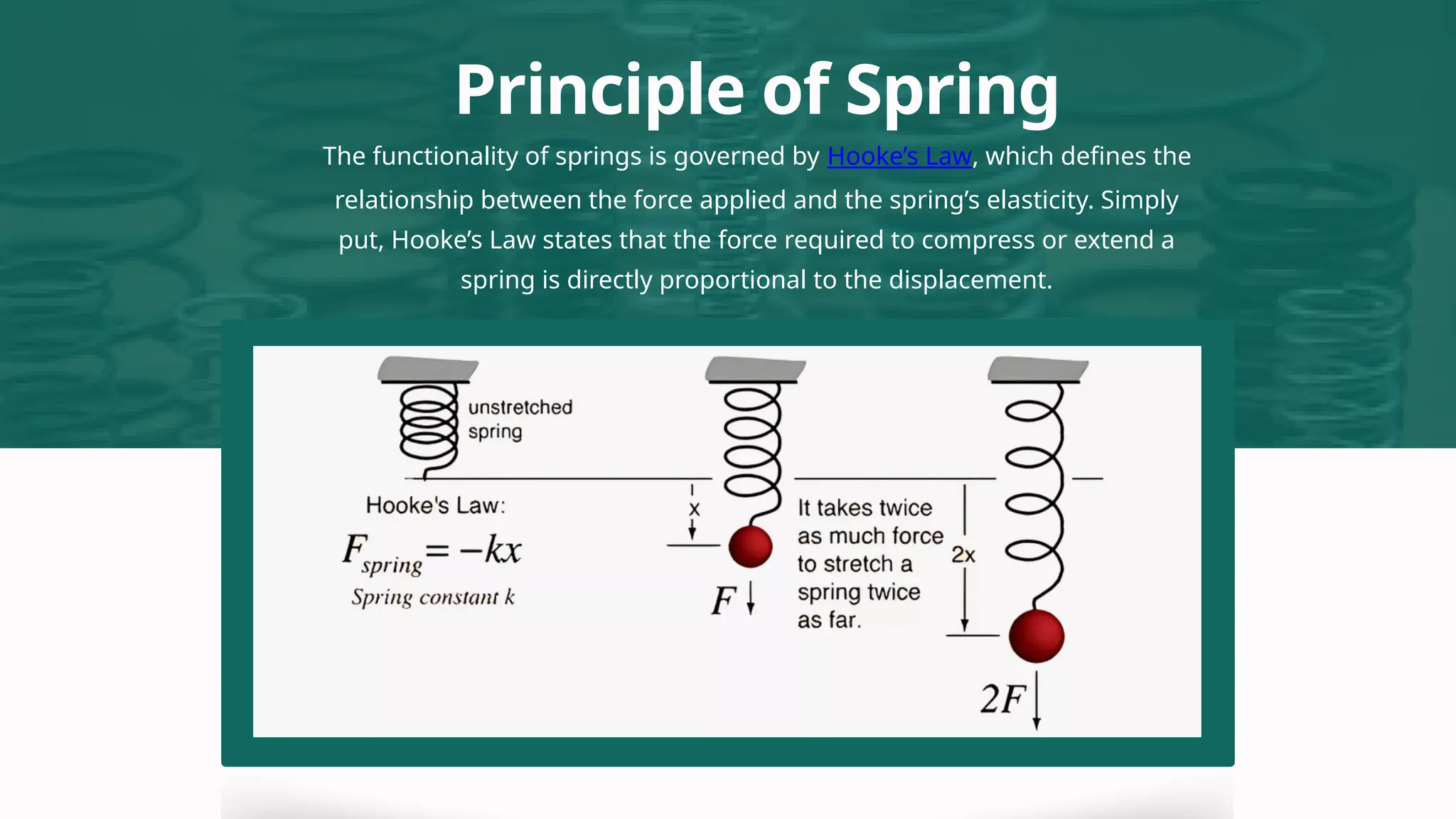

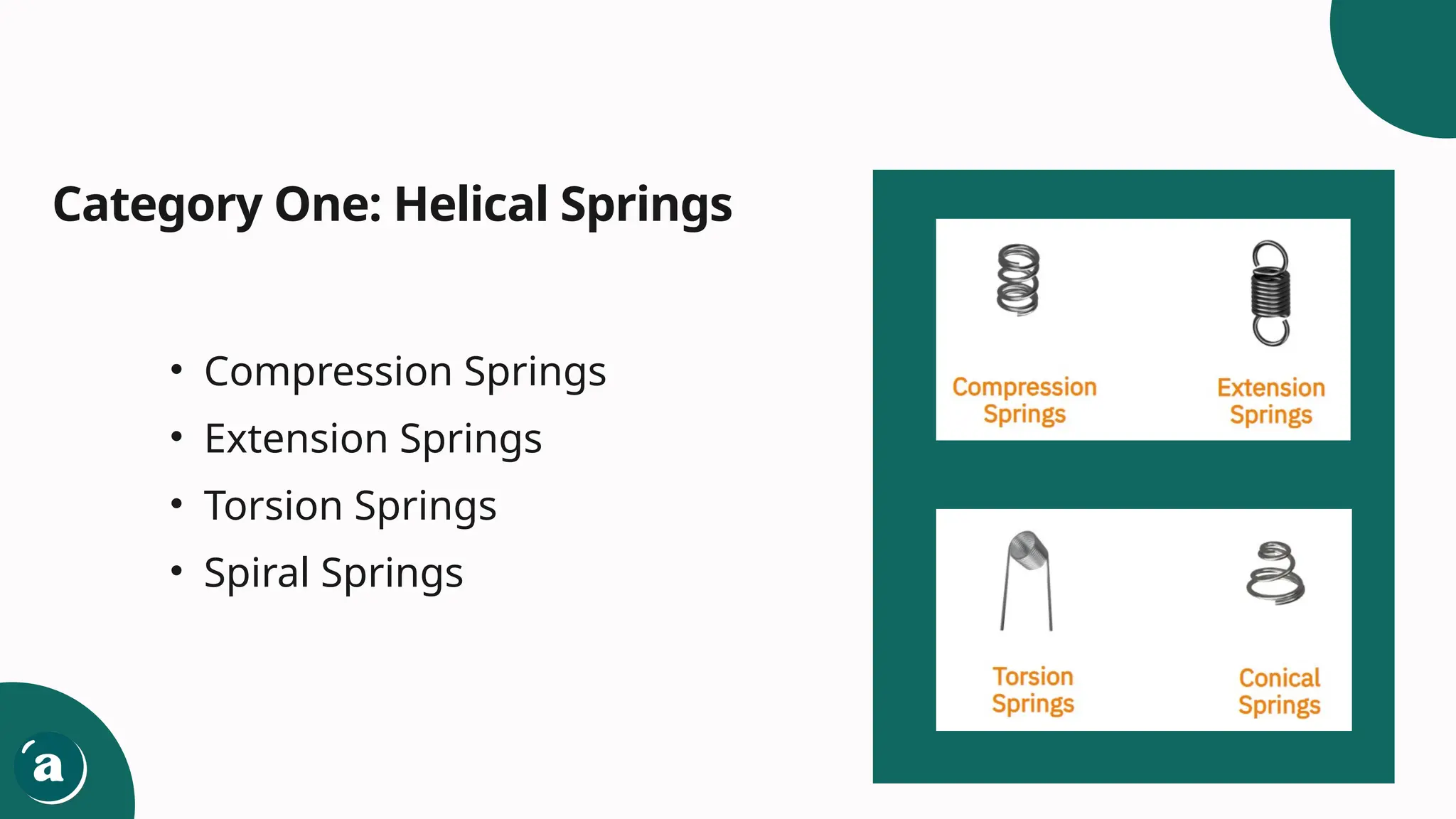

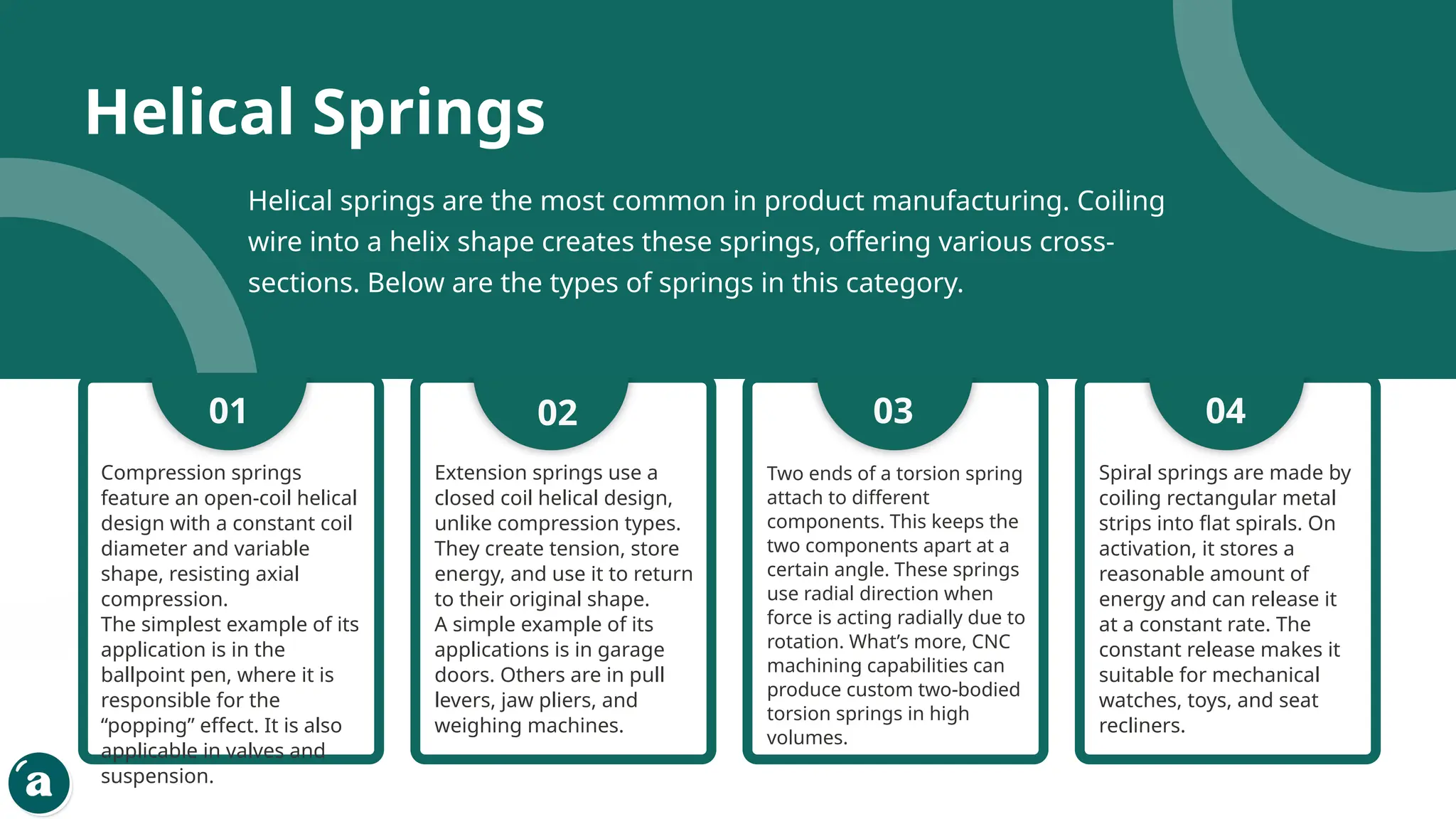

The document provides an overview of different types of springs, including helical, leaf, and disk springs, detailing their definitions, principles, designs, and applications. It highlights how springs function according to Hooke's law, storing and exerting mechanical energy in various mechanisms. Additionally, it discusses the use of springs in manufacturing and their role in enhancing functionality in mechanical designs.