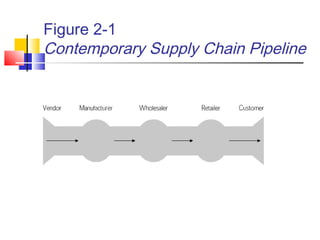

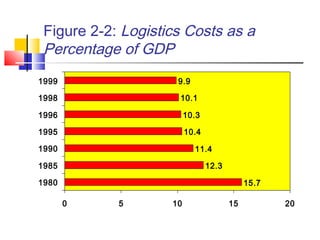

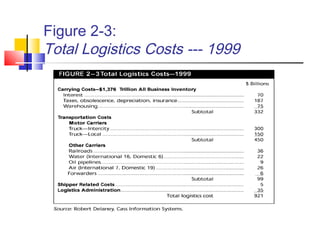

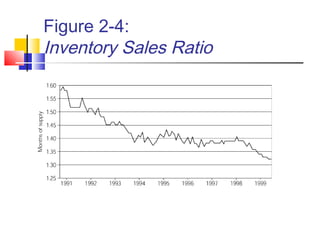

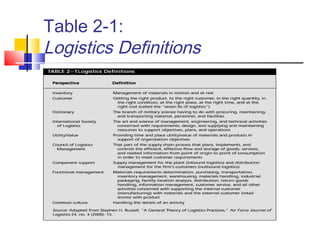

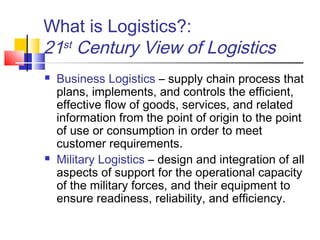

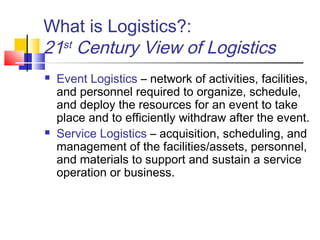

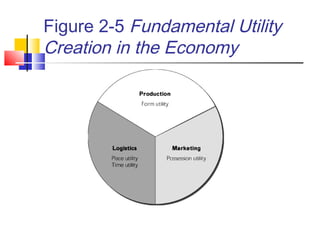

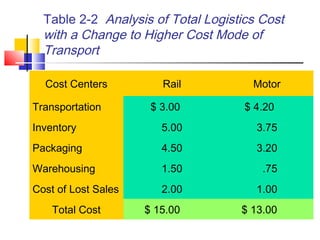

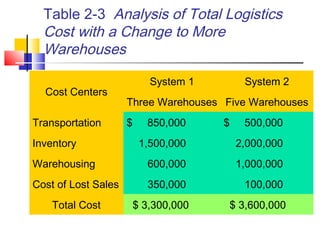

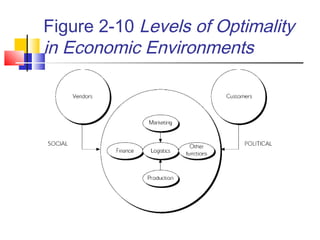

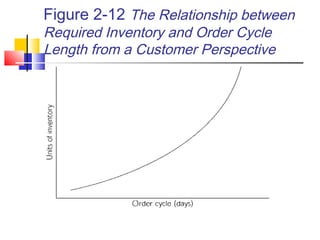

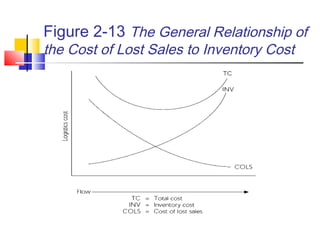

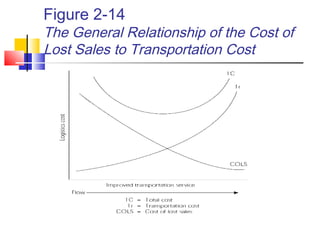

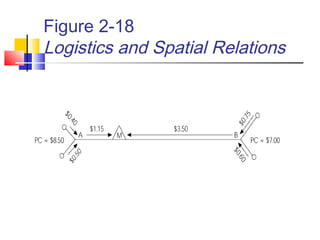

This chapter discusses the key dimensions and perspectives of logistics systems. It explains how logistics has evolved from focusing on physical distribution and materials management to integrated supply chain management. The chapter outlines how effective logistics contributes to economic efficiency on a macro level and interfaces between other business functions like marketing and manufacturing on a micro level. It also analyzes different approaches to evaluating logistics systems and factors that influence logistics costs.