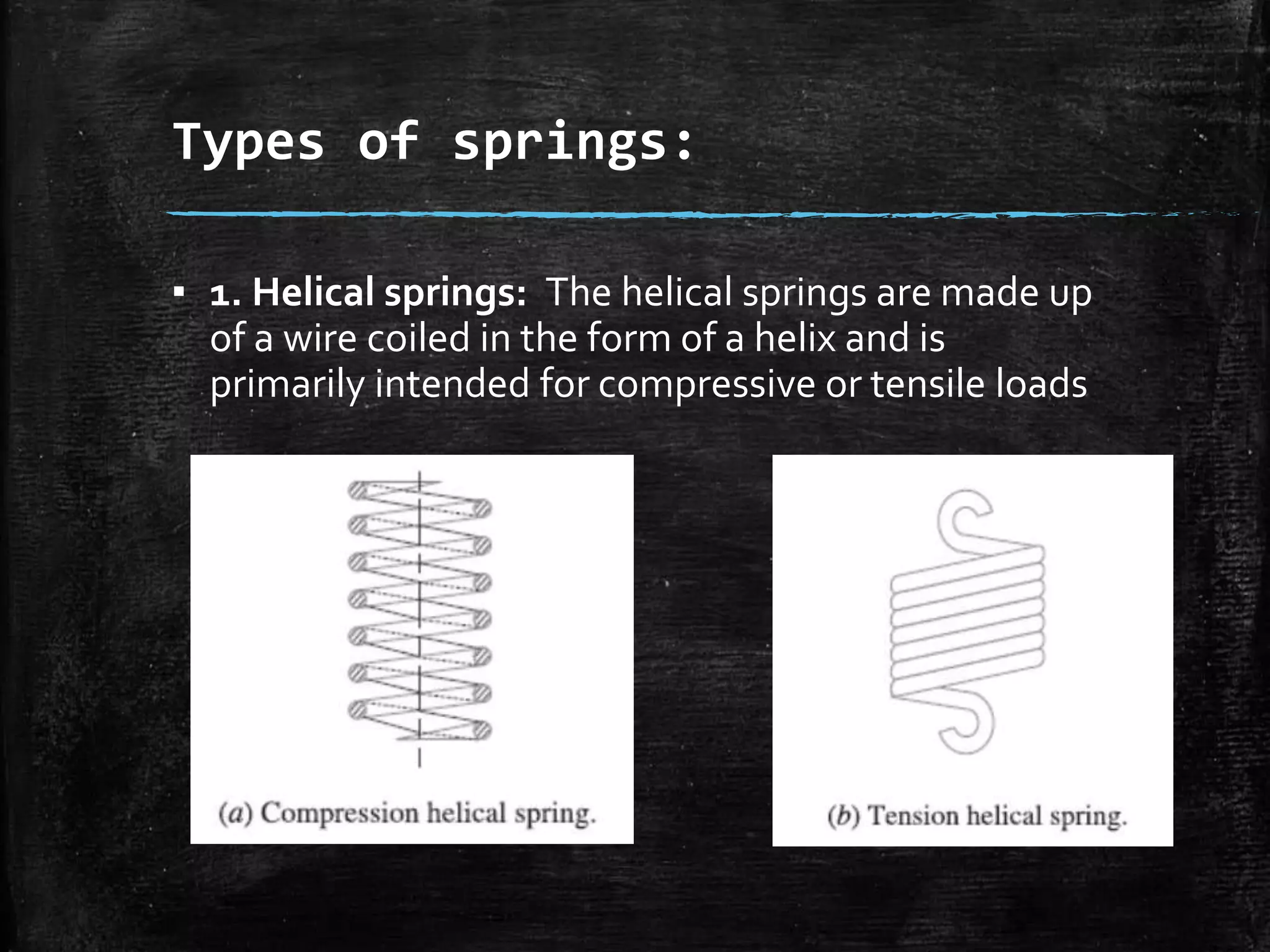

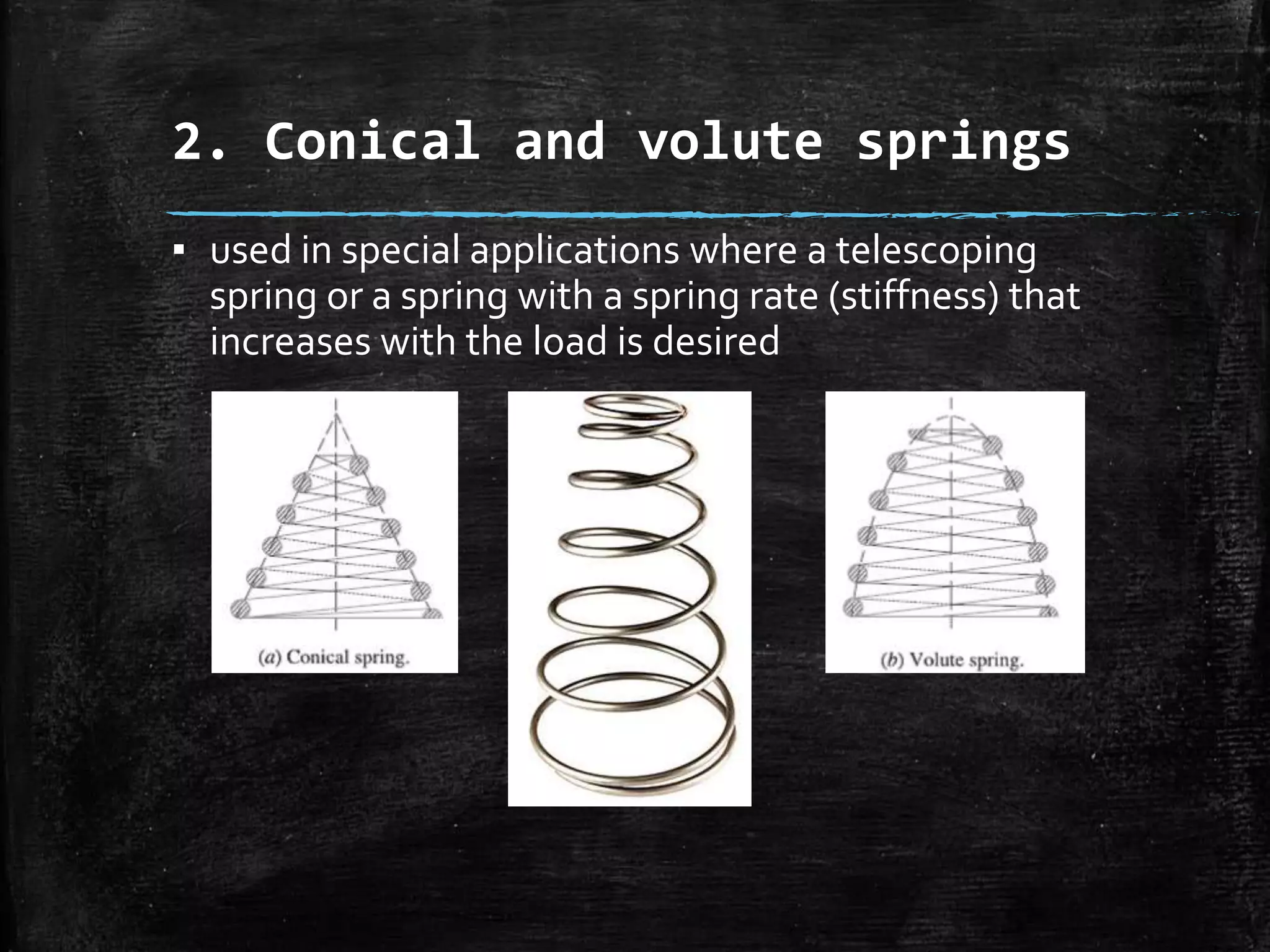

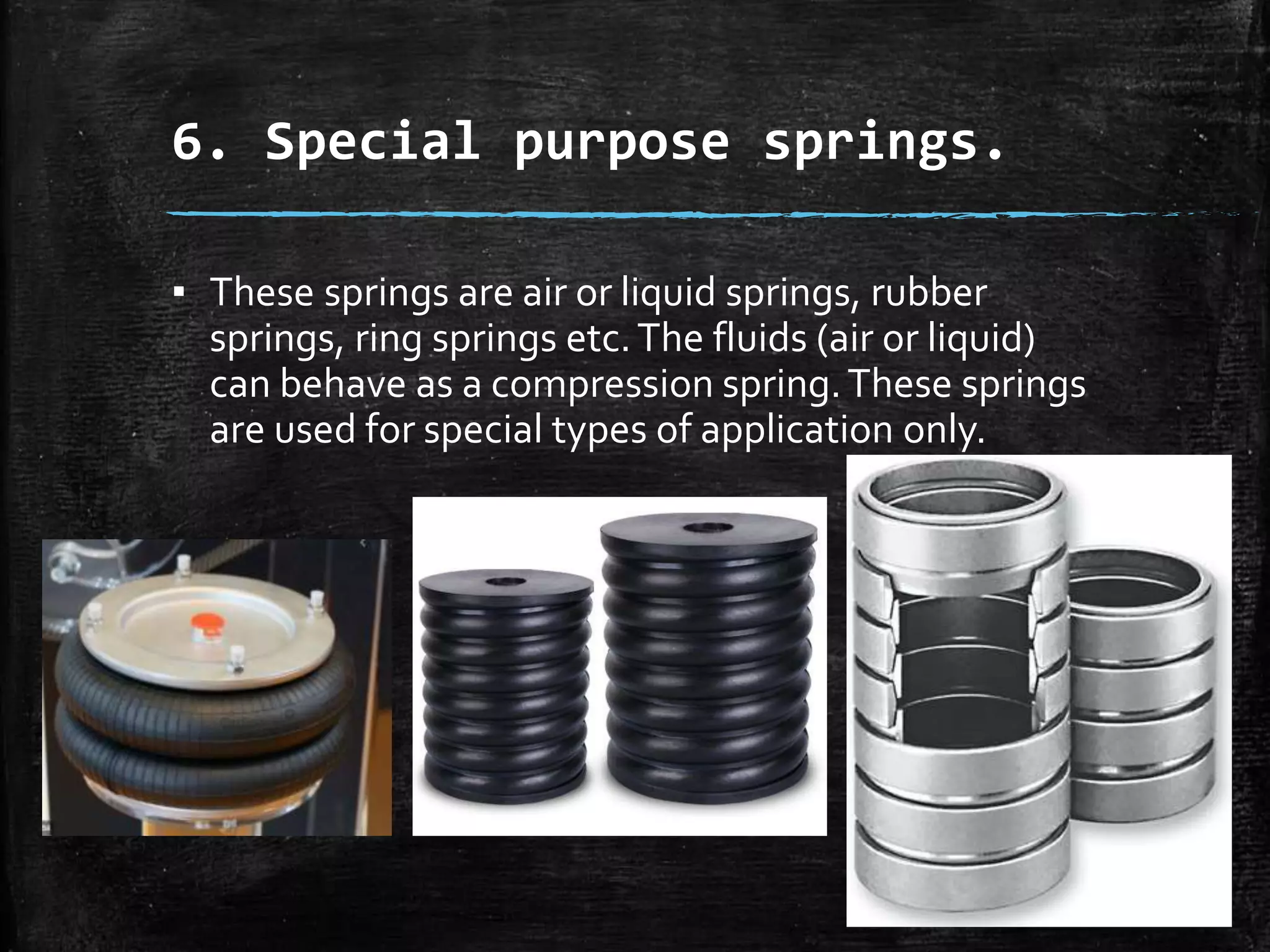

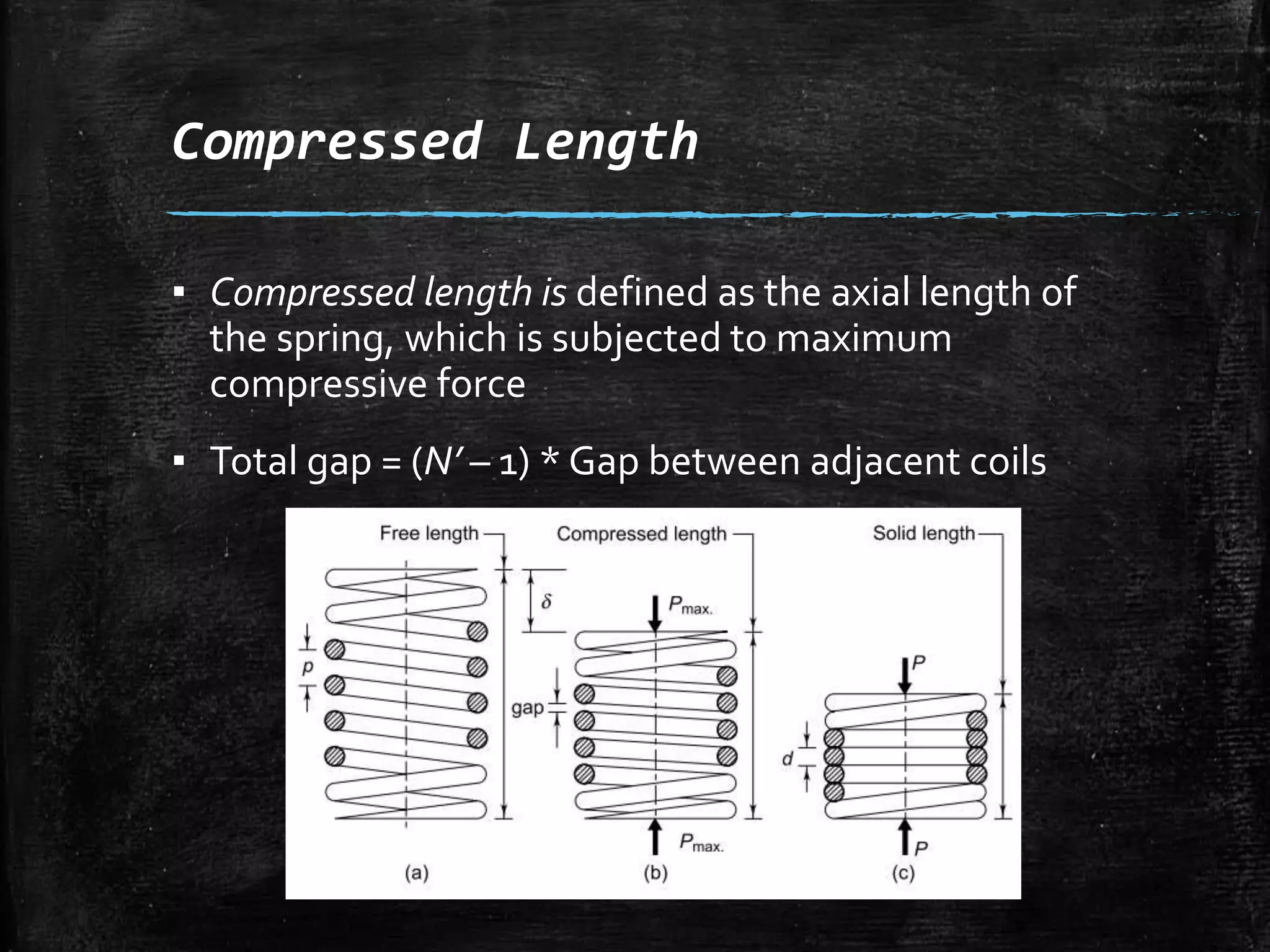

The document discusses different types of mechanical springs, including helical, conical, volute, torsion, laminated/leaf, and special purpose springs. It defines key terms used in compression springs such as solid length, free length, compressed length, spring index, spring rate, and pitch. The introduction outlines common applications of springs such as cushioning shock/vibration, applying forces, controlling motion, and storing energy. Types of springs are described along with diagrams of volute and helical torsion springs. Formulas are provided for solid length, free length, spring index, and spring rate. References for further reading on the topic are listed at the end.