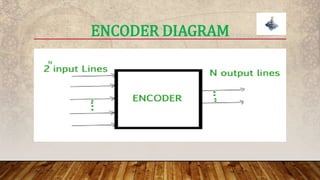

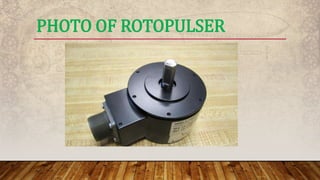

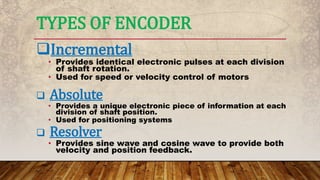

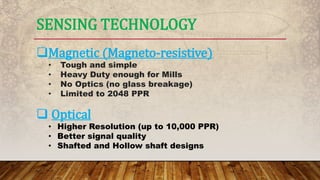

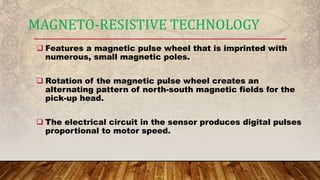

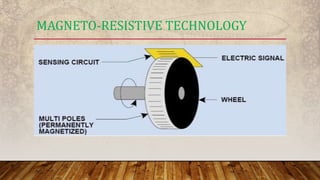

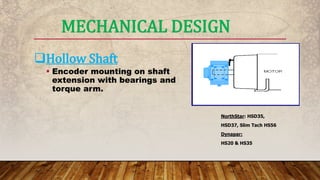

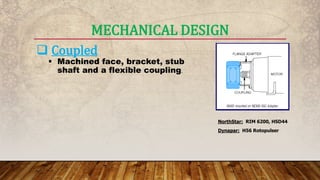

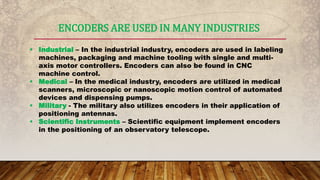

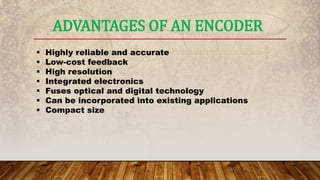

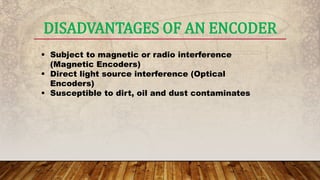

The document provides a comprehensive overview of encoders, detailing their definition, types, applications, and mechanical designs. Encoders are combinational circuits that convert multiple input lines to fewer output lines, and they are used in various industries including automotive, medical, and robotics. The text also discusses the advantages and disadvantages of encoders, emphasizing their reliability, accuracy, and potential interference issues.