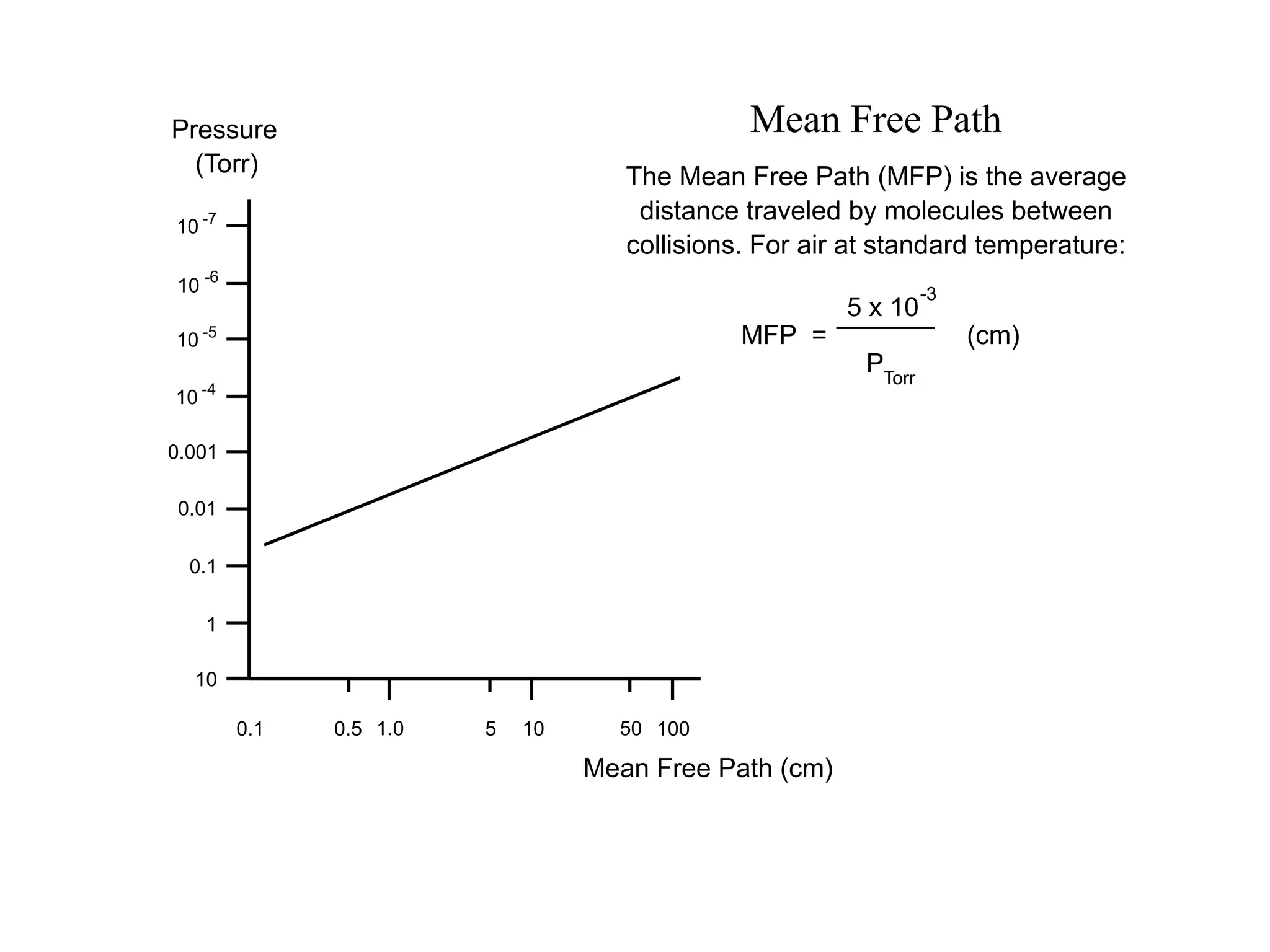

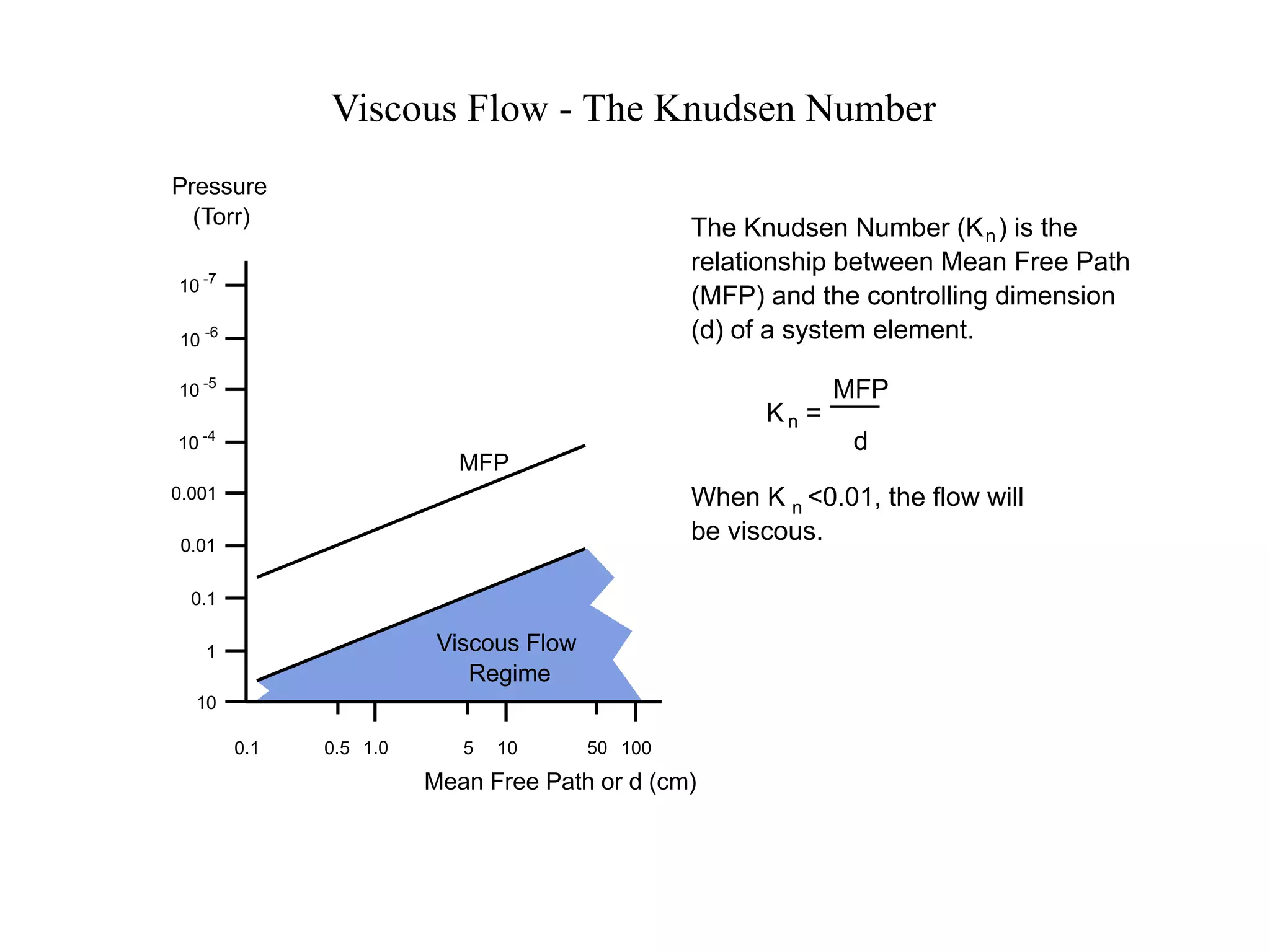

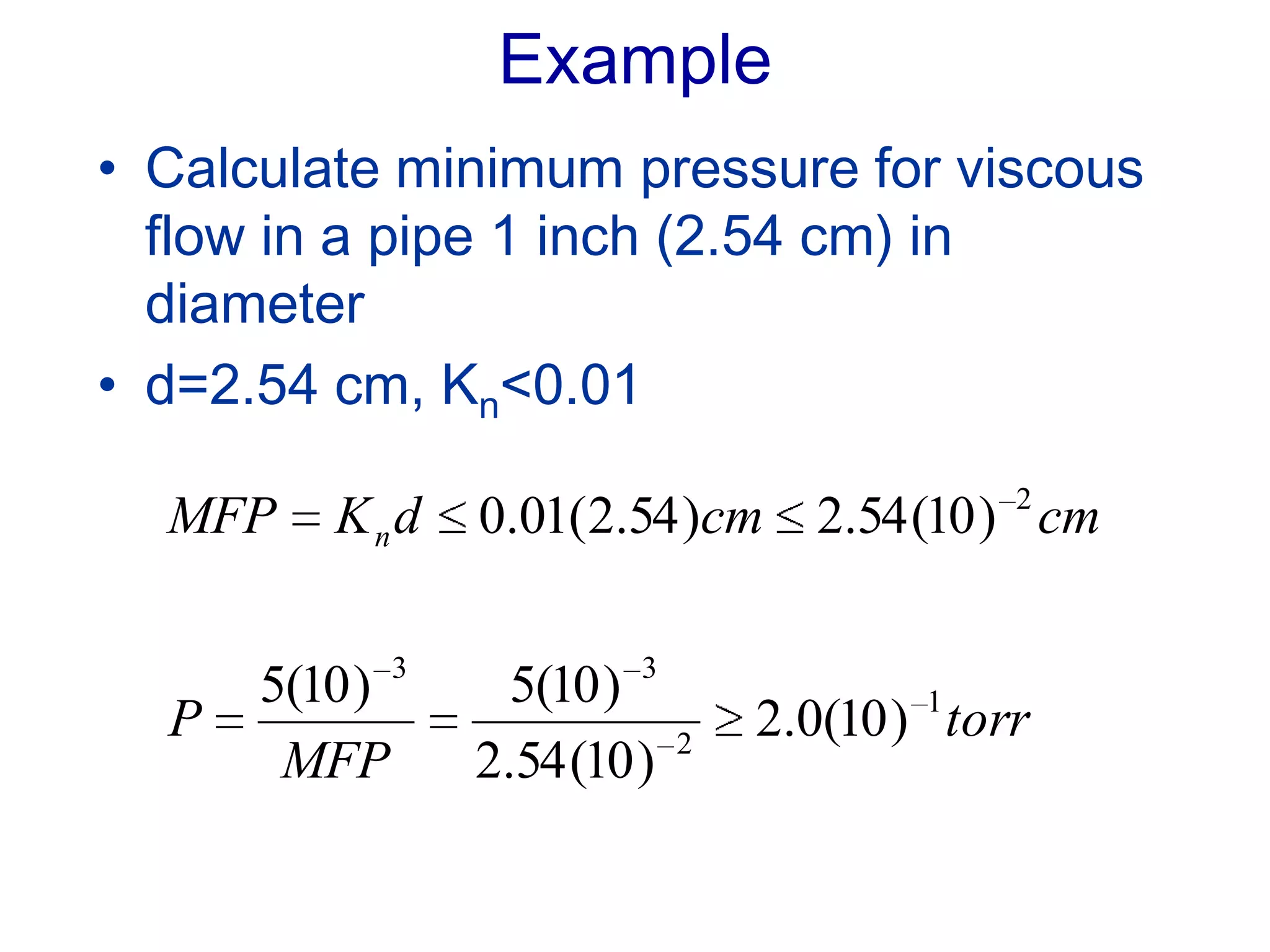

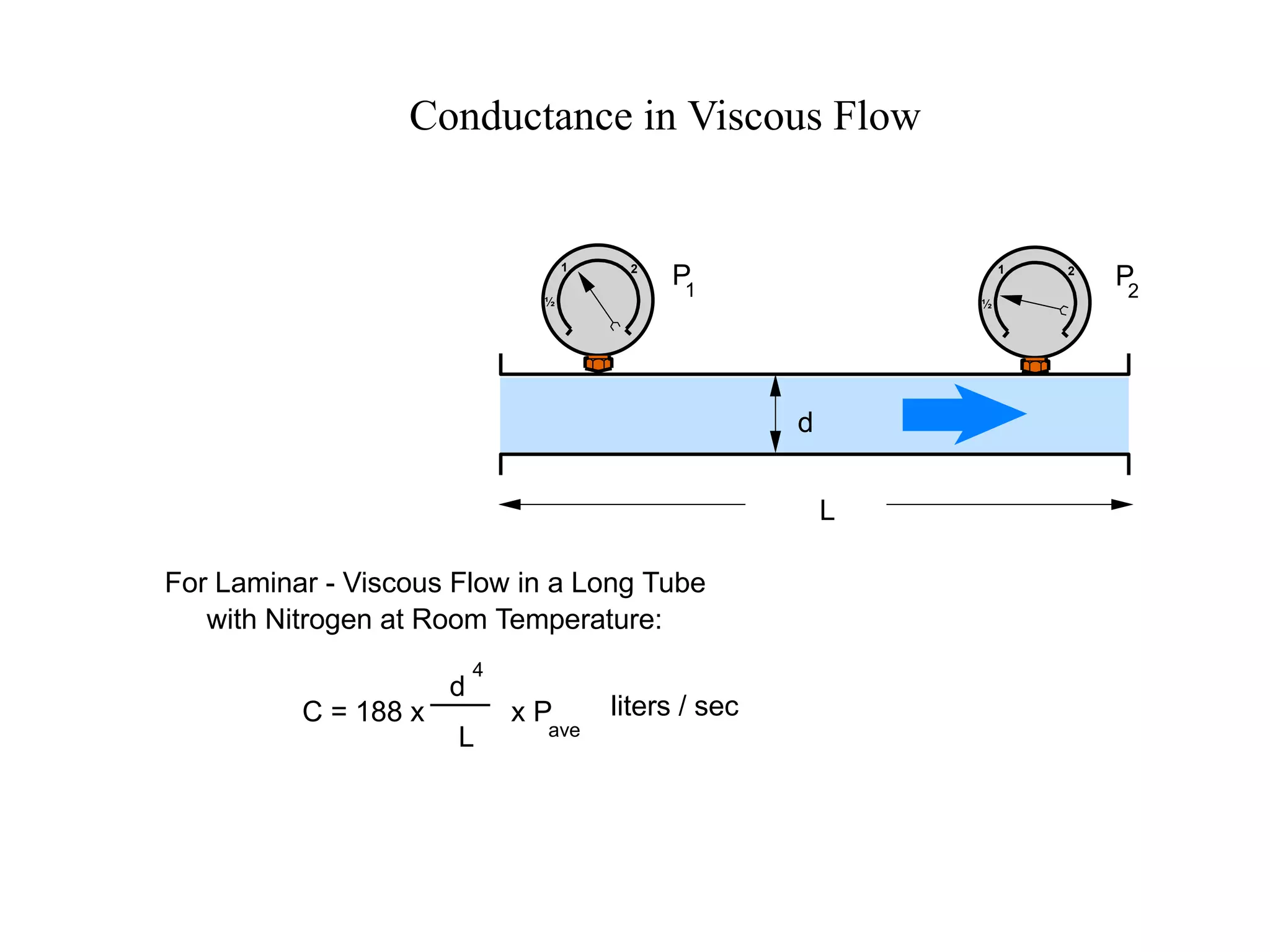

The minimum pressure for viscous flow in a 1 inch diameter pipe is approximately 5 Torr.

At 5 Torr, the mean free path is 0.2 cm.

The Knudsen number is then:

Kn = MFP/d

= 0.2 cm / 2.54 cm

= 0.078

Since Kn < 0.01, the flow will be viscous at or below 5 Torr pressure.