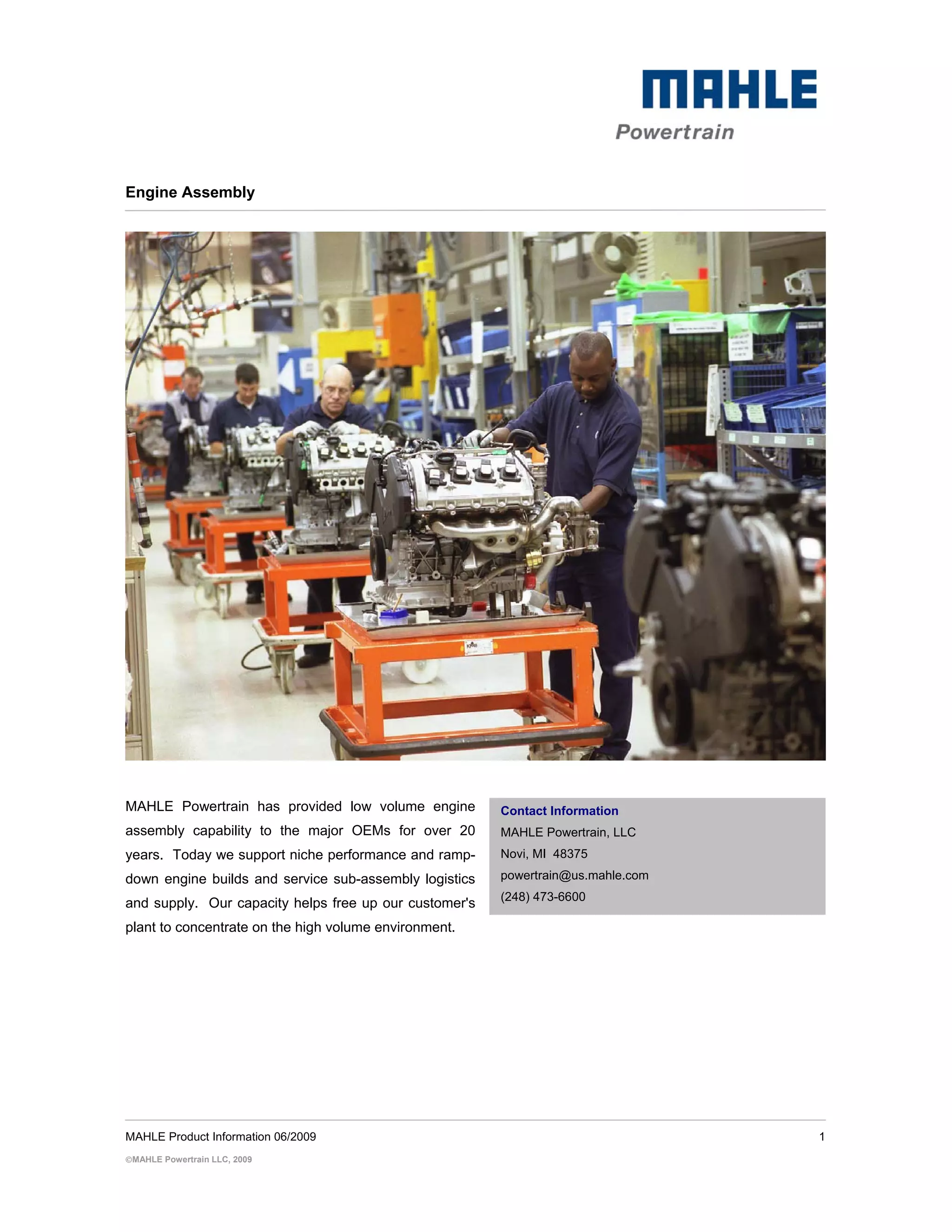

MAHLE Powertrain has provided low volume engine assembly for over 20 years to major automakers. They support niche performance and end-of-life engine builds, as well as subassembly logistics. Their capacity allows customers to focus on high volume production. MAHLE uses a combination of manual and automated processes tailored to product volume and complexity, with quality control processes to ensure any issues are addressed. They have experience supporting customers from concept to manufacture across engine assembly programs.