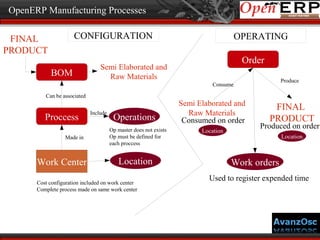

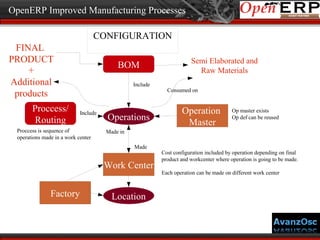

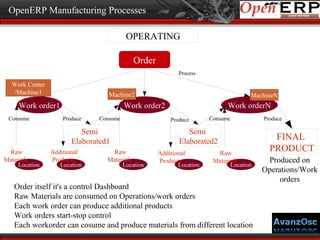

OpenERP provides improved manufacturing processes functionality including:

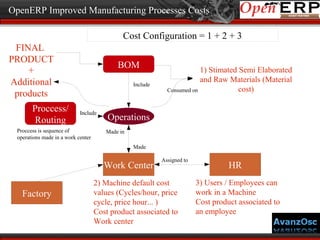

1) Configuring bills of materials (BOM), routings that define production processes as sequences of operations, work centers where operations occur, and costs.

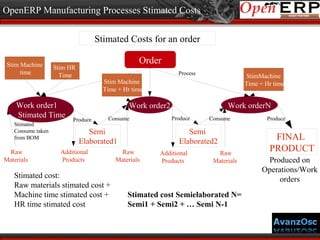

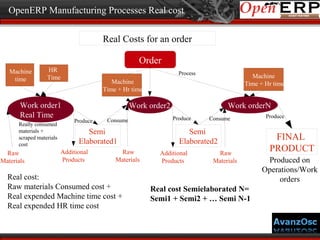

2) Managing production using work orders that consume raw materials and produce finished and additional products while tracking actual time and costs.

3) Estimating costs for orders based on BOM, work center costs, and estimated operation times, then calculating actual costs based on materials, time and costs consumed.