Embed presentation

Downloaded 49 times

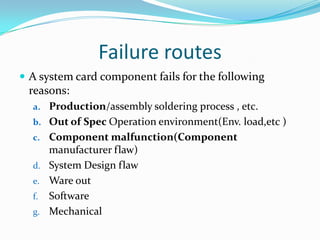

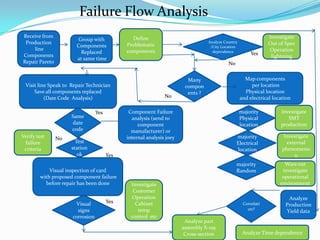

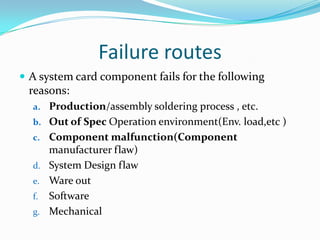

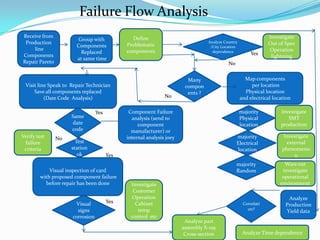

This document defines failure and outlines a failure analysis process. It defines failure as the inability of a system or component to perform its required functions under stated conditions for a specified period of time. It then lists potential causes of failure such as production issues, out of specification operating environments, component flaws, design flaws, wear out, software issues, and mechanical issues. Finally, it outlines a failure analysis process that involves receiving components from the production line, performing visual inspections, analyzing date codes, mapping component locations, and investigating various potential root causes through testing, data analysis, and component inspections.