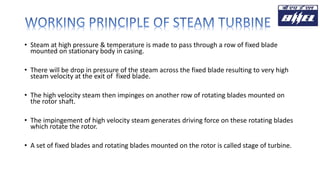

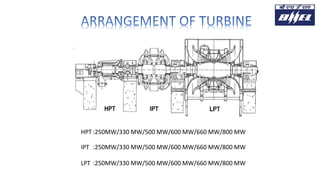

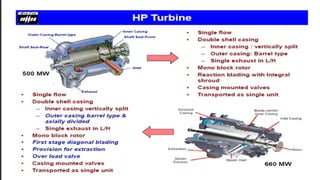

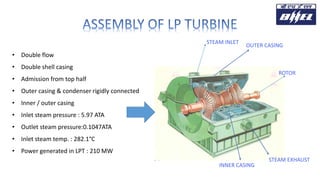

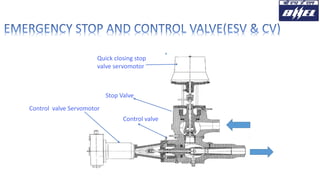

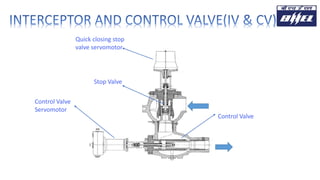

This presentation provides an overview of steam turbine manufacturing by Bharat Heavy Electricals Limited (BHEL). It discusses BHEL's history and awards, introduces steam power plants and the function of turbines. It then describes the key components of steam turbines like HP, IP, LP blades and their assembly. The control valves that regulate steam flow are also explained. In conclusion, it highlights the benefits of BHEL's steam turbine manufacturing process like improved safety, reduced breakdowns and a better work environment.