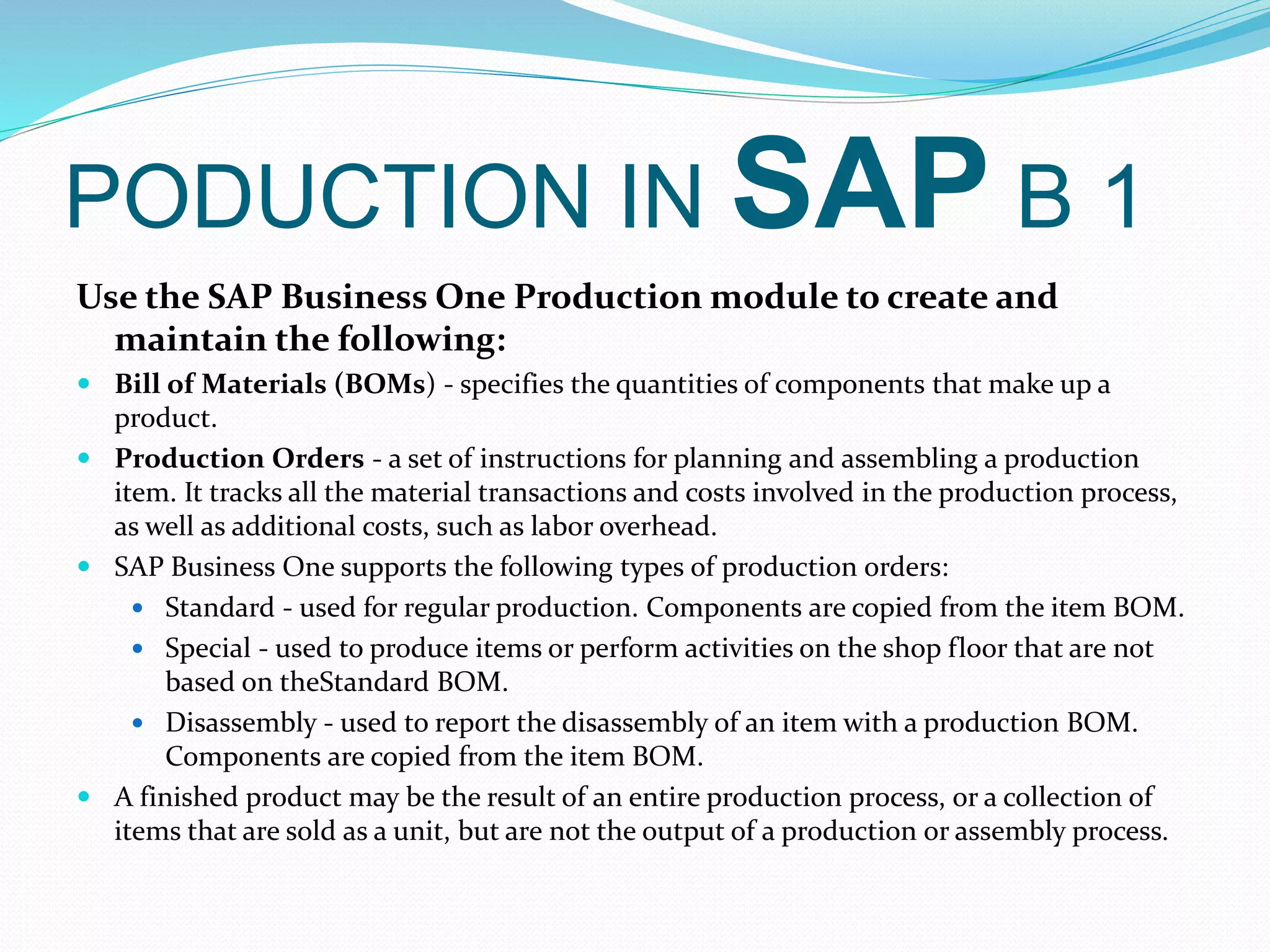

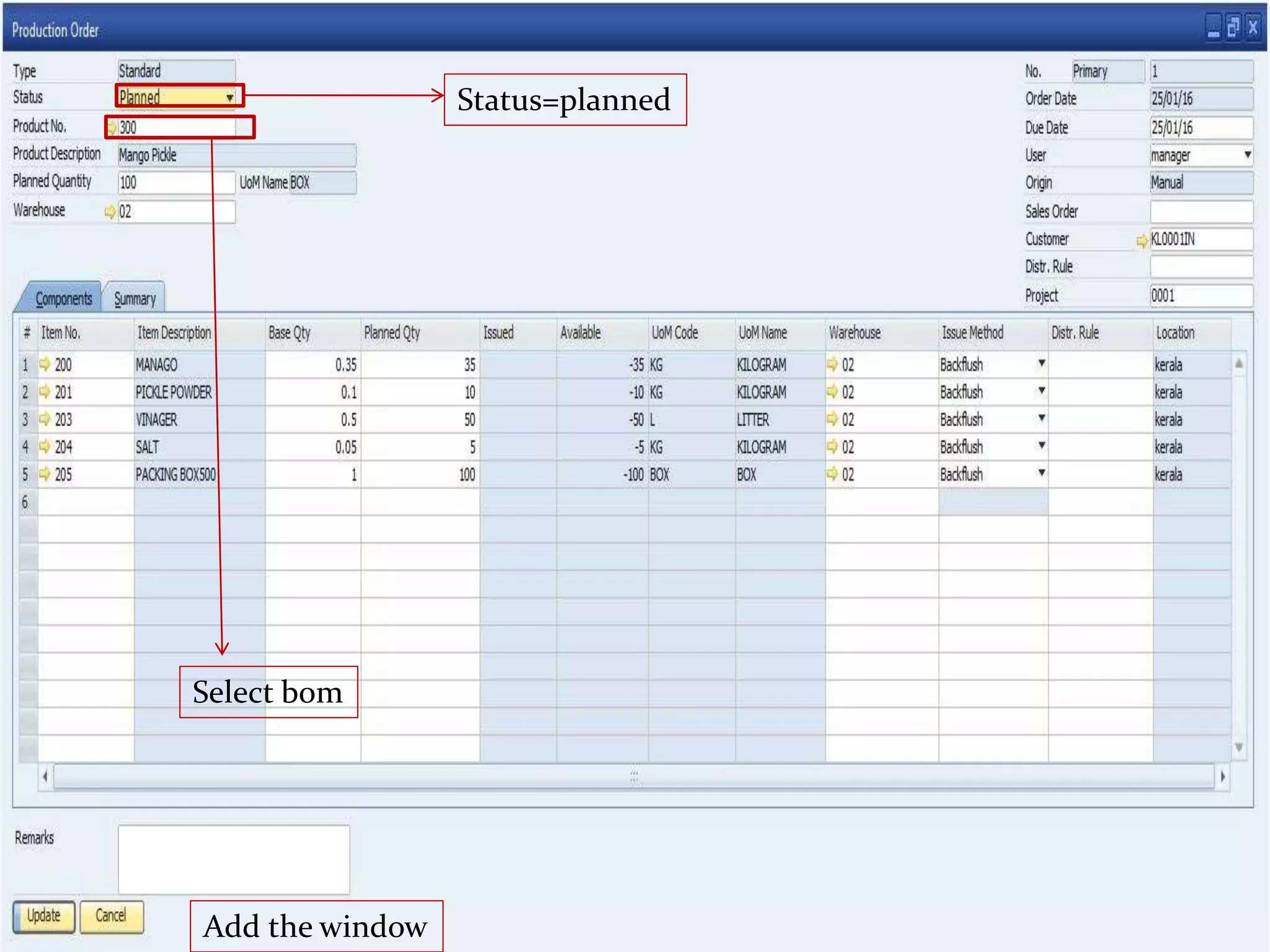

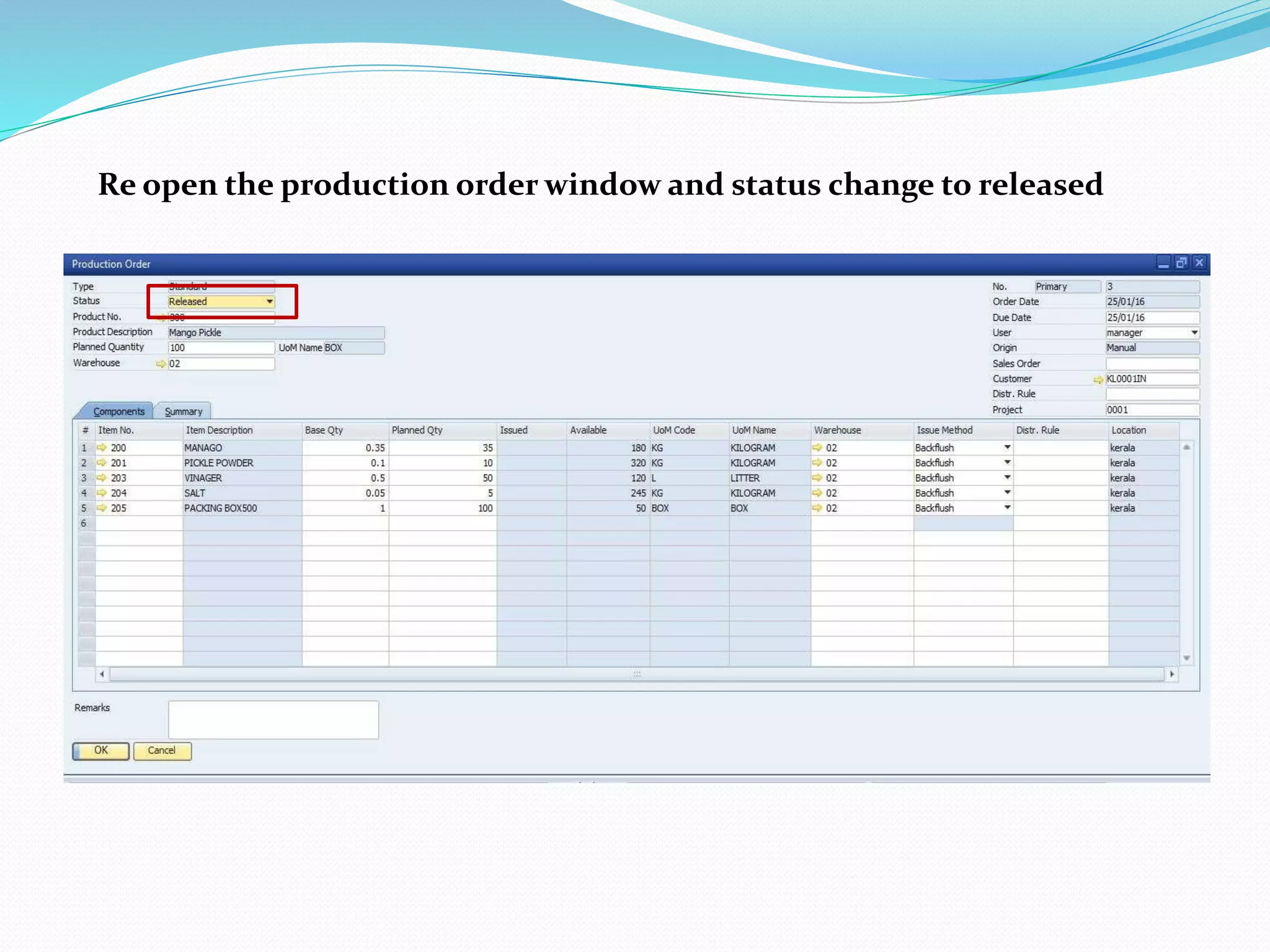

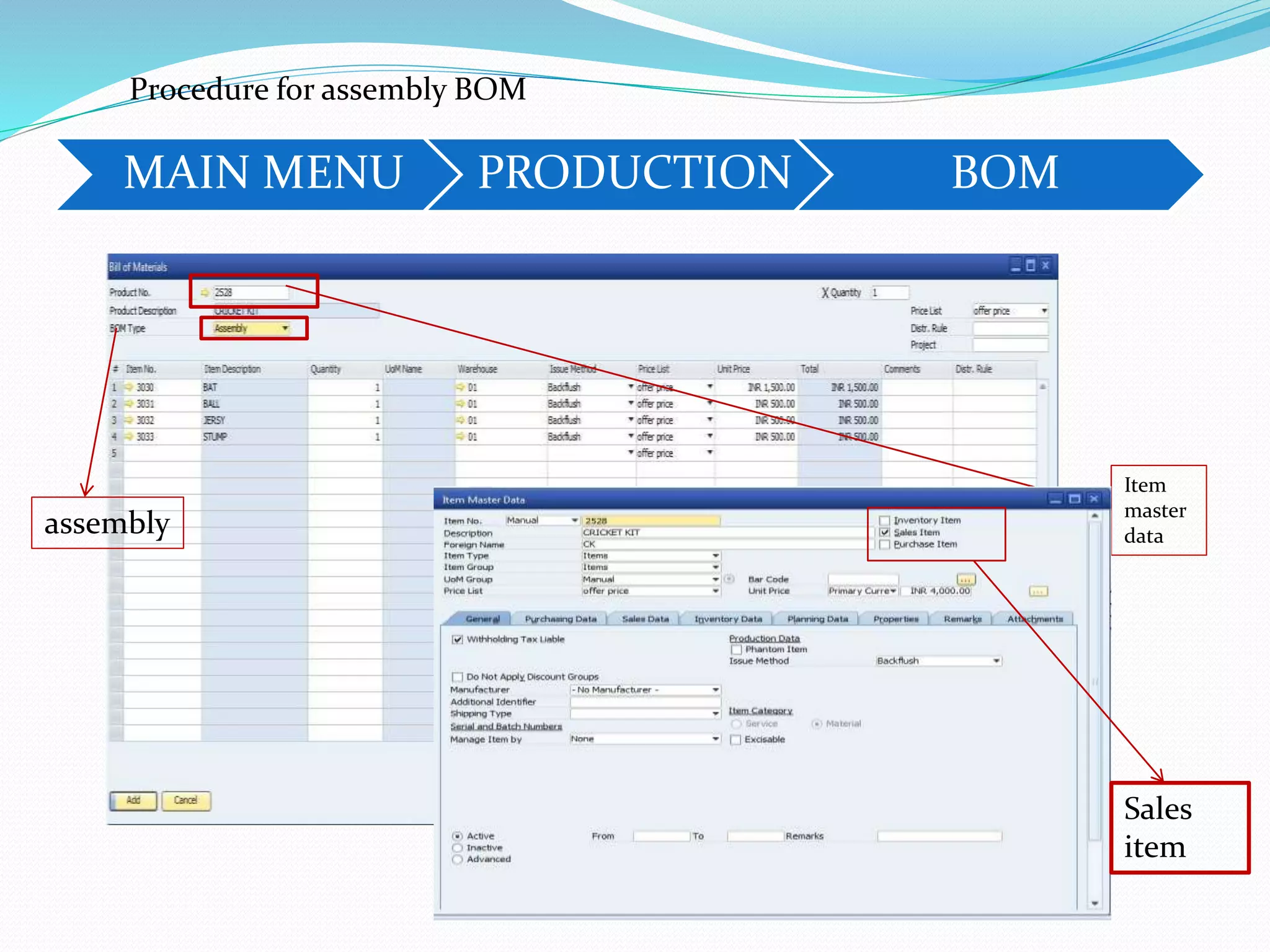

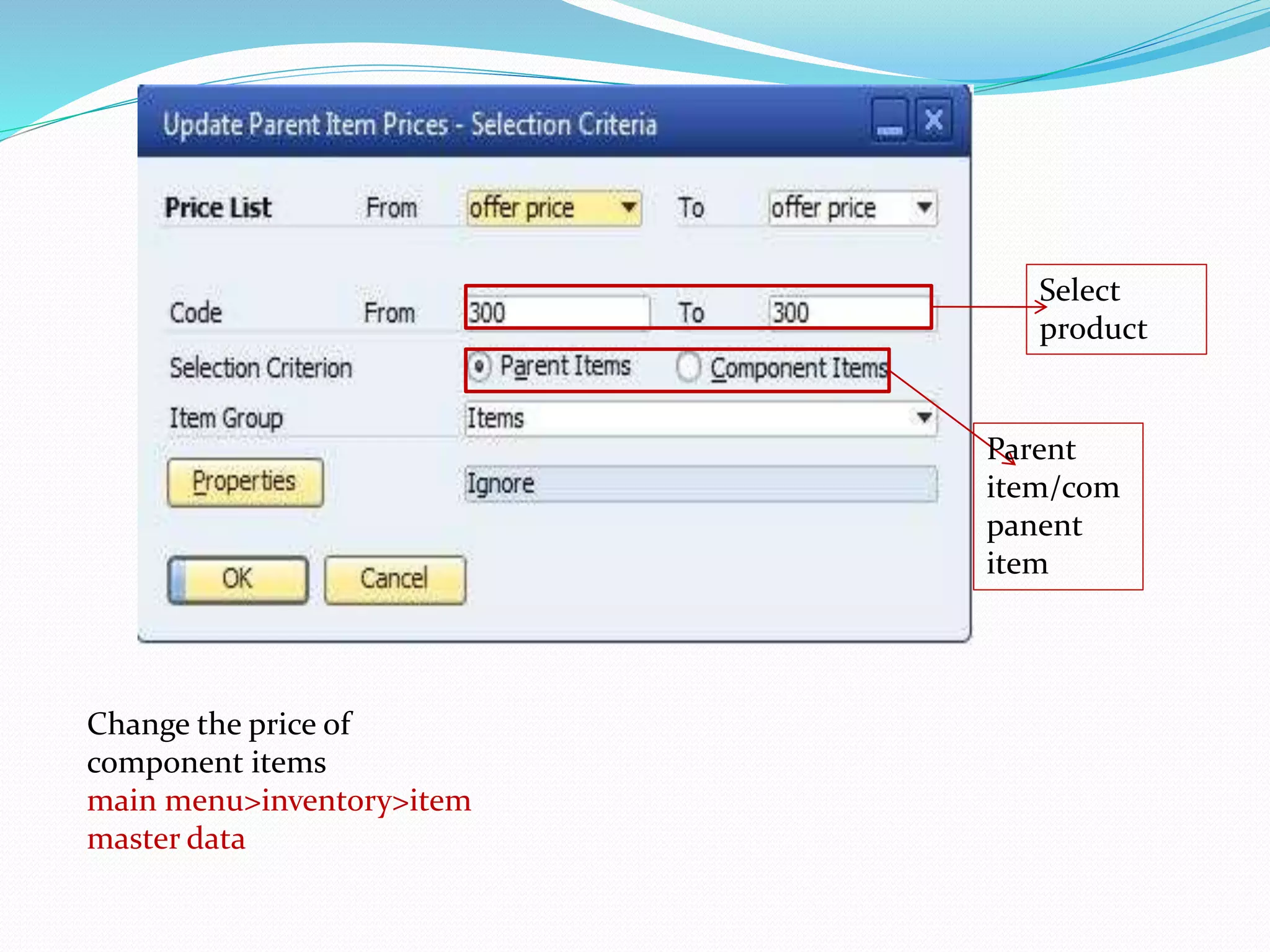

The document discusses SAP Business One's production module. It describes how the module allows users to create bills of materials (BOMs) and production orders to manage production processes. Key features covered include creating BOMs, different types of production orders, issuing and receiving items for production, and production reports. The production module aims to simplify production management, improve efficiency, customer service, and reduce inventory costs.