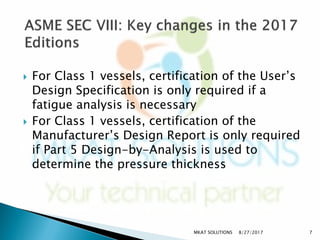

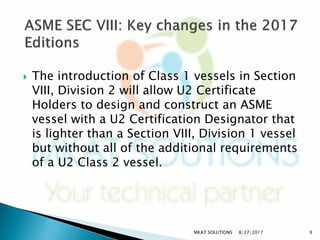

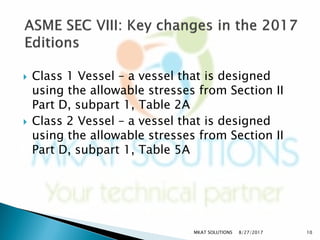

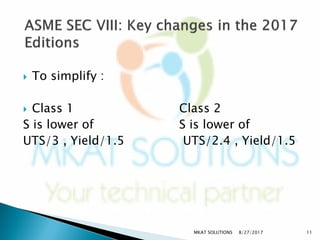

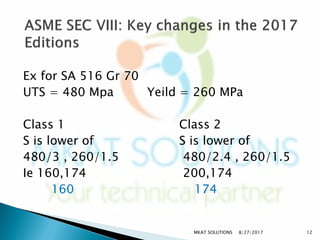

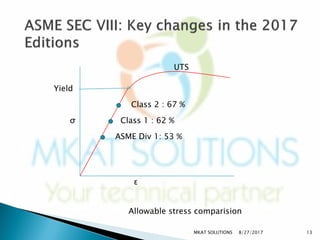

The document discusses changes between different versions of the ASME Section VIII Code for pressure vessels. Major changes include introducing two vessel classes - Class 1 and Class 2, with Class 1 having a higher design margin of 3.0 compared to Class 2's 2.4. Reinforcement rules for openings were moved to a new section. Material SA-299 was added and figures were included for expansion joints. Allowable stresses are now based on different tables for each class.