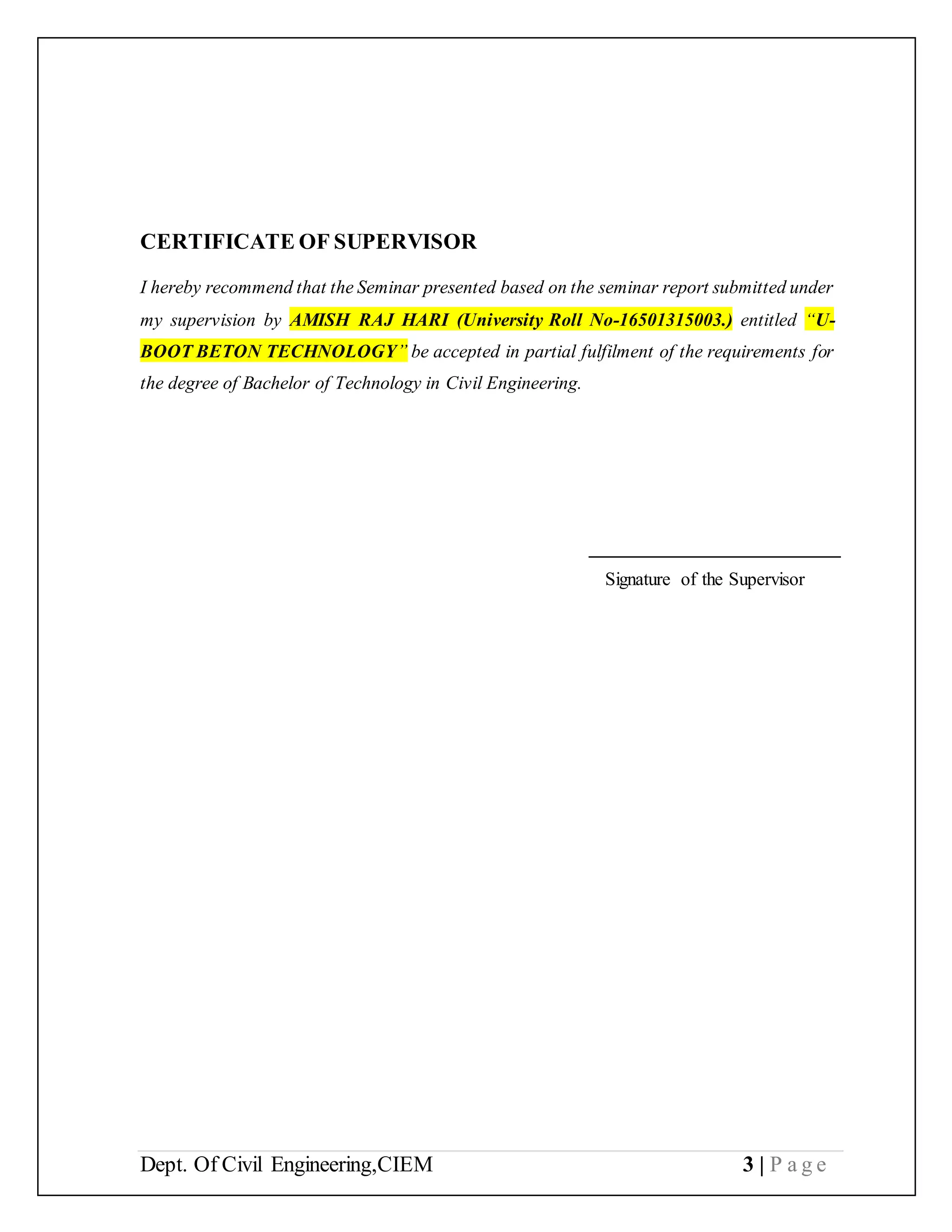

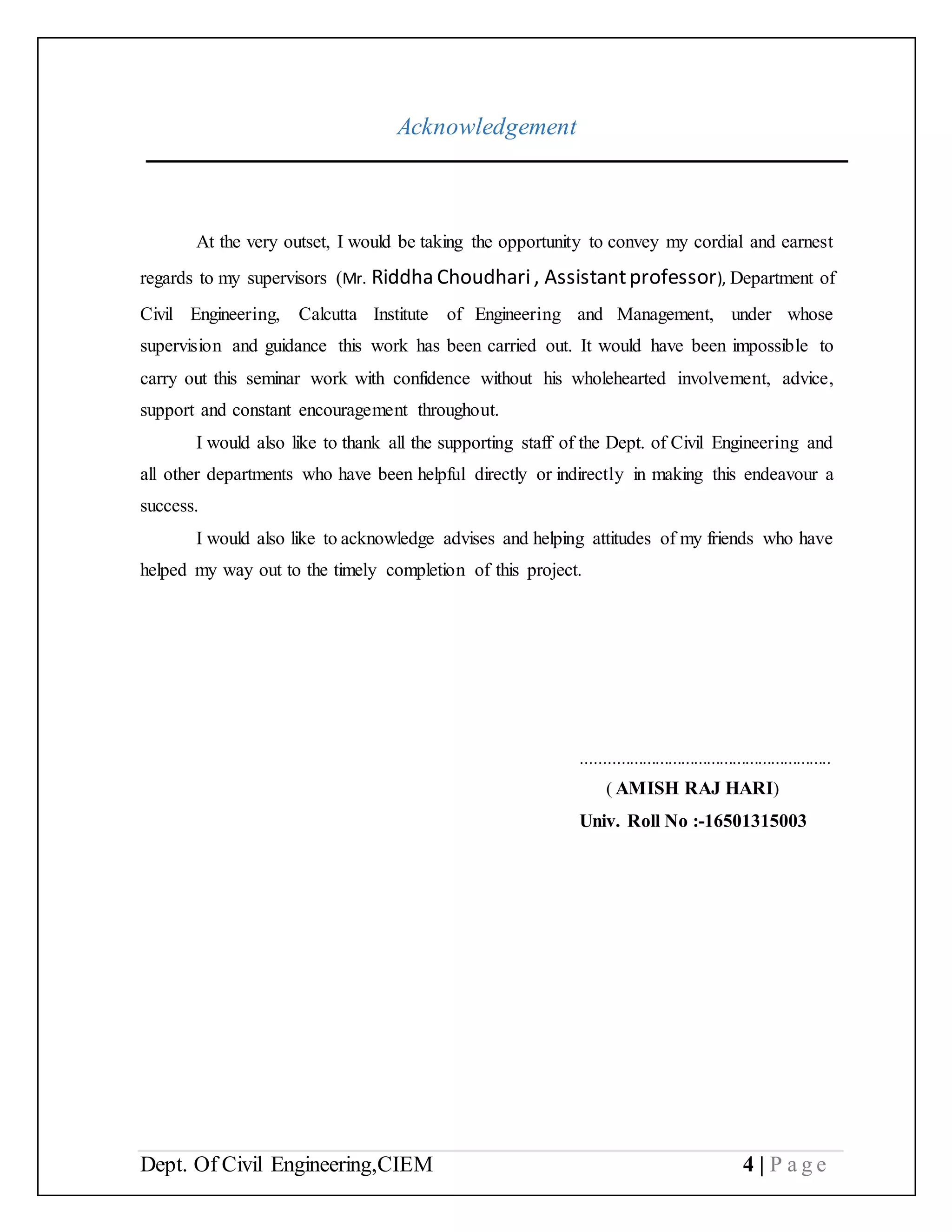

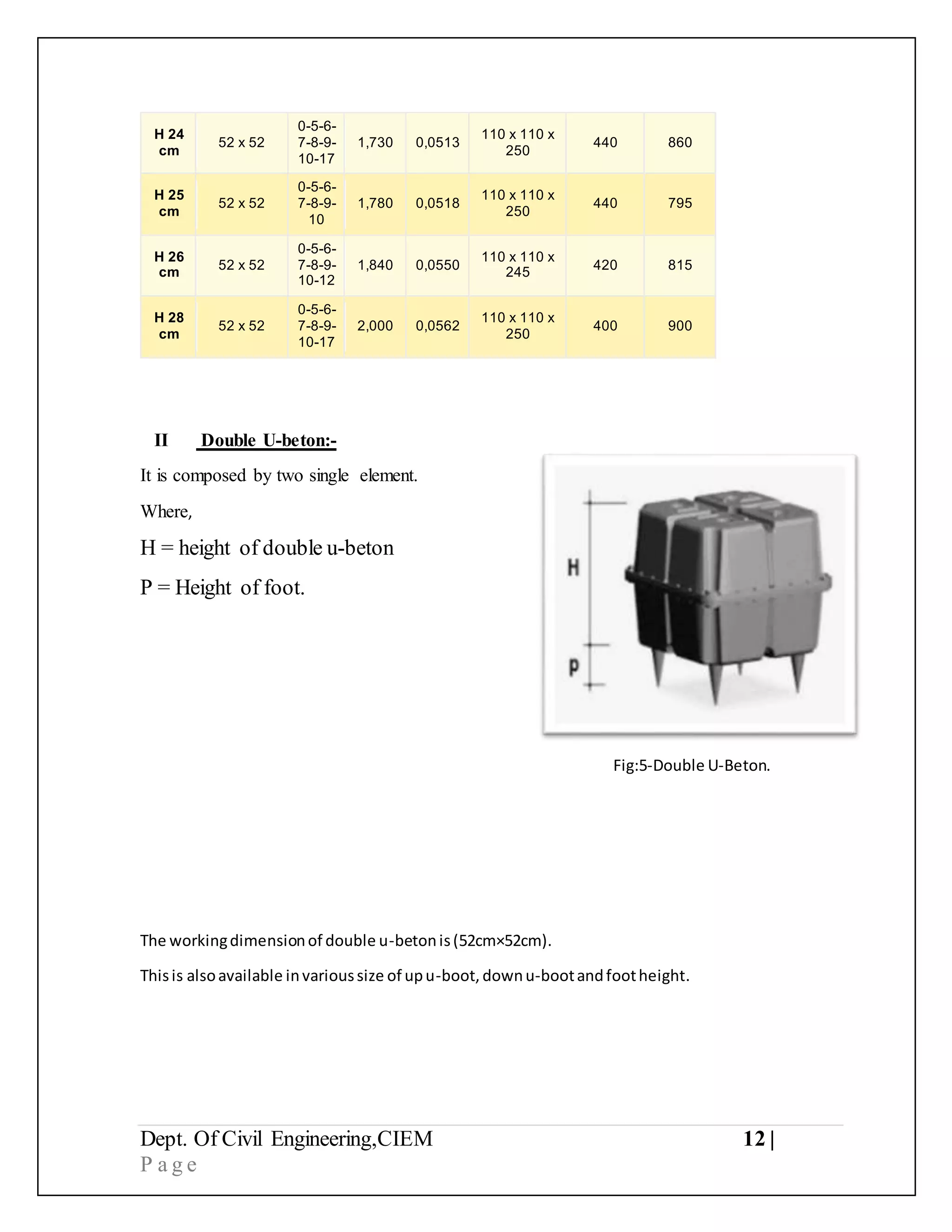

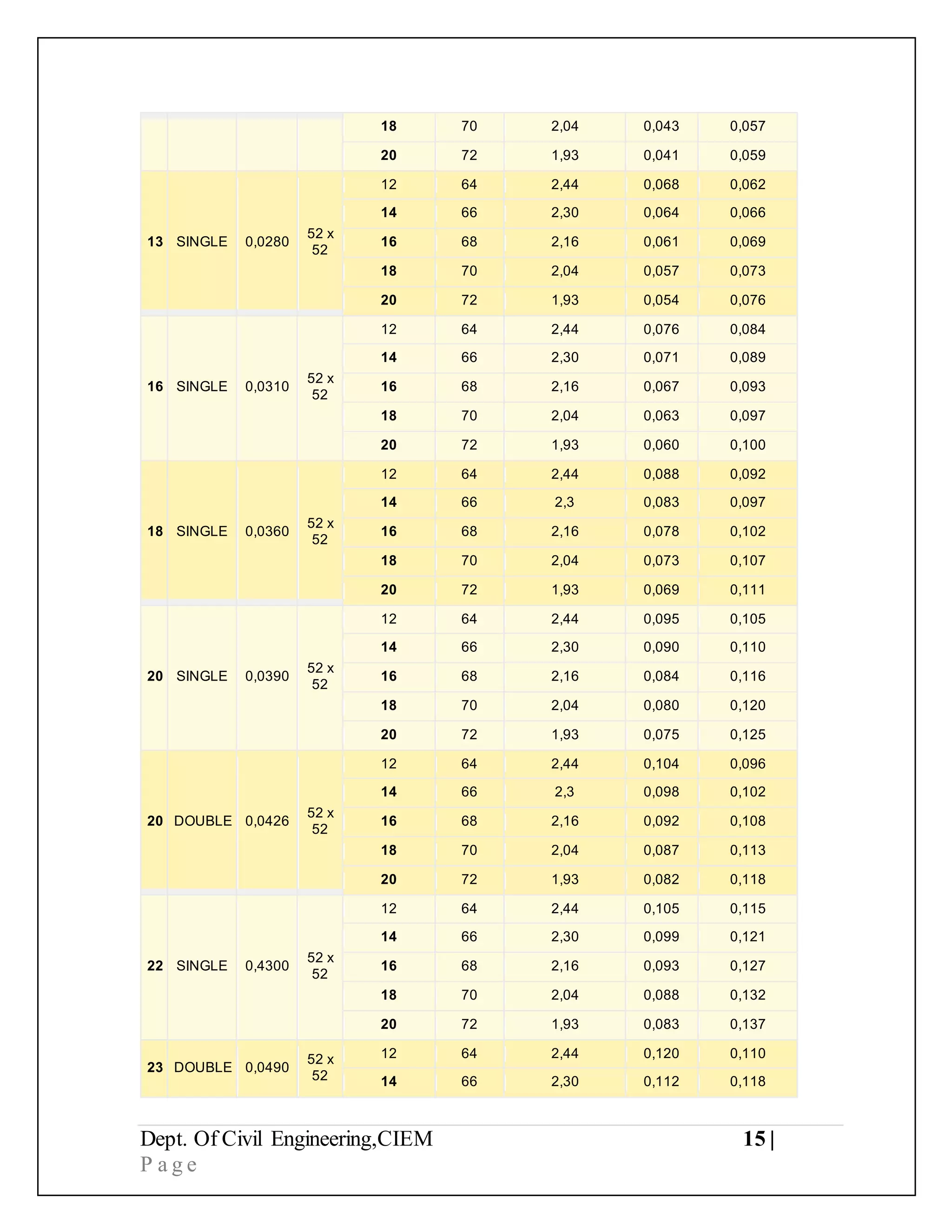

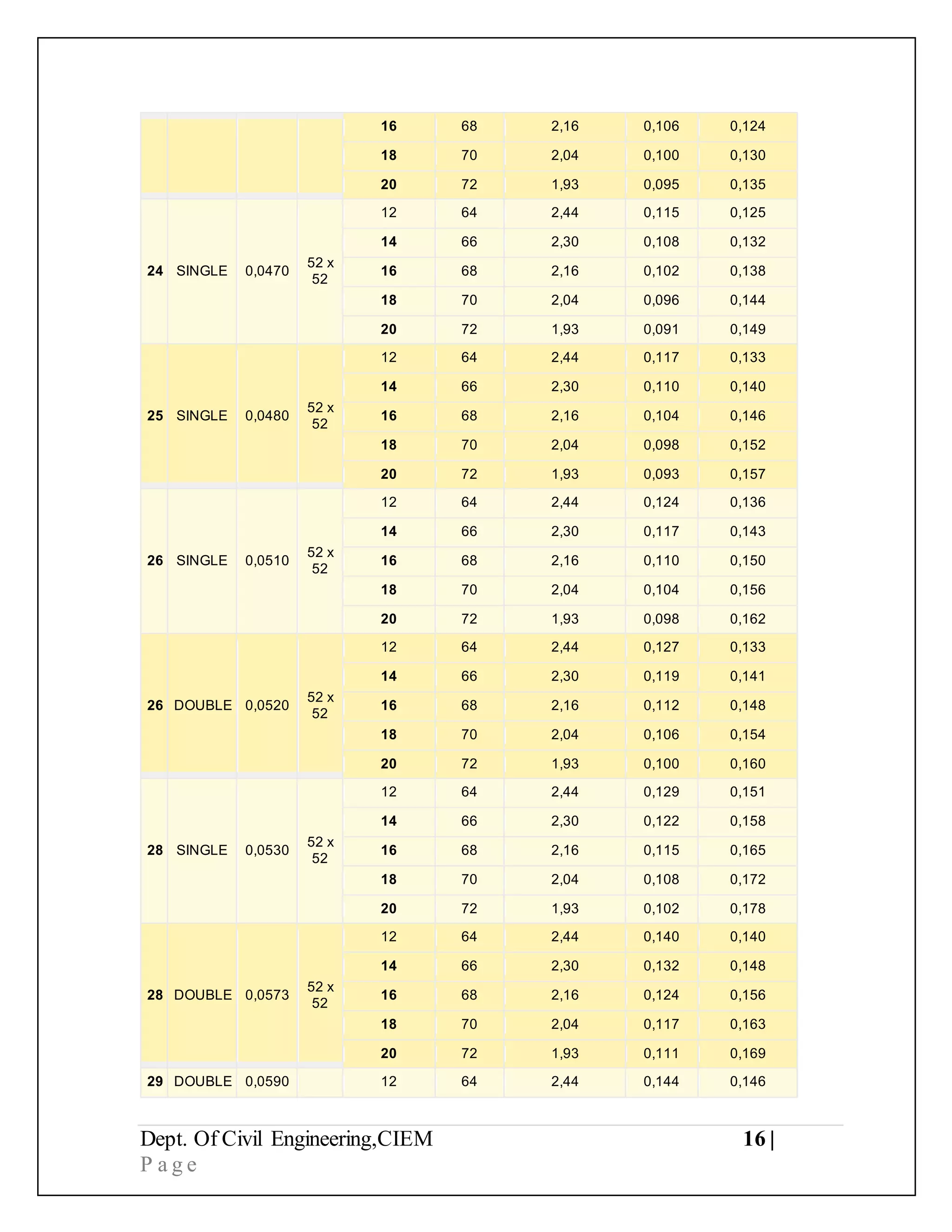

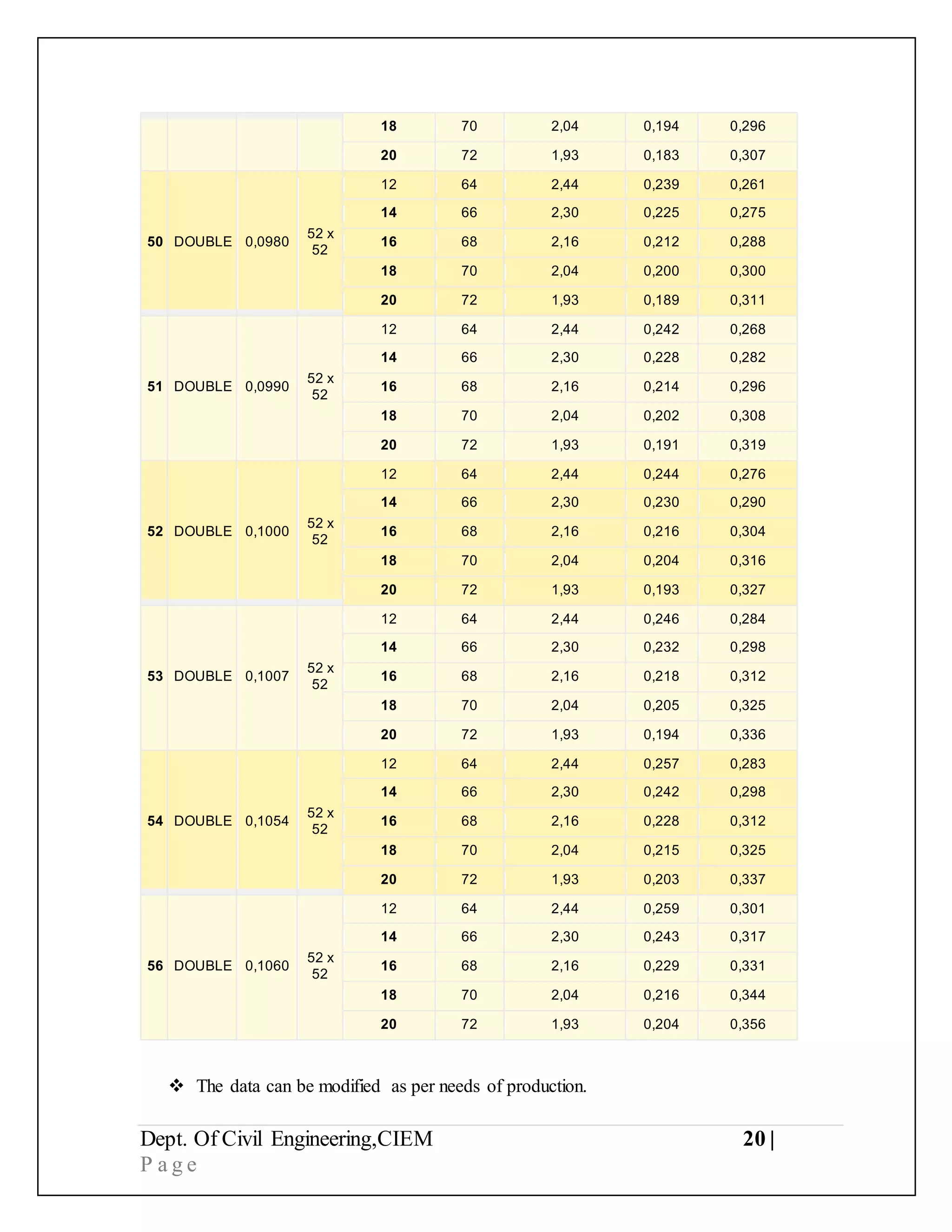

The document discusses U-Boot Beton technology, which is a recycled polypropylene formwork used to create two-way voided slabs and raft foundations. U-Boot Beton consists of interconnected U-shaped elements that are installed to form voids in concrete slabs, providing strength and reduced weight. The document describes the parts of U-Boot Beton including spacers, connection bridges, and closing plates used during installation. It also discusses single and double U-Boot Beton elements and provides tables of specifications for different sizes.

![Dept. Of Civil Engineering,CIEM 30 |

P a g e

REFERENCE

BubbleDeck.com

Martina Schnellenbach-Held,StefanEhmann,KarstenPfeffer:“BubbleDeck - New

Ways inConcrete Building”.Technische UniversitätDarmstadt,DACON Volume 13,

1998

Martina Schnellenbach-Held,KarstenPfeffer:“BubbleDeckDesignof BiaxialHollow

Slabs”.Technische UniversitätDarmstadt,DACON Volume 14,1999

BubbleDeckReportfromA+U ResearchInstitute /ProfessorKleinmann - the

EindhovenUniversityof Technology/the Netherlands,1999

BubbleDeckTestReportbyKoning&Bienfaitb.v./The Netherlands,1998

Reportof BubbleDeckfromTechnischeUniversitaetinCottbus

Reportfrom the EindhovenUniversityof Technology/the Netherlands:”Broad

comparisonof concrete floorsystems”.December1997

BubbleDeckReportfromTechnical Universityof Denmark,2003

Reportfrom AdviesbureauPeutz&Associesb.v.:”Comparisonof BubbleDeckvs.

Hollowcore”.Netherlands,1997

"Optimisingof Concrete Constructions"; - The EngineeringSchool inHorsens/

Denmark,2000

BubbleDeck.nl:CUR-aanbeveling86-01

Martina Schnellenbach-Held,HeikoDenk:“BubbleDeckTime-DependentBehaviour,

Local PunchingAdditional Experimental Tests”.Technische UniversitätDarmstadt,

DACON Volume 14,1999

Schnellenbach-Held,M.,Pfeffer,K.:“Tragverhaltenzweiachsiger

Hohlkörperdecken,Beton- undStahlbetonbau”96 [9],573-578 (2001)

Pfeffer,K.:“UntersuchungzumBiege-undDurchstanztragverhaltenvon

zweiachsigenHohlkörperdecken”.Fortschritt-Berichte VDI,VDI-Verlag,Düsseldorf

2002

"PunchingShearStrengthof BubbleDeck" - The Technical Universityof Denmark,

2002

BubbleDeckTestreportfromUniversityof DarmstadtbyMarkus Aldejohann,

Martina Schnellenbach-Held,2003

BubbleDeckReportfromAECConsultingEngineersLtd./ProfessorM.P.Nielsen -

The Technical Universityof Denmark,1993

BubbleDeck TestreportfromUniversityof DarmstadtbyMarkus Aldejohannand

Martina Schnellenbach-Held,2002

TNO-ReportonBubbleDeckforthe WeenaTower/Rotterdam/ the Netherlands,

1997

TNO-Reportfor230 mm BubbleDeck:”Fire-safe in120 minutes”the Netherlands,

1999

German TestCertificate NumberP-SAC02/IV-065accordingto DIN 4102-2

concerningBubbleDeck® slabs,2001](https://image.slidesharecdn.com/reportsheetonu-bootbeton-180420111216/75/Report-sheet-on-u-boot-beton-30-2048.jpg)