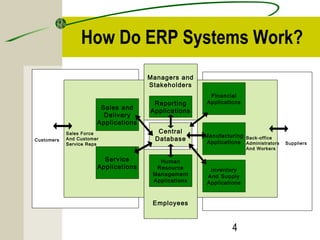

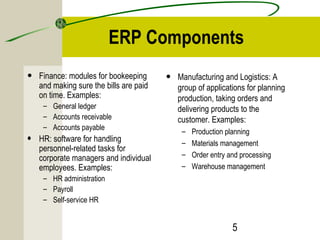

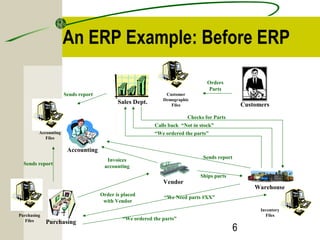

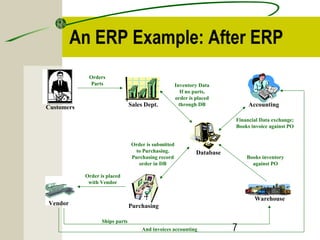

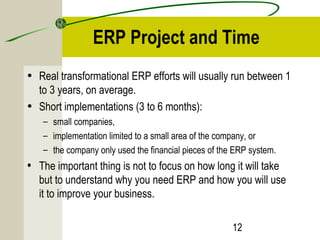

This document discusses Enterprise Resource Planning (ERP) systems. ERP systems combine databases across departments into a single database that can be accessed by all employees to automate business processes. The document outlines the components and implementation of ERP systems, noting that while ERP systems can integrate data and standardize processes to realize benefits, implementation requires significant costs, time, and risks management. Best practices for a successful ERP implementation include aligning the system with business strategy and processes, gaining executive support, training users, and viewing implementation as an ongoing process of learning and adaptation.