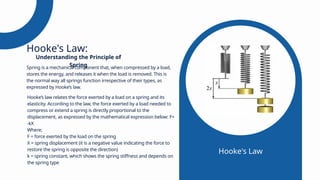

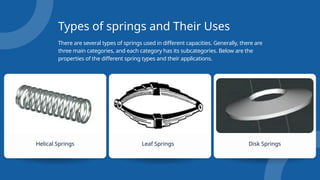

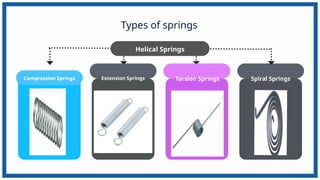

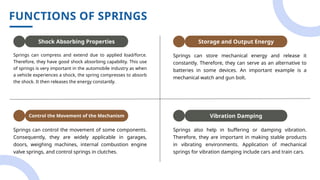

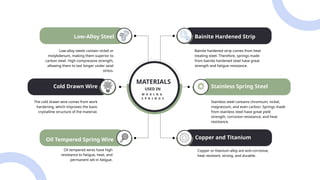

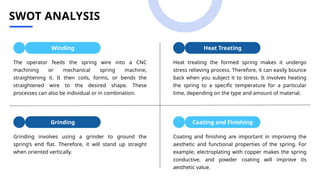

The document provides an overview of different types of springs, including helical, leaf, disk, and their uses, along with their manufacturing processes and material properties. It explains key principles such as Hooke's law, functions of springs, and the significance of selecting the right type for various applications. Additionally, it covers common manufacturing processes involved in spring production and offers insights into the materials used.