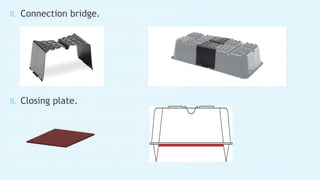

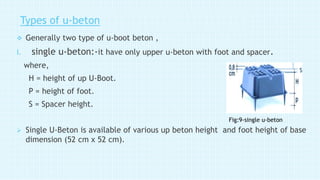

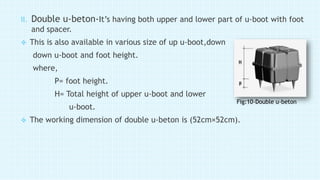

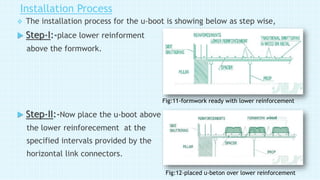

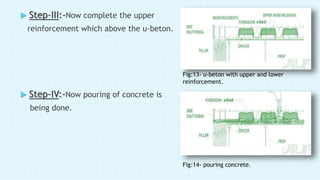

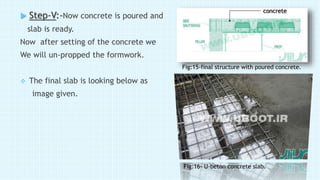

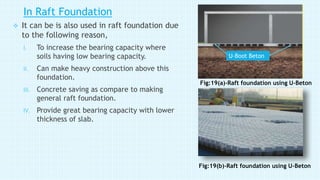

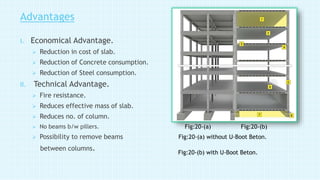

This presentation discusses U-Boot Beton technology, which uses recycled polypropylene formwork for construction. It allows for lighter and more economical building designs through large span slabs and foundations. The key components of U-Boot Beton include spacer joints, connection bridges, and closing plates. Installation involves placing reinforcement, then setting up the interconnected U-Boot formwork before pouring concrete. U-Boot Beton provides benefits like reduced material costs, increased seismic resistance, and more flexible architectural designs. It has various applications in buildings like hospitals, parking structures, and hotels.