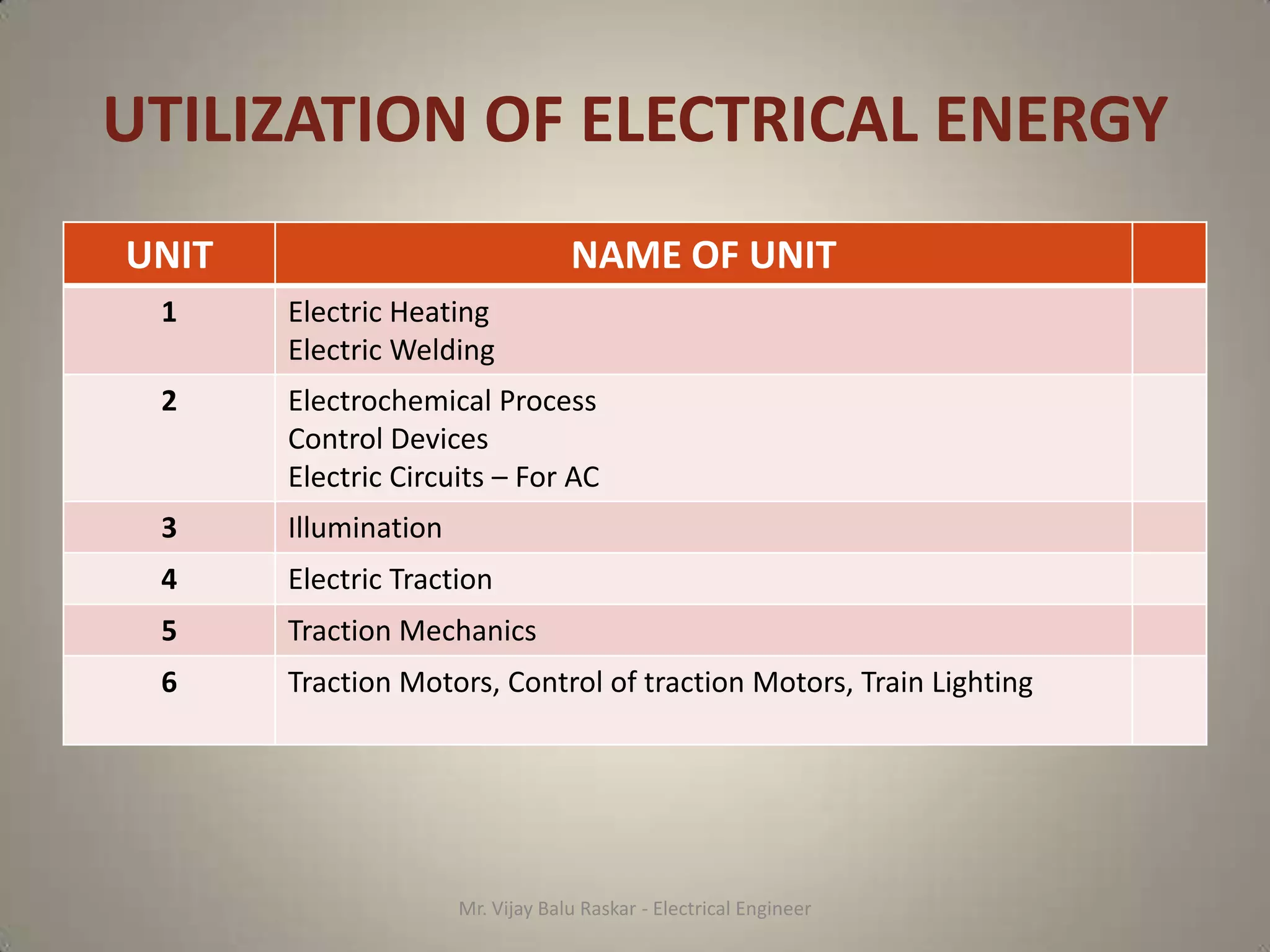

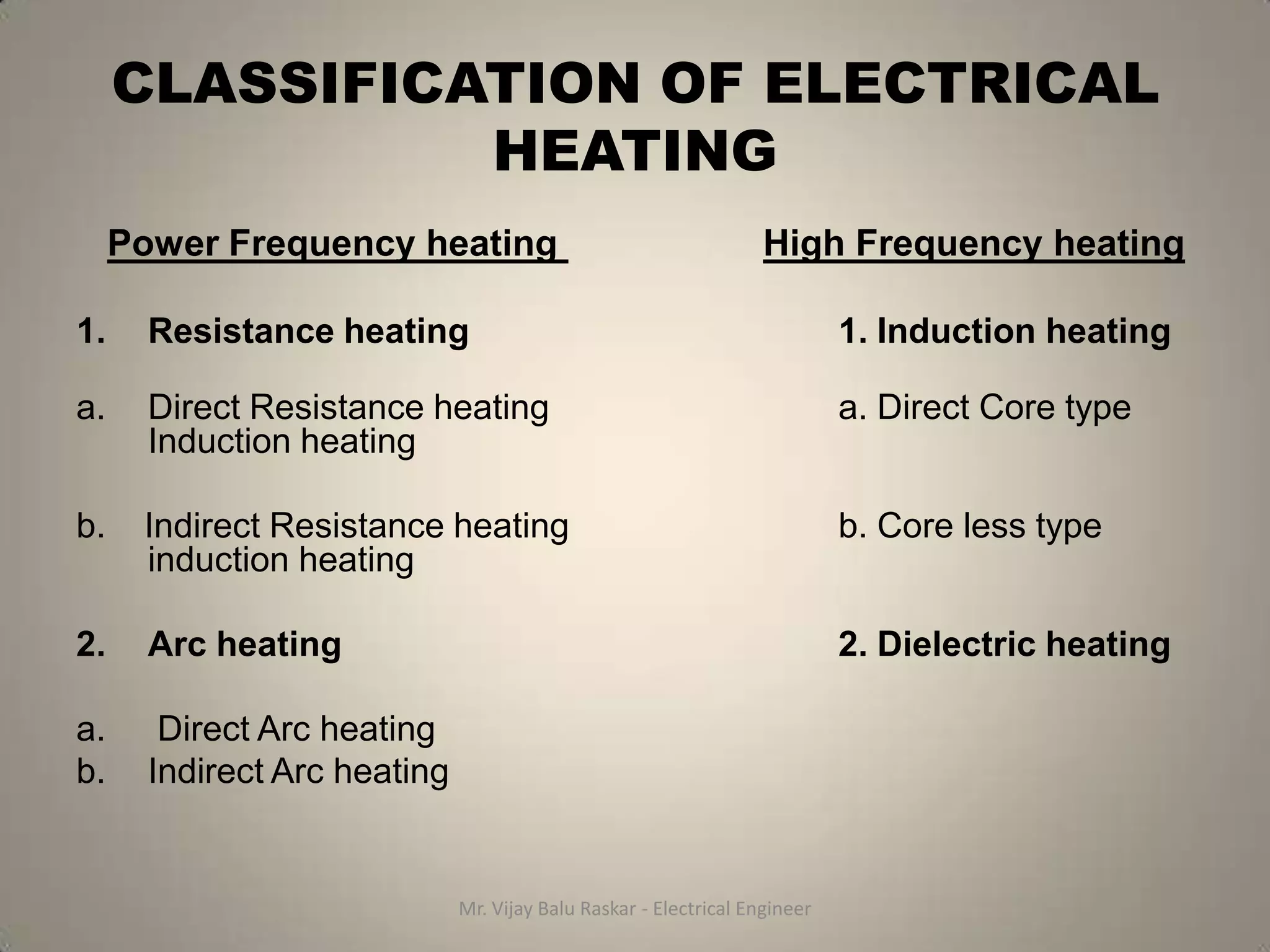

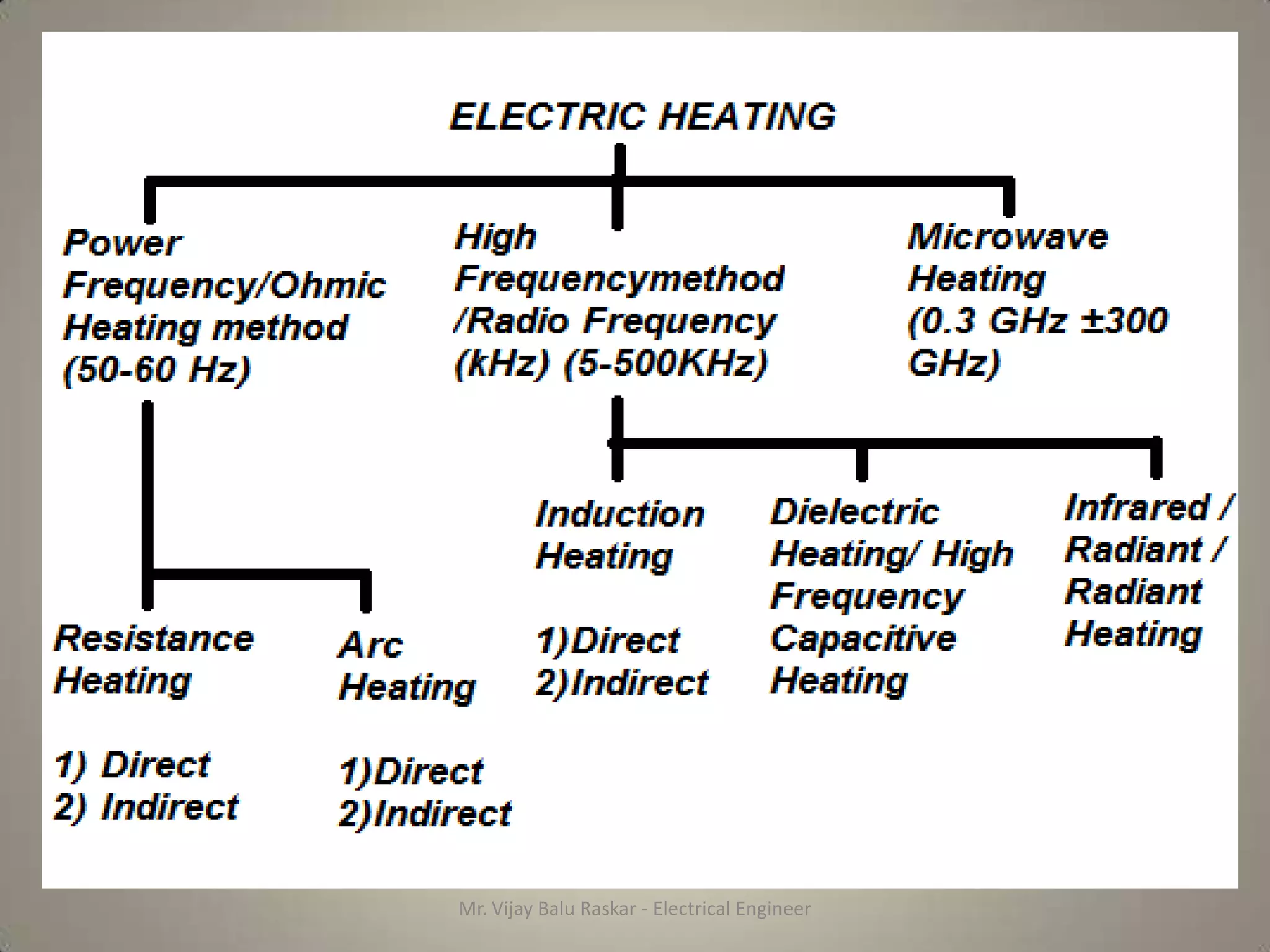

1. The document discusses different methods of utilizing electrical energy, grouping them into 6 units: electric heating, electrochemical processes, control devices, electric circuits, illumination, and electric traction.

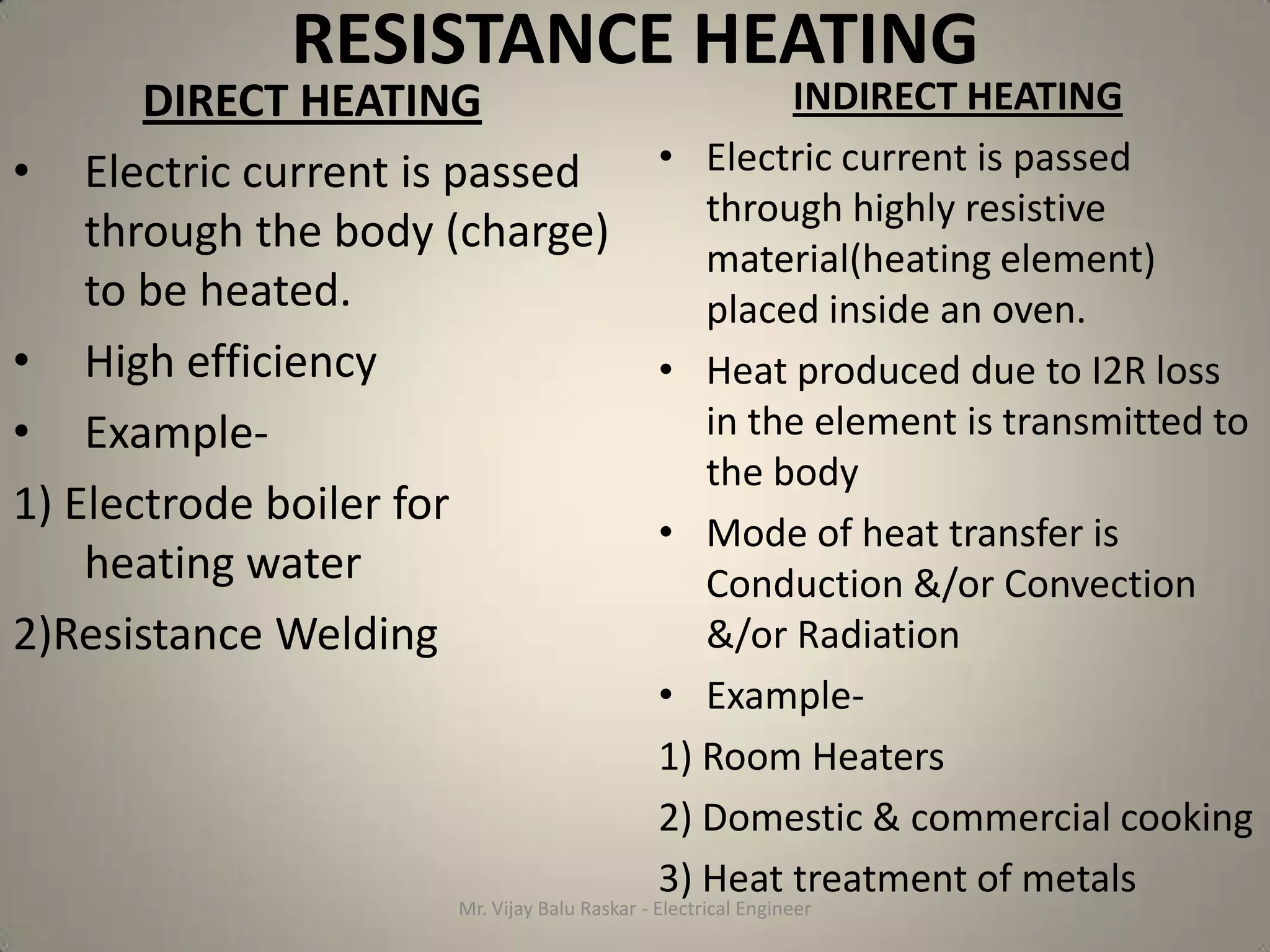

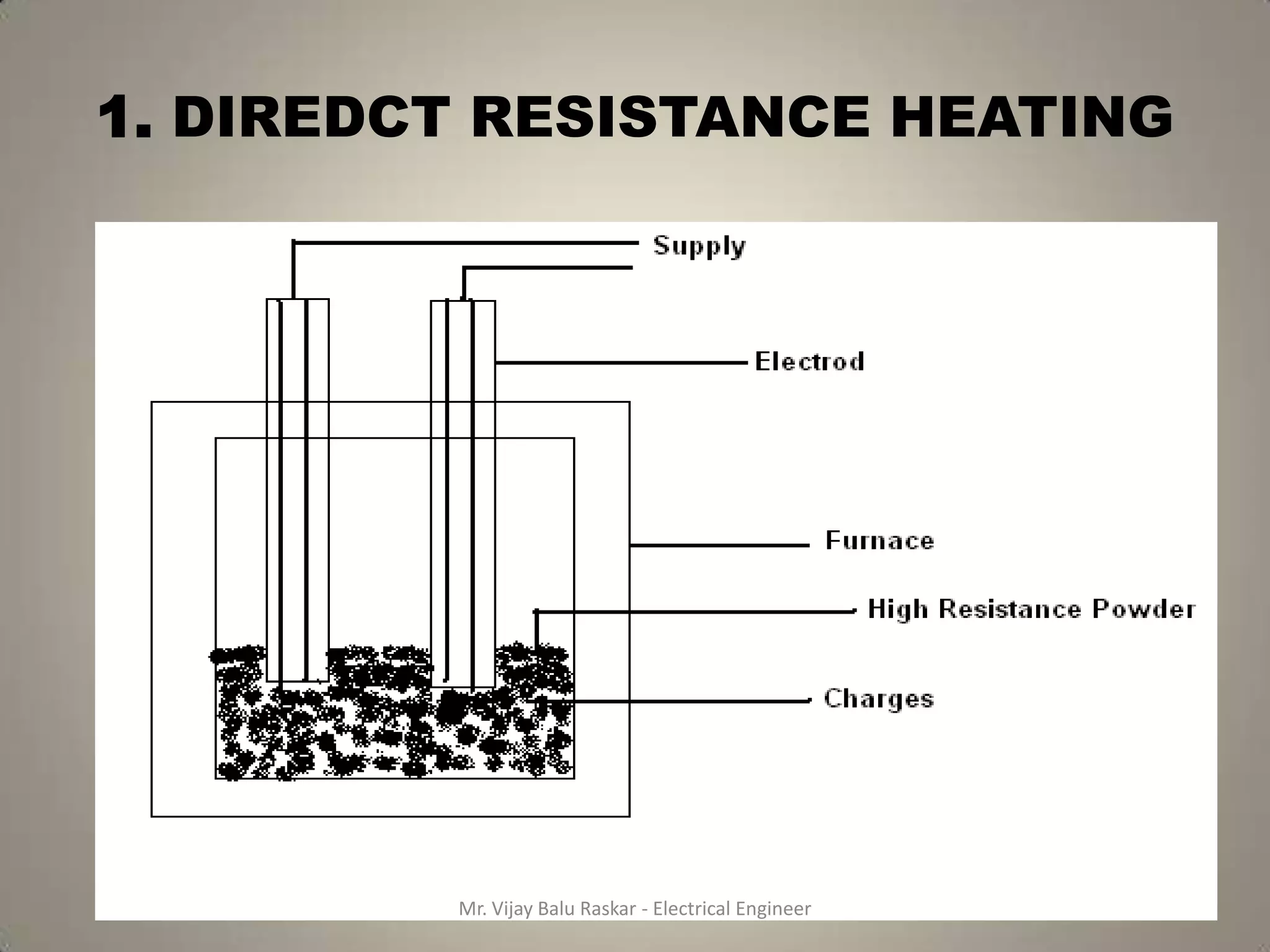

2. It provides examples of domestic and industrial applications of electrical heating, which works on the principle of Joule heating by converting electrical energy into heat energy when a current passes through a resistor.

3. The advantages of electrical heating over other methods include being clean, causing no pollution, allowing accurate temperature control, and having high efficiency.