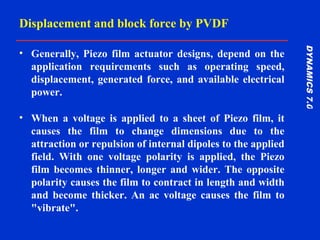

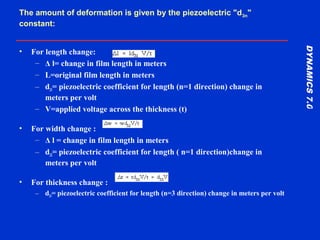

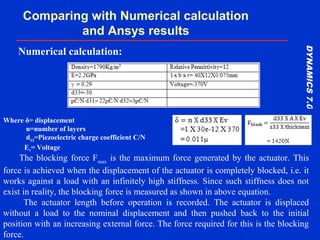

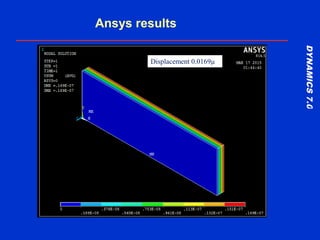

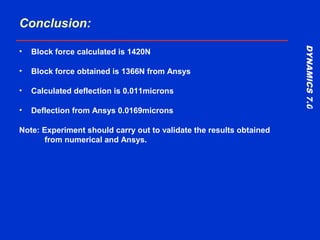

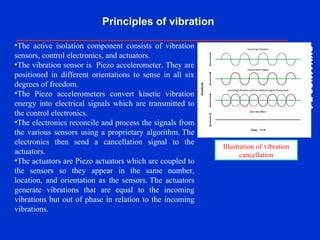

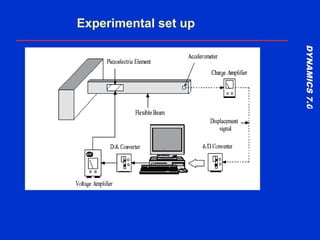

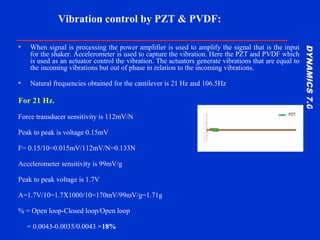

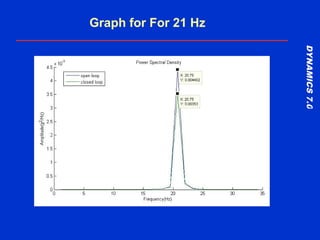

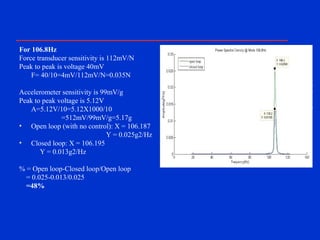

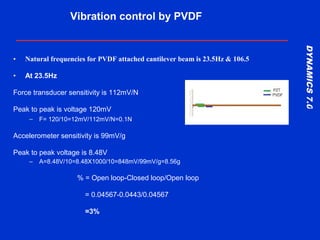

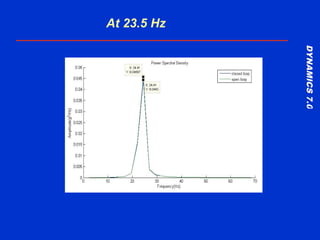

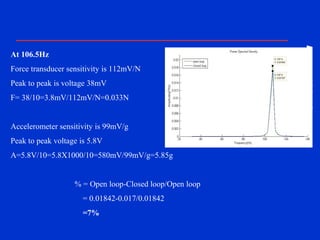

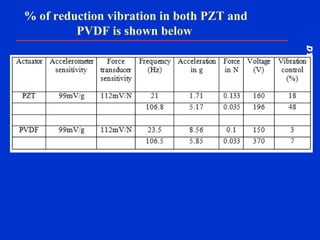

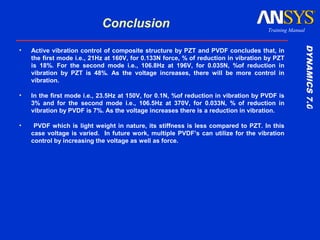

The document discusses the dynamics of PVDF (Polyvinylidene fluoride) as an actuator, detailing its deformation under electrical voltage and the calculation of blocking force. It also covers active vibration control systems, their components, and experimental setups to measure vibration response in cantilever beams using piezo accelerometers and actuators, concluding with comparative effectiveness of PVDF and PZT (lead zirconate titanate) materials in reducing vibration at various frequencies. Results indicate that while PZT exhibits greater vibration reduction, PVDF’s lower weight and future potential use in multiple layers are noted.