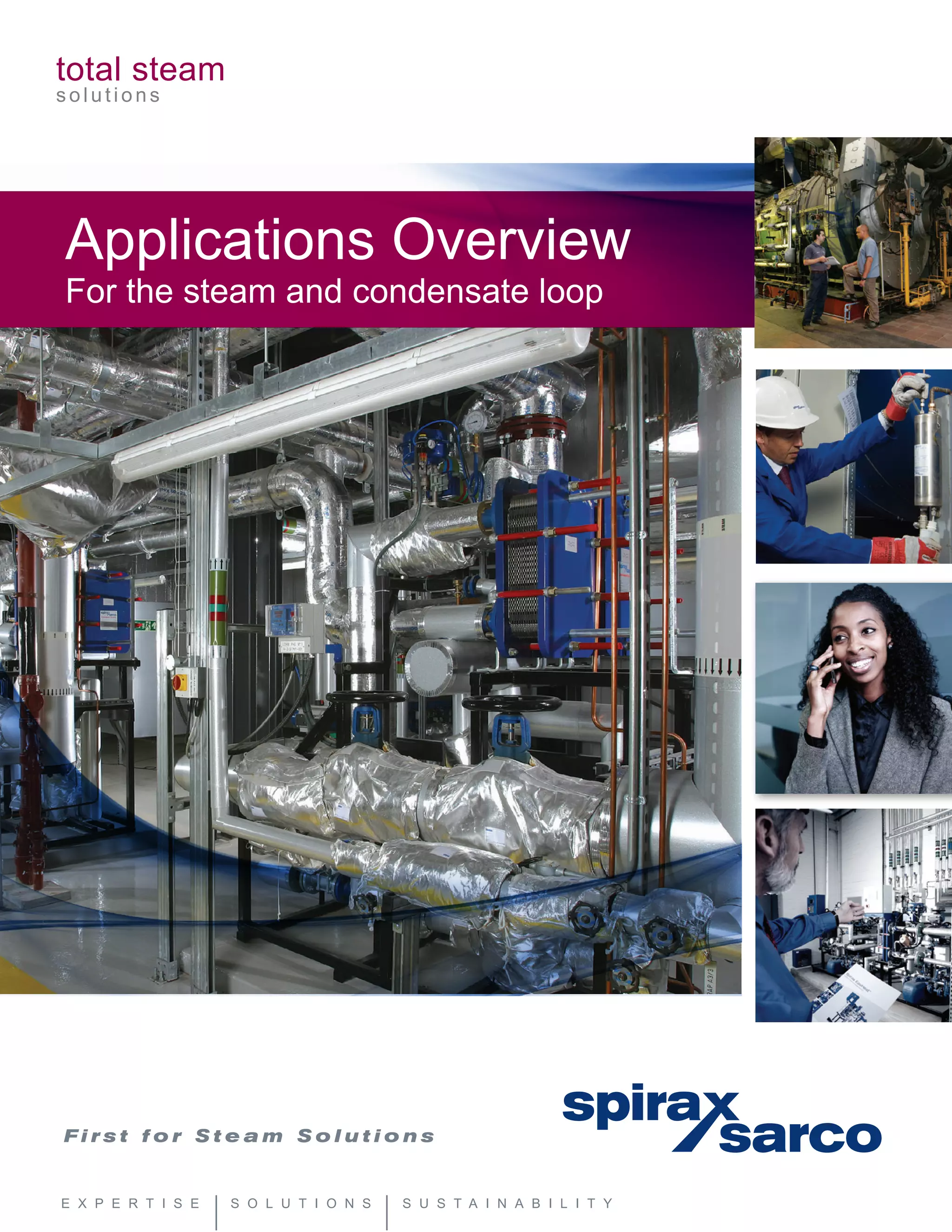

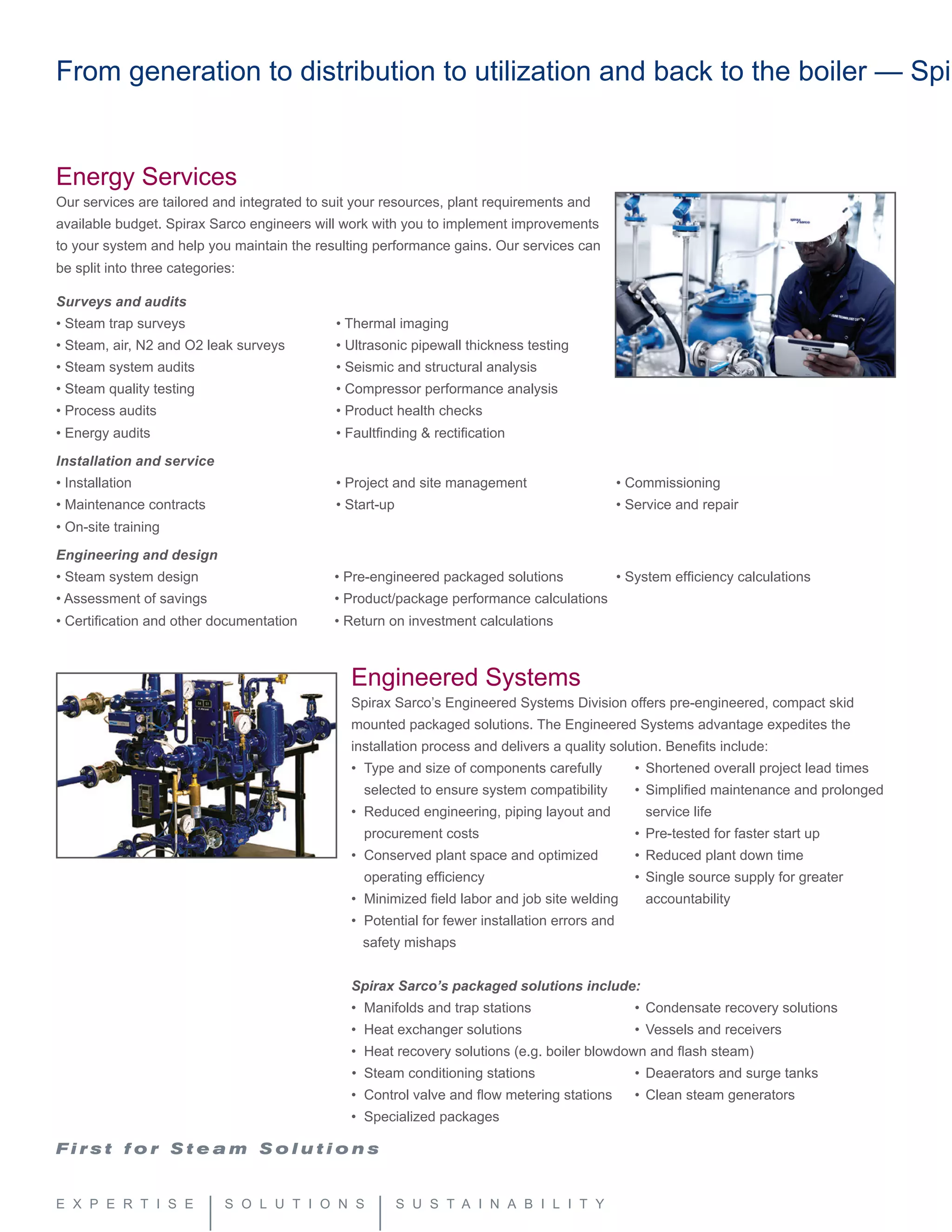

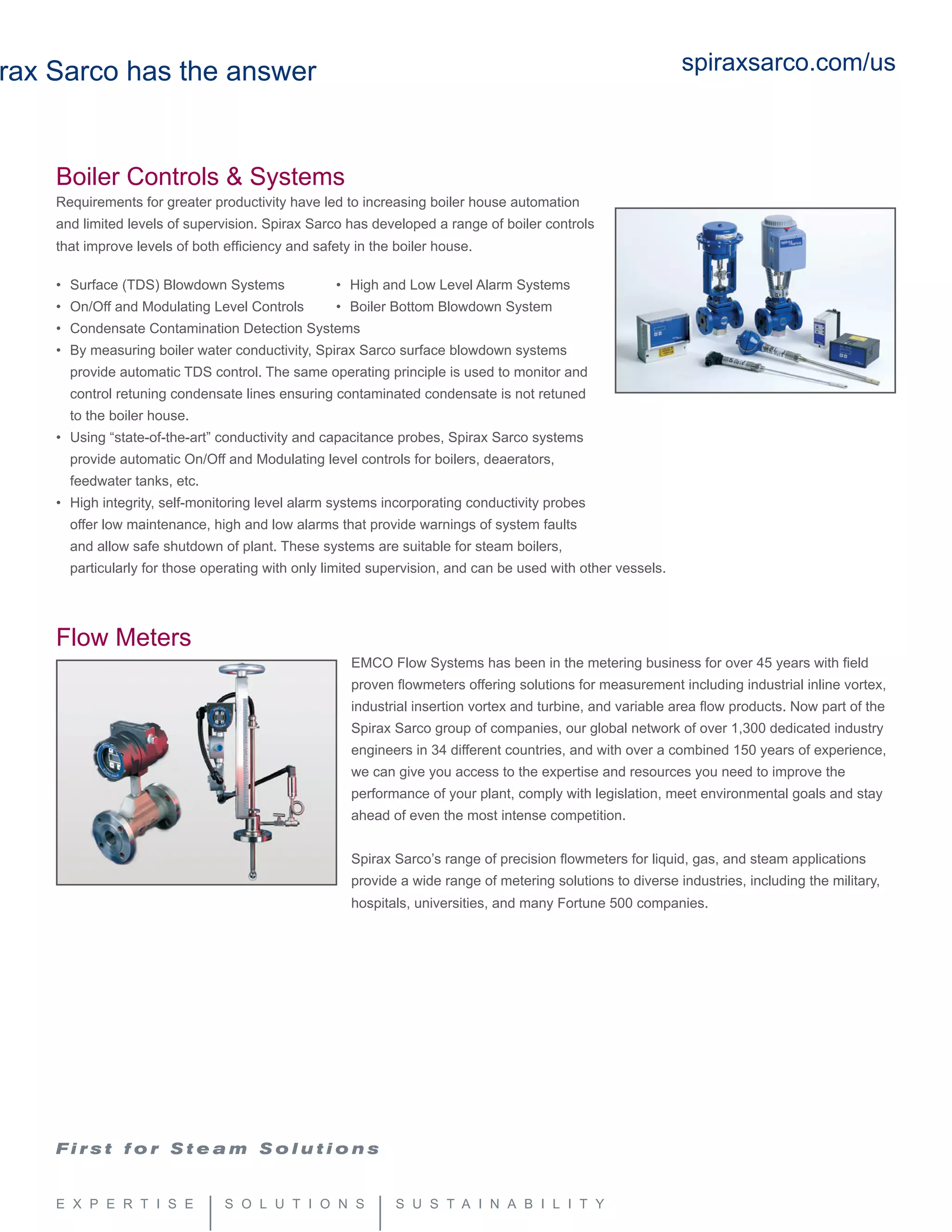

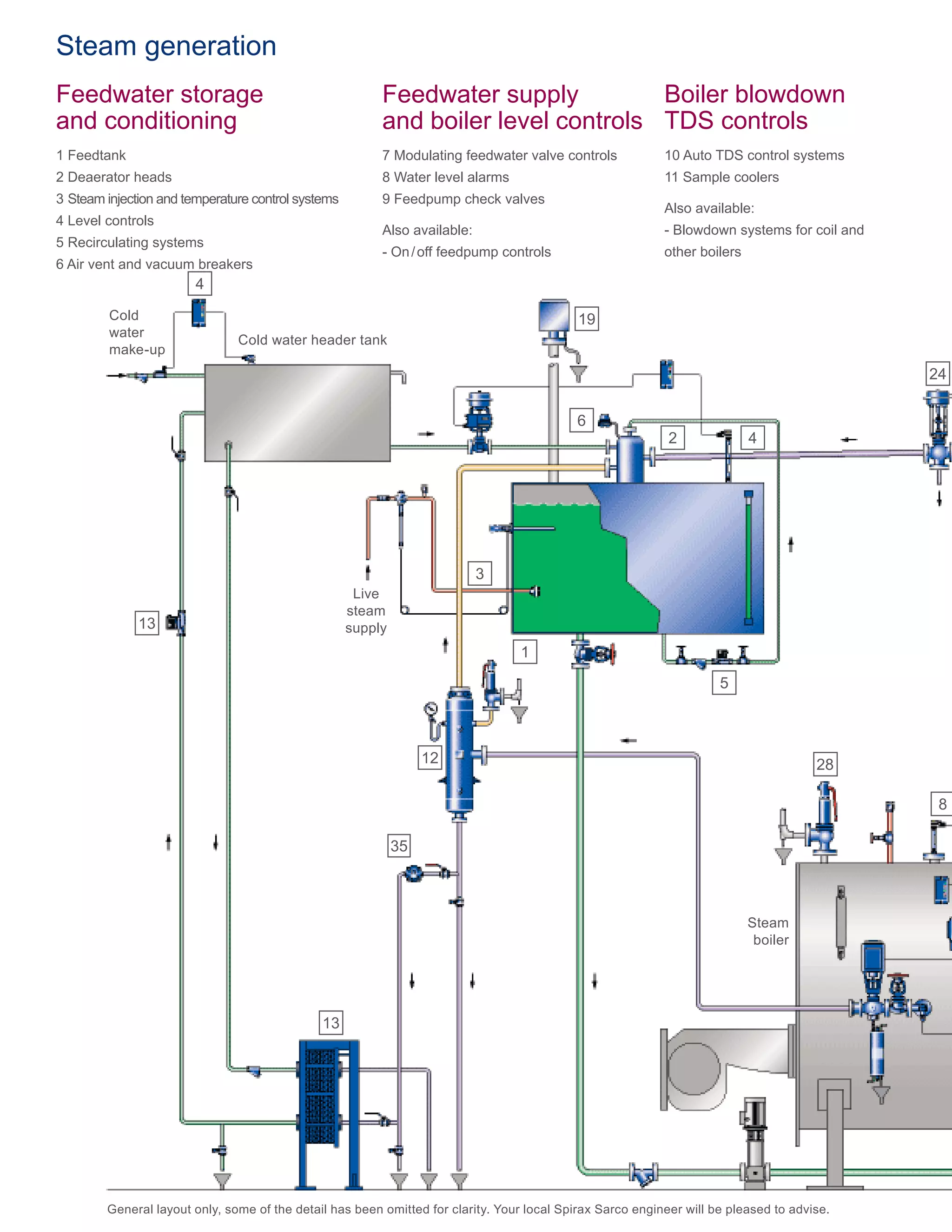

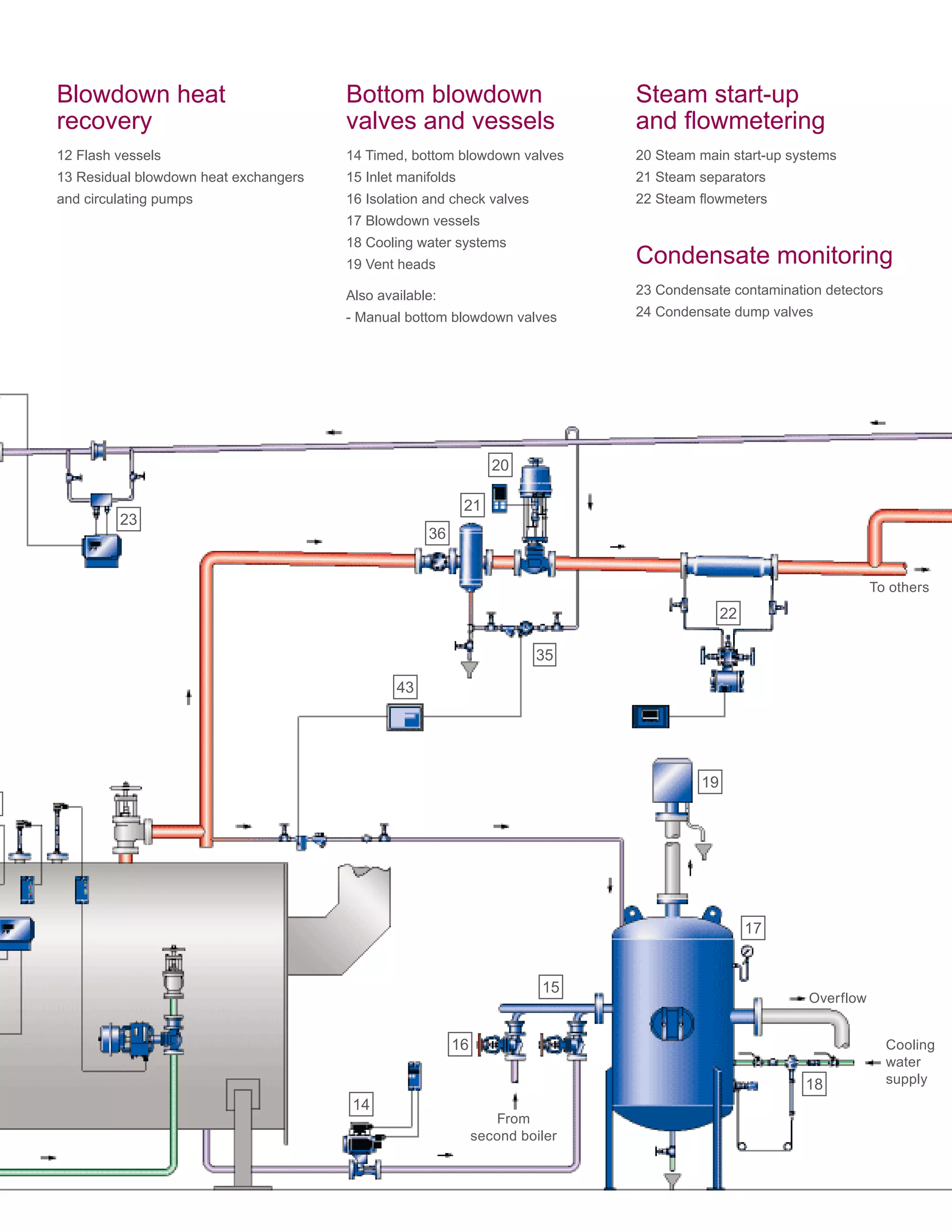

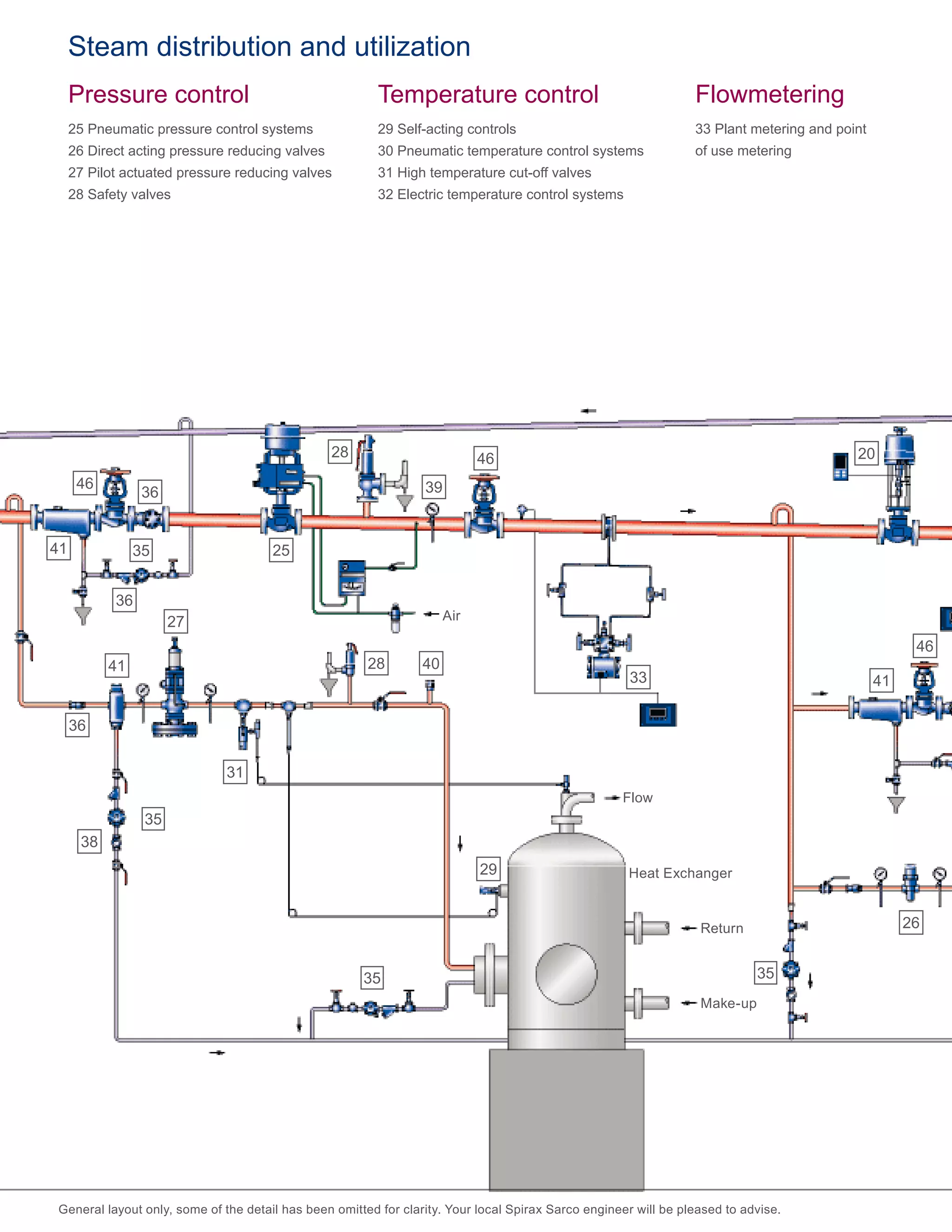

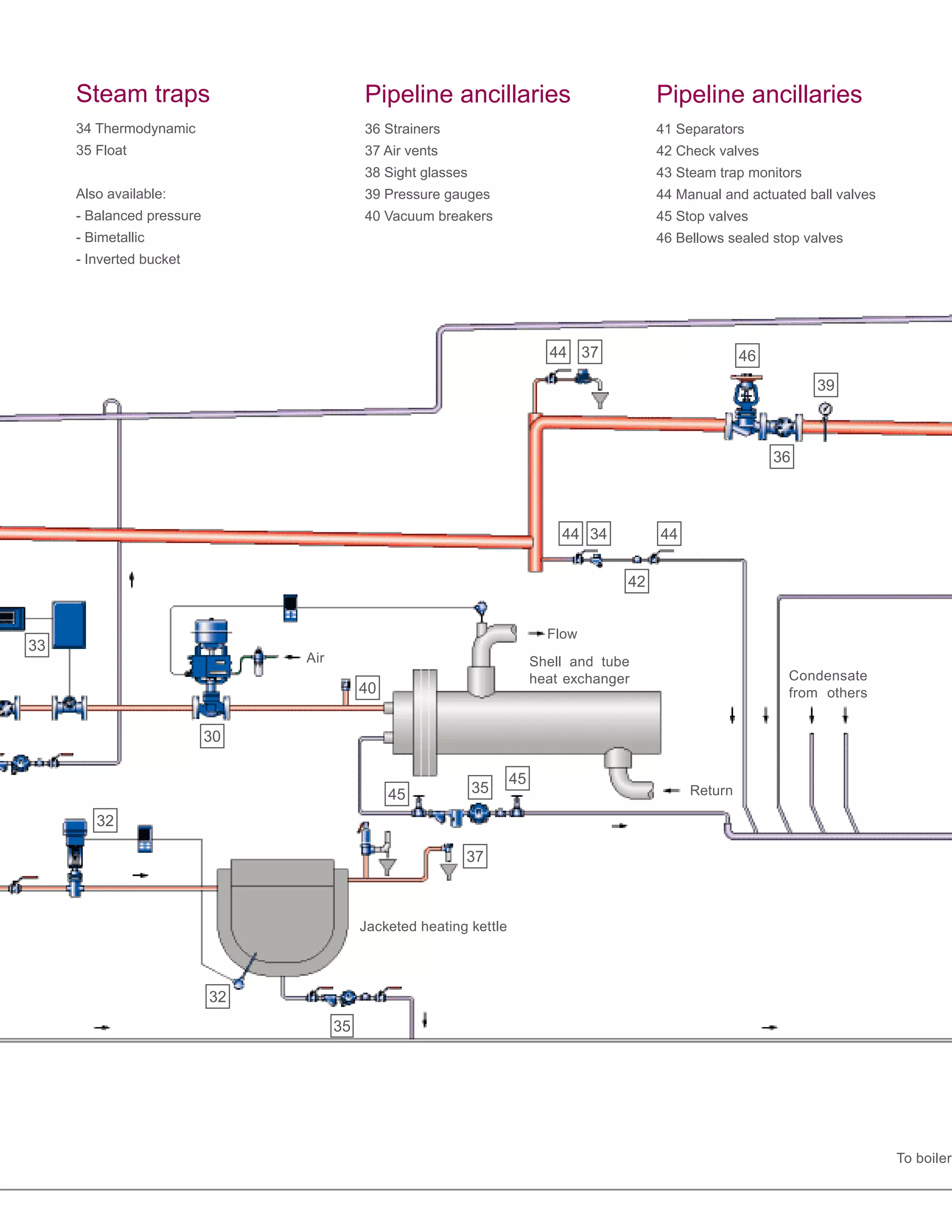

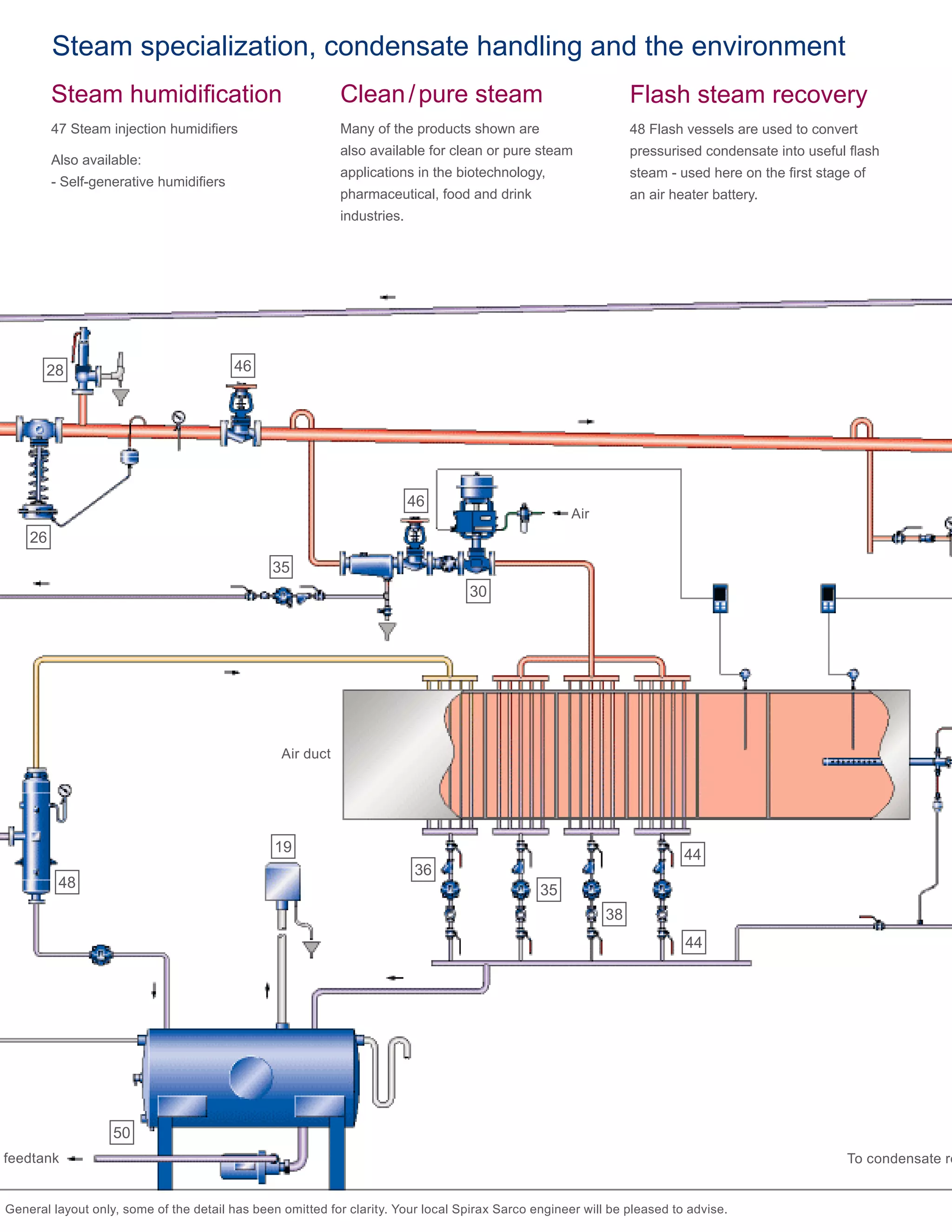

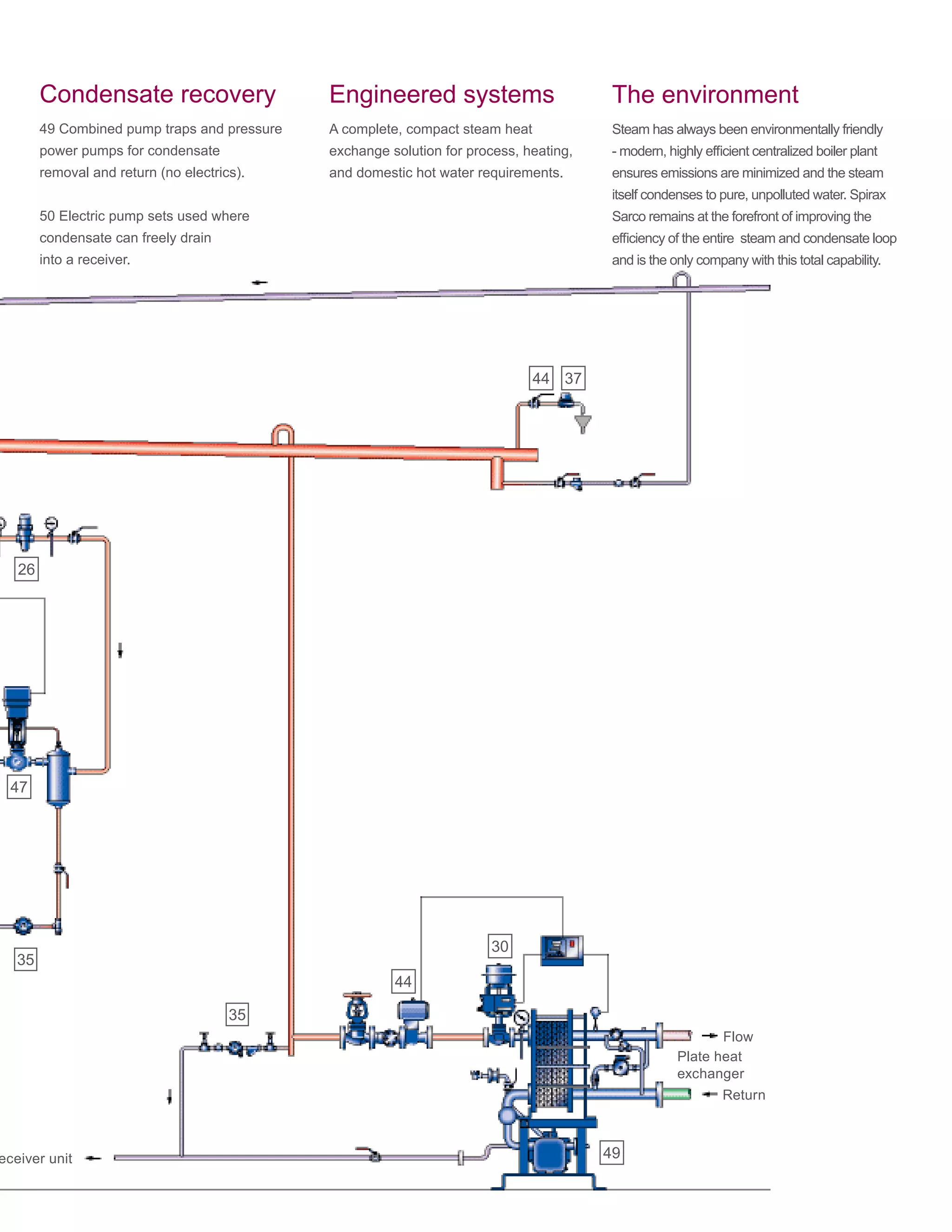

Spirax Sarco provides steam system solutions and services including surveys, audits, installation, engineering, packaged solutions, controls, steam traps, condensate pumps, high purity products, pipeline ancillaries, and training. Their services help improve steam system efficiency, productivity, and safety through solutions tailored to customer needs and budgets.