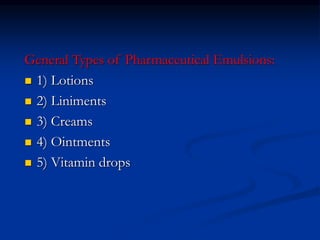

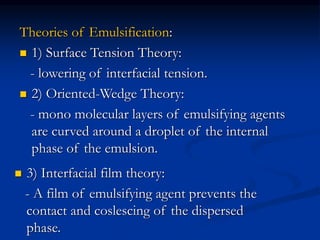

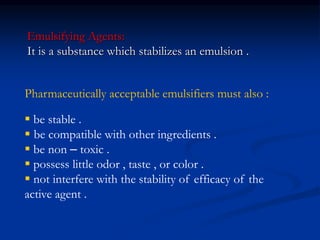

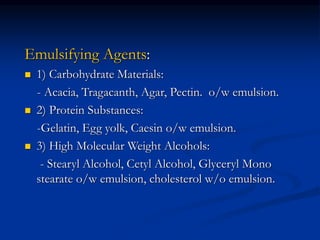

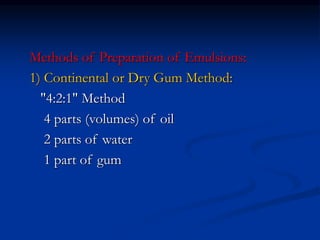

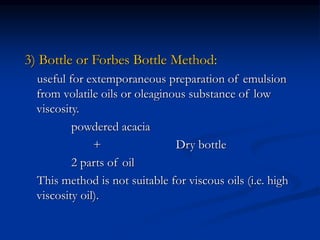

This document discusses emulsions, including their introduction, types, emulsifying agents, methods of preparation, tests for emulsion types, stability, phase inversion, and breaking. An emulsion is a dispersion of small liquid globules within another immiscible liquid, classified as oil-in-water or water-in-oil emulsions. Emulsions are stabilized using emulsifying agents like carbohydrates, proteins, alcohols, or surfactants. Their stability depends on factors like interfacial film properties, electrical barriers, viscosity, droplet size distribution, and temperature. Phase inversion can occur by changing the order of addition, emulsifier properties, or phase ratios.