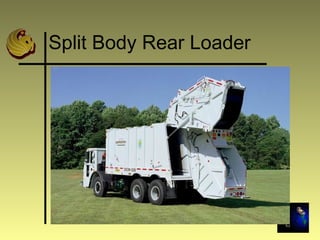

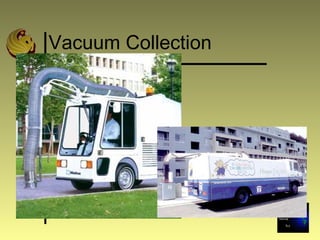

The document discusses waste collection systems. It begins by outlining the history of waste collection from wagons to modern trucks. It then describes the development of collection technologies over time, from open trucks to covered vehicles to rear loaders and automated systems. The document outlines different types of collection systems for residential, commercial, and recyclable waste. It discusses factors that affect collection design and costs such as climate, density, and vehicle routes. Safety concerns are also reviewed.