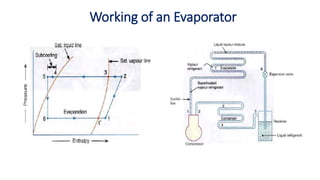

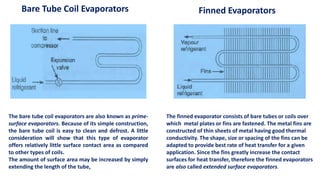

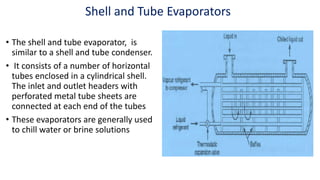

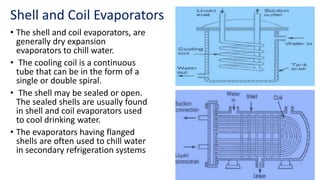

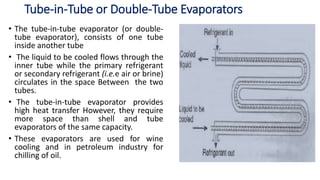

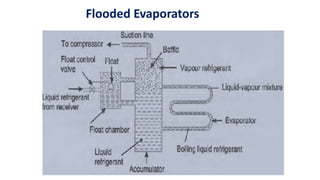

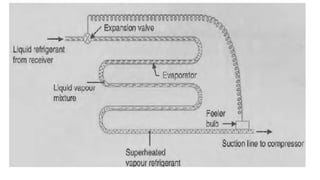

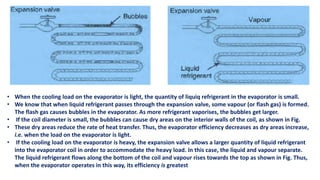

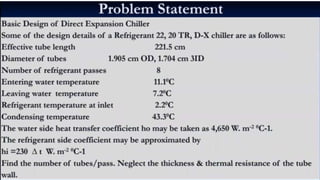

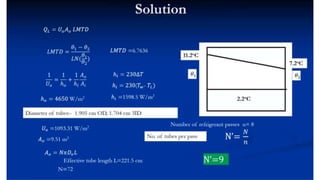

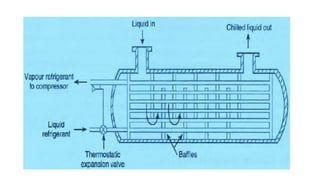

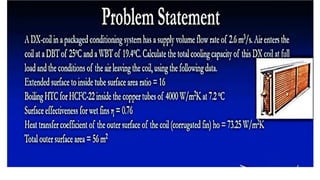

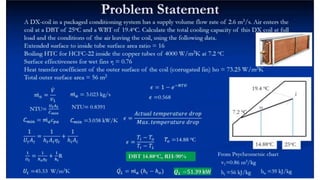

The document discusses the thermal design of refrigeration system components, specifically evaporators, which are critical in the low pressure side of refrigeration systems for heat absorption. It details various types of evaporators such as bare tube, finned, shell and tube, and flooded evaporators, along with factors affecting their heat transfer efficiency. Additionally, it contrasts flooded evaporators with dry expansion evaporators in terms of efficiency and operational considerations.