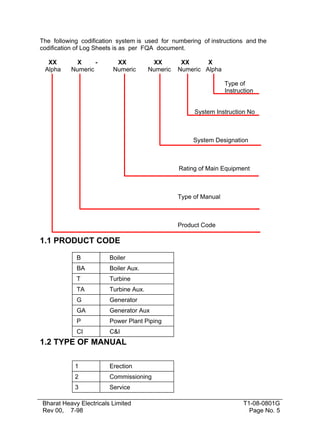

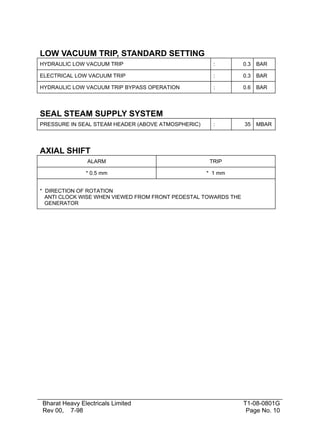

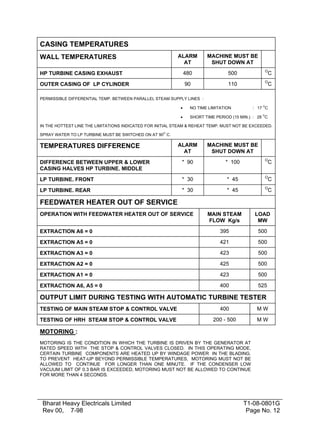

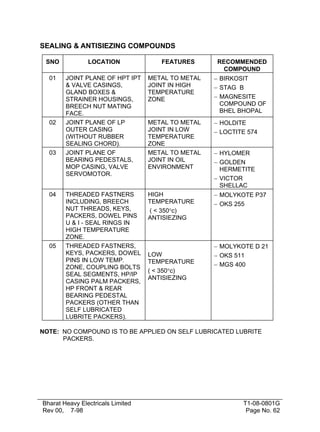

This document provides technical data for the erection of a 500 MW steam turbine from KWU design. It includes specifications for the turbine construction including cylinders, valves, speeds, pressures, temperatures, and limitations. Key details include it being a three cylinder reheat condensing turbine with 17 reaction stages in the high pressure cylinder and 12 reaction stages per flow in the double flow intermediate pressure cylinder. The rated steam conditions and permissible operating values are also provided.