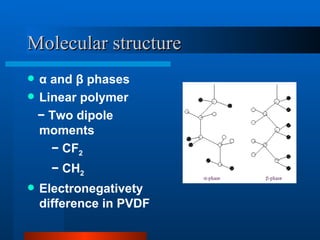

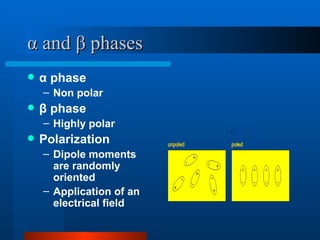

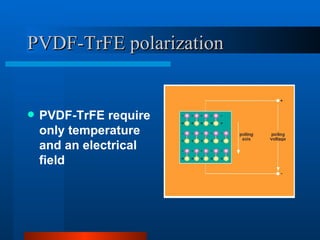

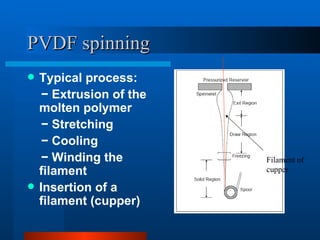

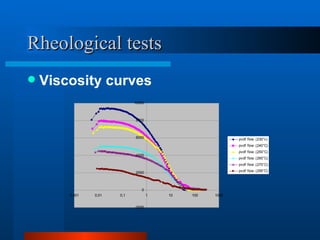

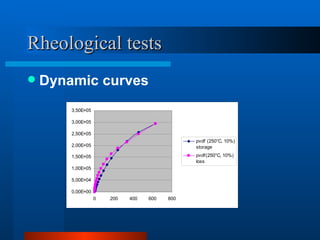

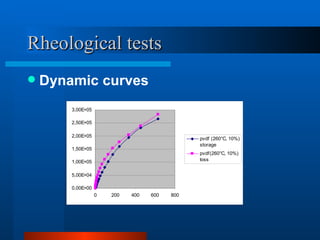

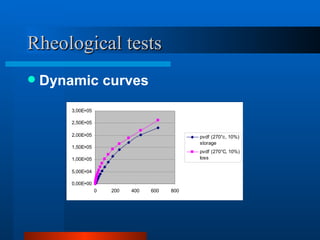

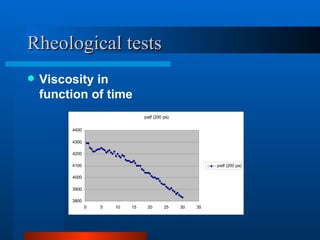

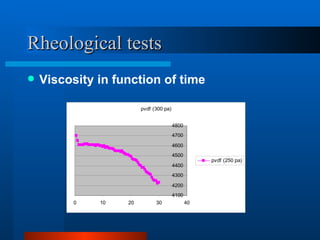

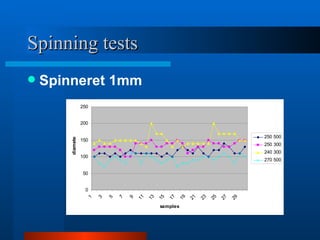

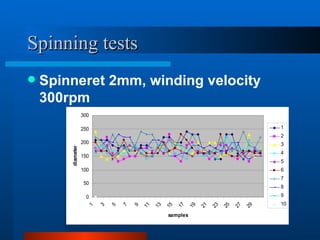

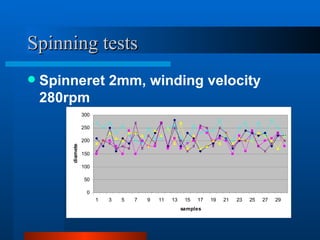

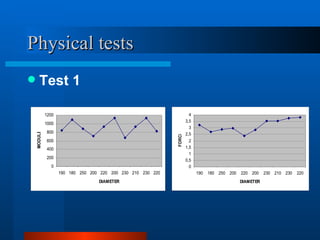

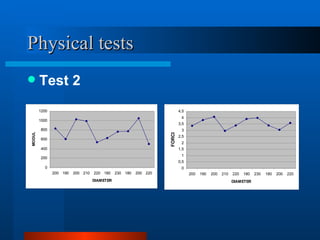

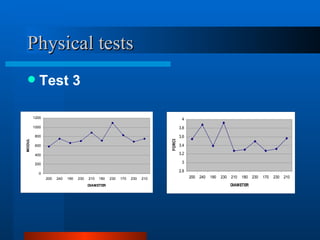

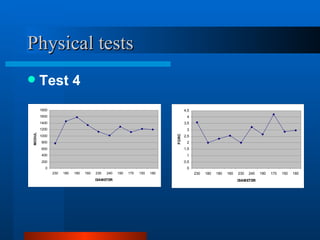

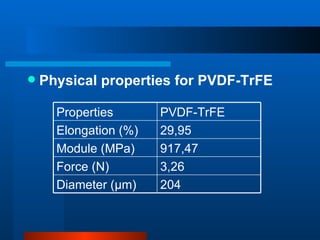

This document summarizes the development of a sensor based on polyvinylidene fluoride (PVDF). It discusses the objectives to develop the sensor and spin a PVDF filament with a diameter of 200μm. It describes the piezoelectric properties of PVDF and its molecular structure. Rheological tests were conducted to analyze viscosity and dynamic properties of PVDF at different temperatures. Spinning tests produced a filament diameter of 200μm but with variations. Physical tests on the filament showed good elongation and modulus. The development of the PVDF-based sensor was achieved.