This document discusses how to technically complete a production order in SAP. It provides instructions on:

- Performing necessary checks before closing a production order by using transactions like CO03, COHV, and COOIS to monitor production order status.

- Understanding how technically completing a production order signals that production is finished and releases materials and capacity reservations.

- Reconciling confirmed and receipted quantities daily to accurately record production data in real-time.

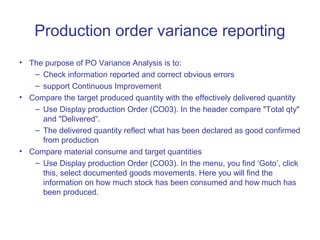

- Analyzing production order variances by comparing target and actual quantities produced using transaction CO03 to identify errors and support continuous improvement.