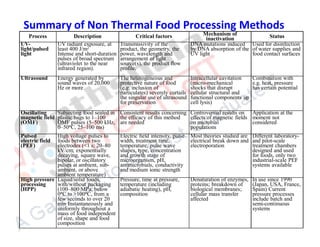

This document discusses various non-thermal food processing methods including ohmic heating, pulsed electric fields, high pressure processing, pulsed light, ultrasound, oscillating magnetic fields, and irradiation. It describes the objectives and mechanisms of each method, providing details on how each technique works to reduce microbes while maintaining quality attributes like color, flavor and texture. The conclusion states that non-thermal methods are useful for liquid foods and large-scale production but have high equipment costs, and that reducing costs could enable broader application in small industries.