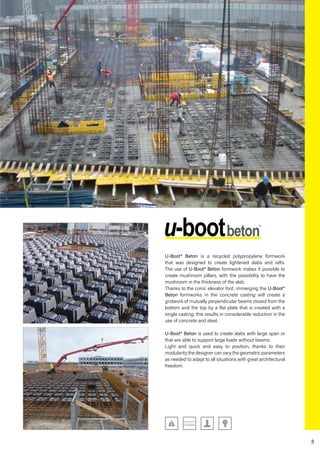

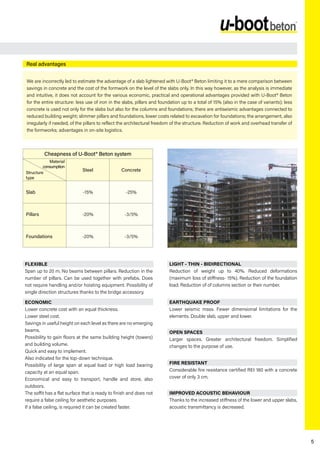

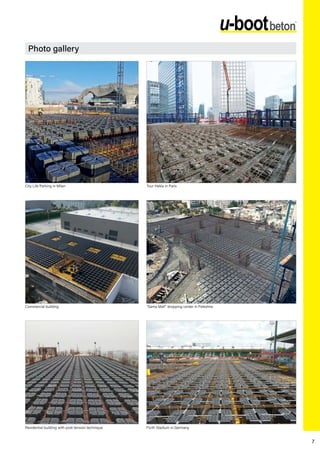

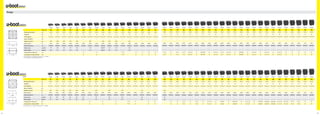

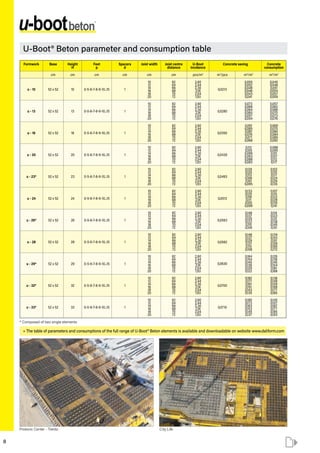

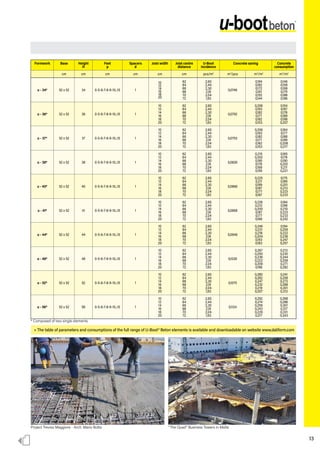

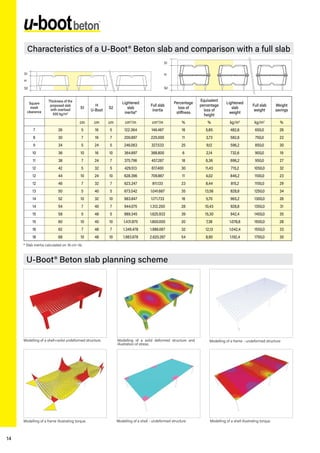

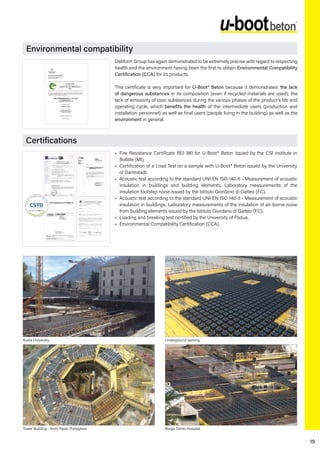

This document summarizes information about U-Boot® Beton, a recycled polypropylene formwork system used to create lightweight reinforced concrete slabs and rafts. It provides details on the product specifications, applications, advantages, and installation photos. The formwork allows creating voided slab structures that reduce concrete and steel usage, provide large spans, and increase architectural freedom. Benefits include lighter structures, cost savings, improved acoustics and seismic performance, and easier construction.