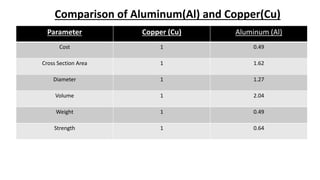

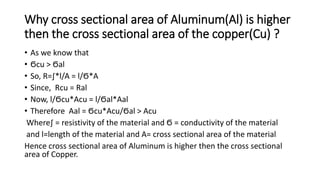

This document discusses different types of electrical materials including conducting, magnetic, and insulating materials. It focuses on copper and aluminum as highly conducting materials. Copper has the highest conductivity but is more expensive than aluminum. While aluminum has lower conductivity than copper, it has a higher cross-sectional area for the same resistance due to its lower cost and abundance. Aluminum is increasingly being used instead of copper in electrical applications due to its lower cost, although copper remains more commonly used for applications requiring high conductivity like motor windings.