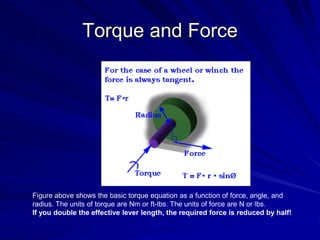

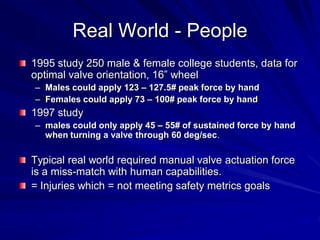

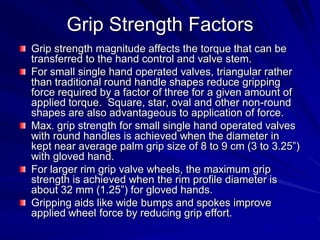

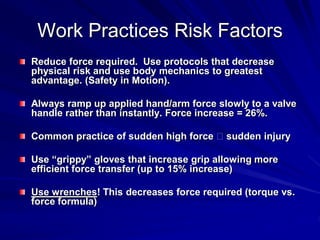

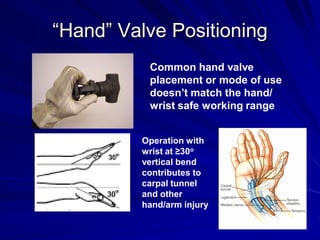

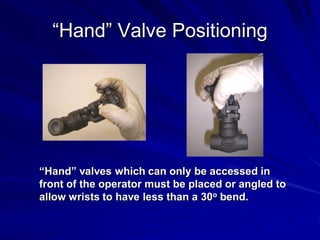

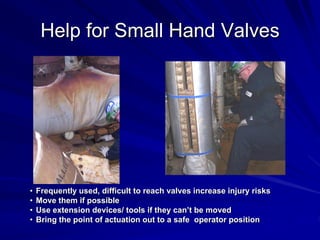

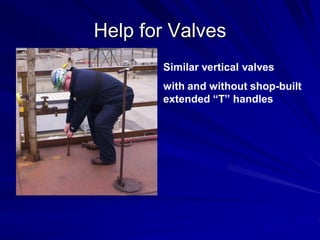

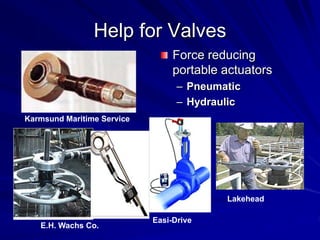

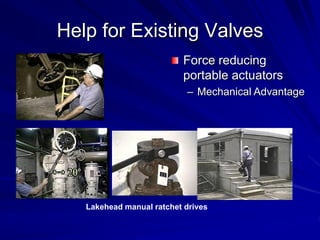

This document discusses ergonomic considerations for reducing physical demands when operating valves. It evaluates valve torque requirements, tools that can reduce required force, human force capabilities, and optimal valve positioning and design. The goals are to prevent overexertion and repetitive motion injuries by controlling risks and ensuring valve operation stays below human strength limits. Tools like pneumatic actuators, extended handles, and wrenches can help reduce required forces and improve body mechanics. Proper valve placement and orientation also influences exertion levels.