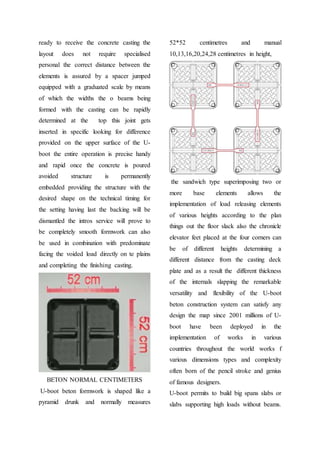

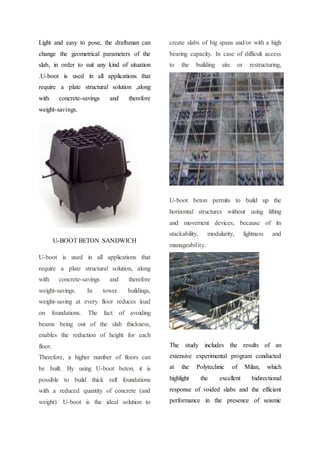

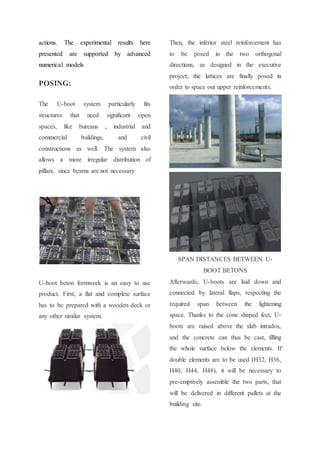

U-Boot technology is a formwork made of recycled polypropylene designed to create lightweight reinforced concrete slabs and foundations. It allows for the creation of "mushroom slabs" where the mushroom shape is embedded in the thickness of the slab. Using U-Boot formworks means that beams are not required, as loads can be transferred bidirectionally through the slab. This results in significant savings in concrete and reinforcement.