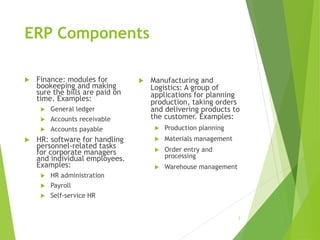

Enterprise resource planning (ERP) systems integrate various business functions and departments into a single system. ERP combines databases across departments into a single database accessible by all employees. It automates tasks involved in business processes. Major ERP components include finance, human resources, and manufacturing/logistics modules. Leading ERP vendors include SAP, Oracle, and Microsoft. ERP aims to integrate financial data, standardize processes, and centralize HR information. Successful ERP implementation requires top management support, extensive training, and viewing implementation as an ongoing process.