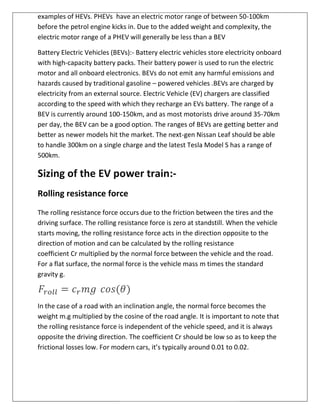

The document provides an overview of electric vehicles including their history and types. It discusses how the earliest electric vehicles emerged in the late 1800s and became popular in the early 1900s. It describes different types of electric vehicles such as hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs). It also discusses the key forces that affect electric vehicle power trains including rolling resistance, aerodynamic drag, and gradient forces due to road inclines.