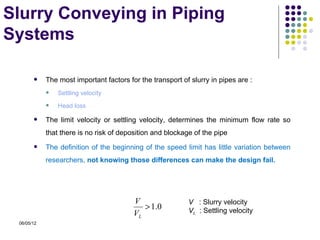

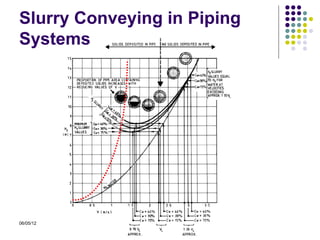

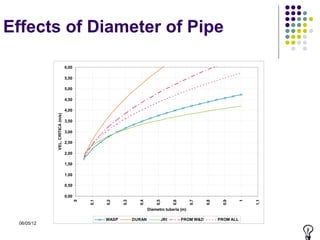

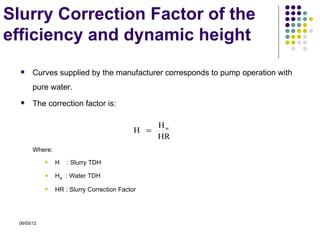

This document discusses slurry conveying systems used in mining applications to transport mining waste and concentrates. It covers Newtonian slurries characterized by small particle sizes and low concentrations. Key aspects summarized include rheological models for viscosity, methods for calculating settling velocity, and steps to design a slurry transport system, including characterizing flows, determining pipe diameter, head losses, and pump selection. Slurry transport is affected by particle size, concentration, and pipe diameter, with minimum flow rates defined by settling velocity limits.

![Settling Velocity Models

.

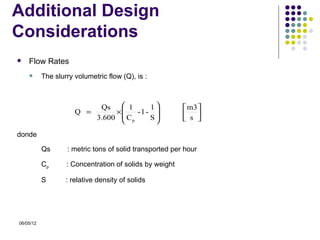

Durand - Condolios

Durand

VC = FL 2 gD( S − 1)

Durand modified by Juan Rayo

VC = 1.25 ⋅ FL [ 2 gD( S − 1) ]

0.25

Mc Elvain - Cave

Wasp

1

d 50 6

VC = 3.116C 0.186

V 2 gD( S − 1)

D

06/05/12](https://image.slidesharecdn.com/slurry-conveying-en-120505201754-phpapp02/85/Slurry-conveying-13-320.jpg)

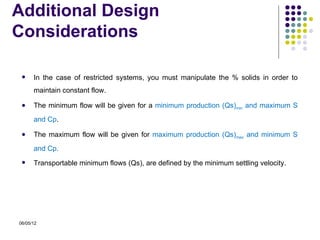

![Slurry correction Factor HR

McElvain & Cave model for HR

K × Cv

HR = 1 -

20

where:

K S

K = K ( S, d 50 ) 0.50 8.00

0.45 5.00

4.00

0.40

3.00

0.35 2.55

0.30

2.00

0.25

1.80

0.20

0.15 1.25

0.10

1.10

0.05

0.00

0.01 0.1 1.0 10.0

06/05/12

D50 [mm]](https://image.slidesharecdn.com/slurry-conveying-en-120505201754-phpapp02/85/Slurry-conveying-19-320.jpg)

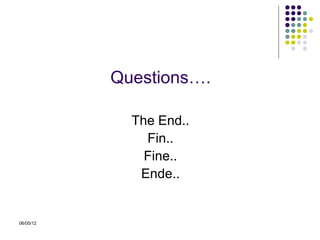

![Cerda Model for HR & FL

Limite settling velocity factor (FL)

[ ] [

Fl = 1.4Cv0.045 + ( 0.18 + 0.006 ln ( Cv ) ) ln ( d 50 ) * 0.042d 50 − 0.218d 50 + 0.265d 50 + .96

3 2

]

Slurry correction factor HR & ER

HR = a( c ln( d 50 ) + d ) + 1

where :

a = −0.1605C p + .000466

ρs

b=

ρl

c = 0.0133b 3 − 0.1785b 2 + 1.0555b − 0.8232

d = .04630b 3 − 0.6361b 2 + 3.8714b − 2.9632

06/05/12](https://image.slidesharecdn.com/slurry-conveying-en-120505201754-phpapp02/85/Slurry-conveying-22-320.jpg)