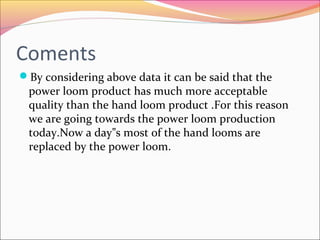

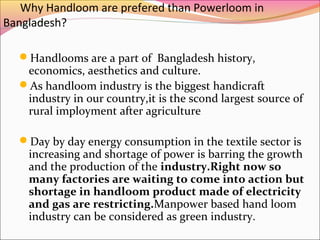

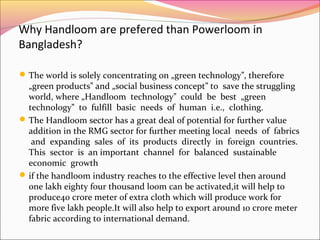

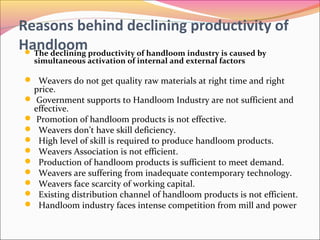

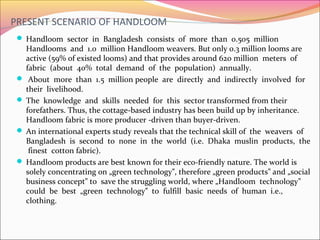

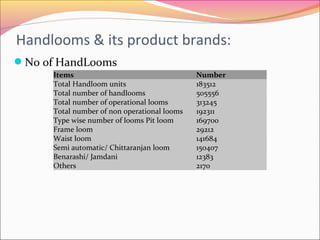

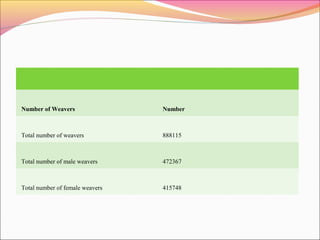

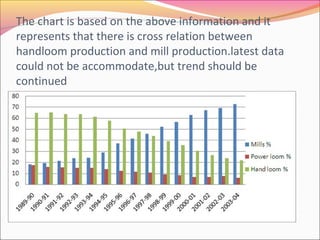

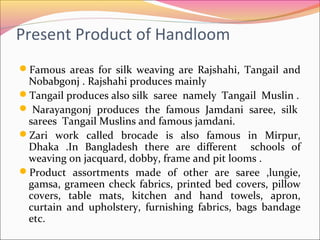

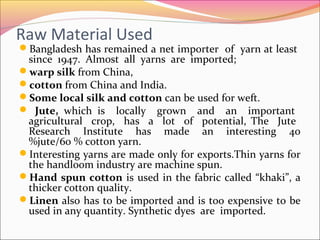

The handloom weaving industry in Bangladesh is a crucial cottage industry that provides significant rural employment and income, with over 1 million weavers and 0.505 million handlooms, although only about 59% are active. Despite its eco-friendly advantages and cultural significance, the sector faces declining productivity due to factors such as insufficient government support and competition from power looms. Recommendations for improvement include monitoring raw material pricing, providing specialized training for weavers, and creating promotional initiatives to enhance the industry's competitiveness.

![Analyse some properties of fabric manufactured

from power loom and handloom

To judge fabric performance we have to work with

the following parameter:

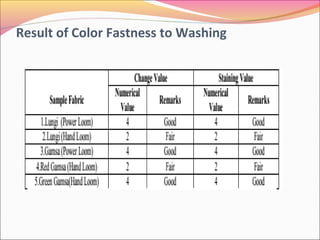

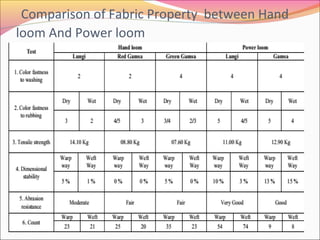

[1] Color fastness to washing

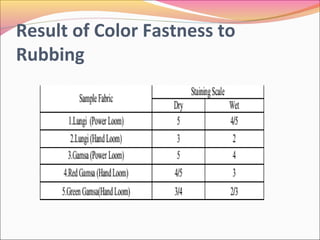

[2] Color fastness to rubbing

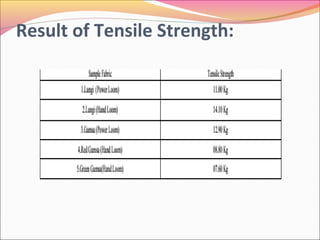

[3] Tensile strength

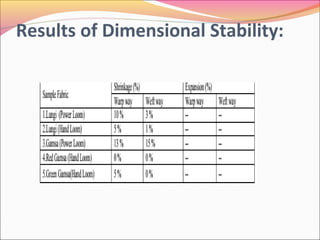

[4] Dimensional stability

[5] Abrasion resistance

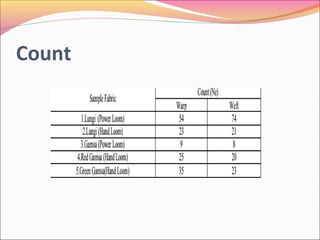

[6] Count

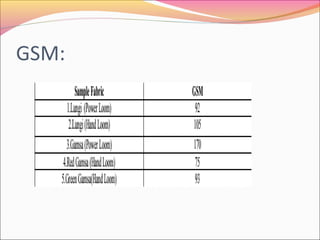

[7] GSM](https://image.slidesharecdn.com/fabricproperties-150613153251-lva1-app6892/85/Fabric-Properties-17-320.jpg)