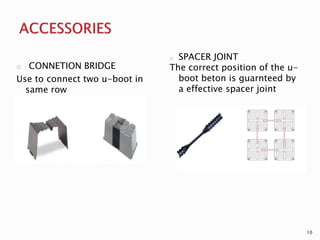

The document discusses U-boot formwork, which is a modular recycled plastic element used in reinforced concrete construction. U-boot reduces the amount of concrete needed and allows for larger spans without beams. It is available in various sizes and can be used to construct slabs, foundations, parking structures, and other building elements. The assembly process involves positioning reinforcing bars and U-boot shells, then casting concrete in phases. Key advantages are increased floor space, lighter structures, reduced material costs, and greater design flexibility. Several real-world examples employing U-boot formwork are provided.