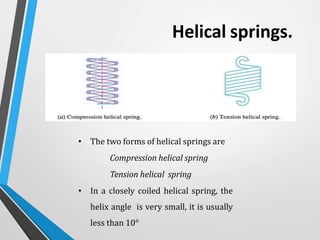

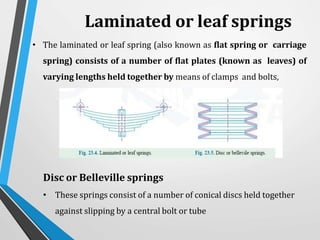

This document discusses different types of springs, their applications, and key terms used in compression springs. It provides information on five main types of springs: helical, conical and volute, torsion, laminated or leaf, and disc or Belleville springs. Helical springs are the most common and can be used for both compression and tension. Springs are widely used to cushion impacts, apply forces, control motion, and store energy in various mechanical applications. Key terms discussed include solid length, free length, spring index, spring rate, and pitch.