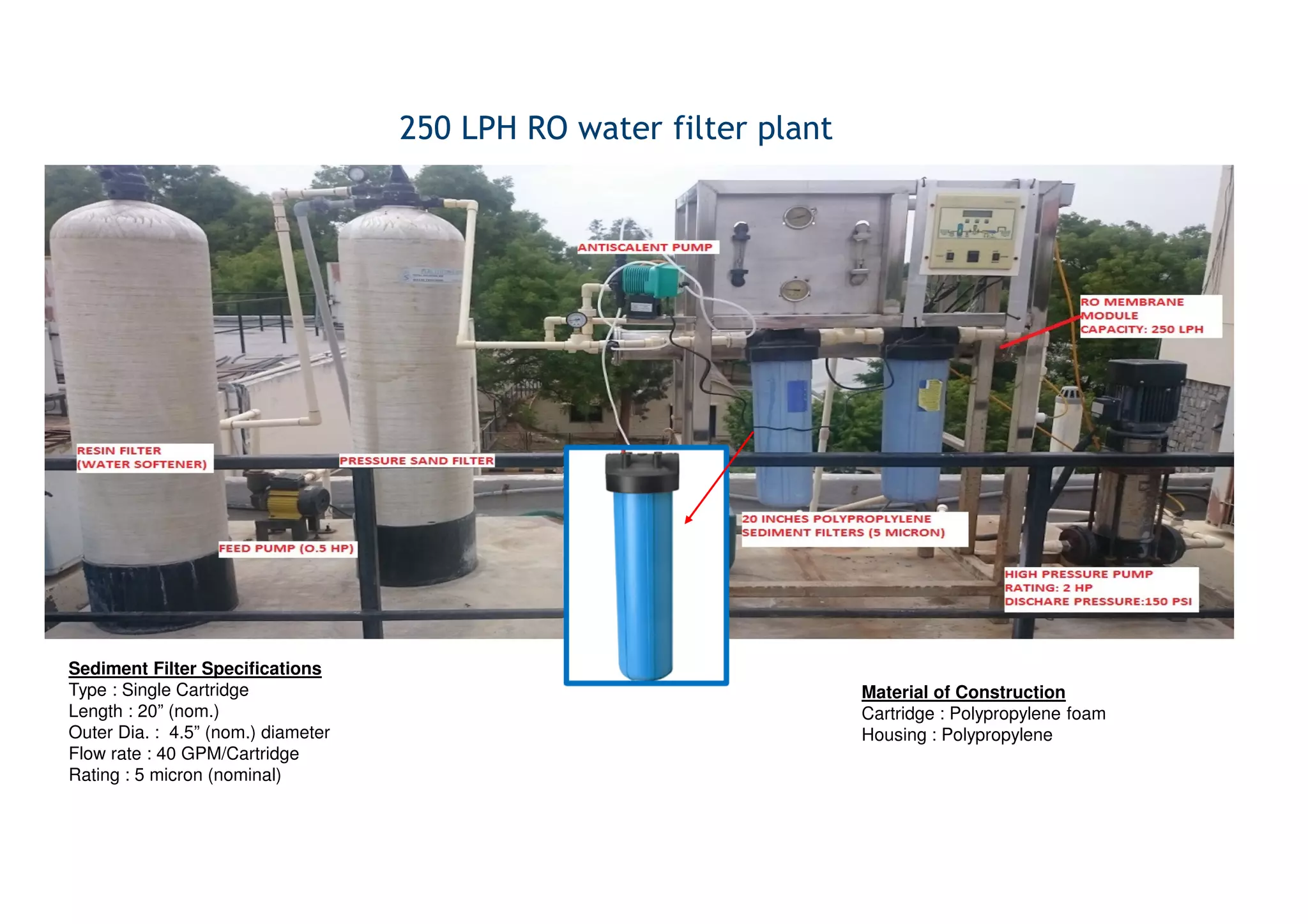

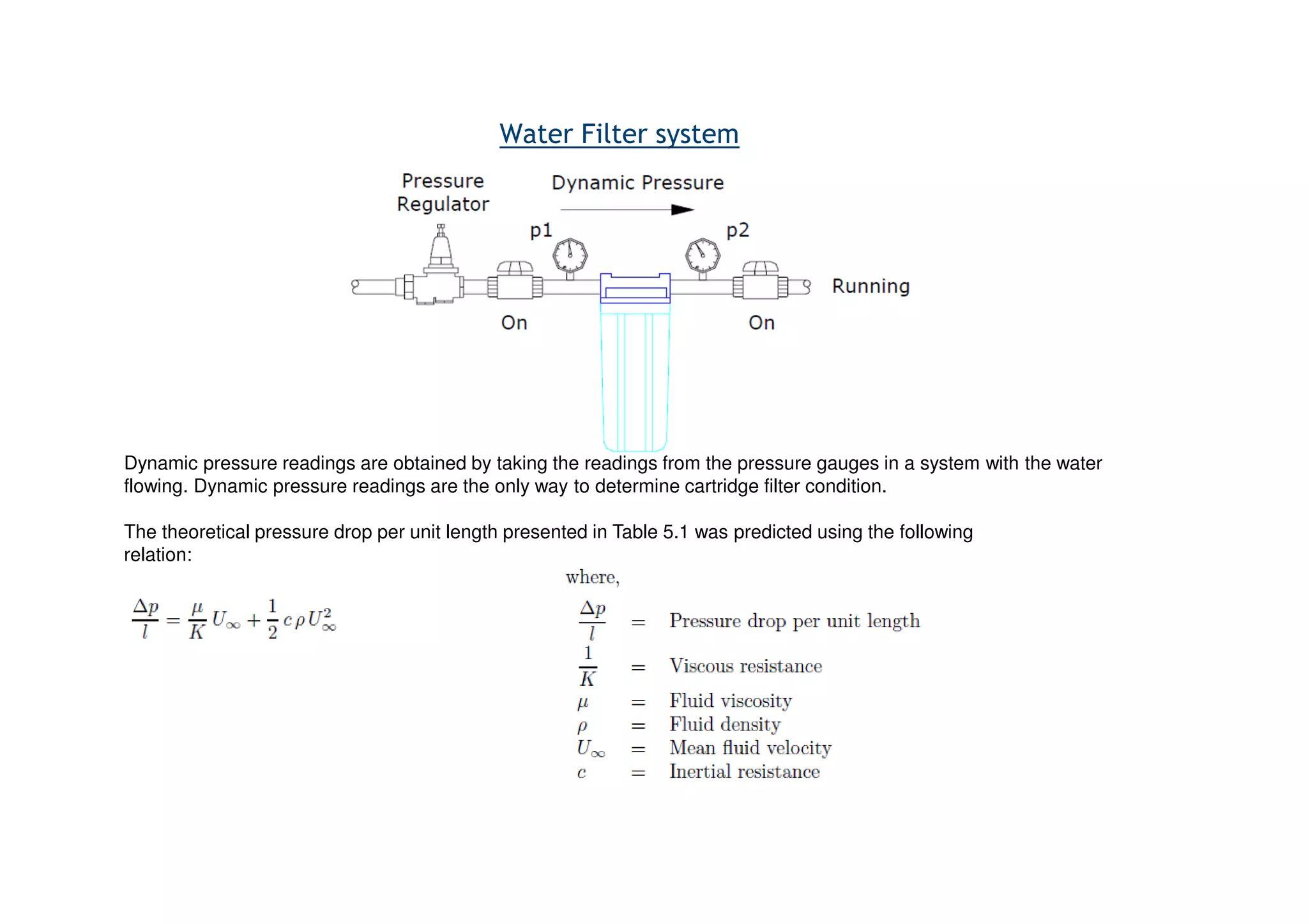

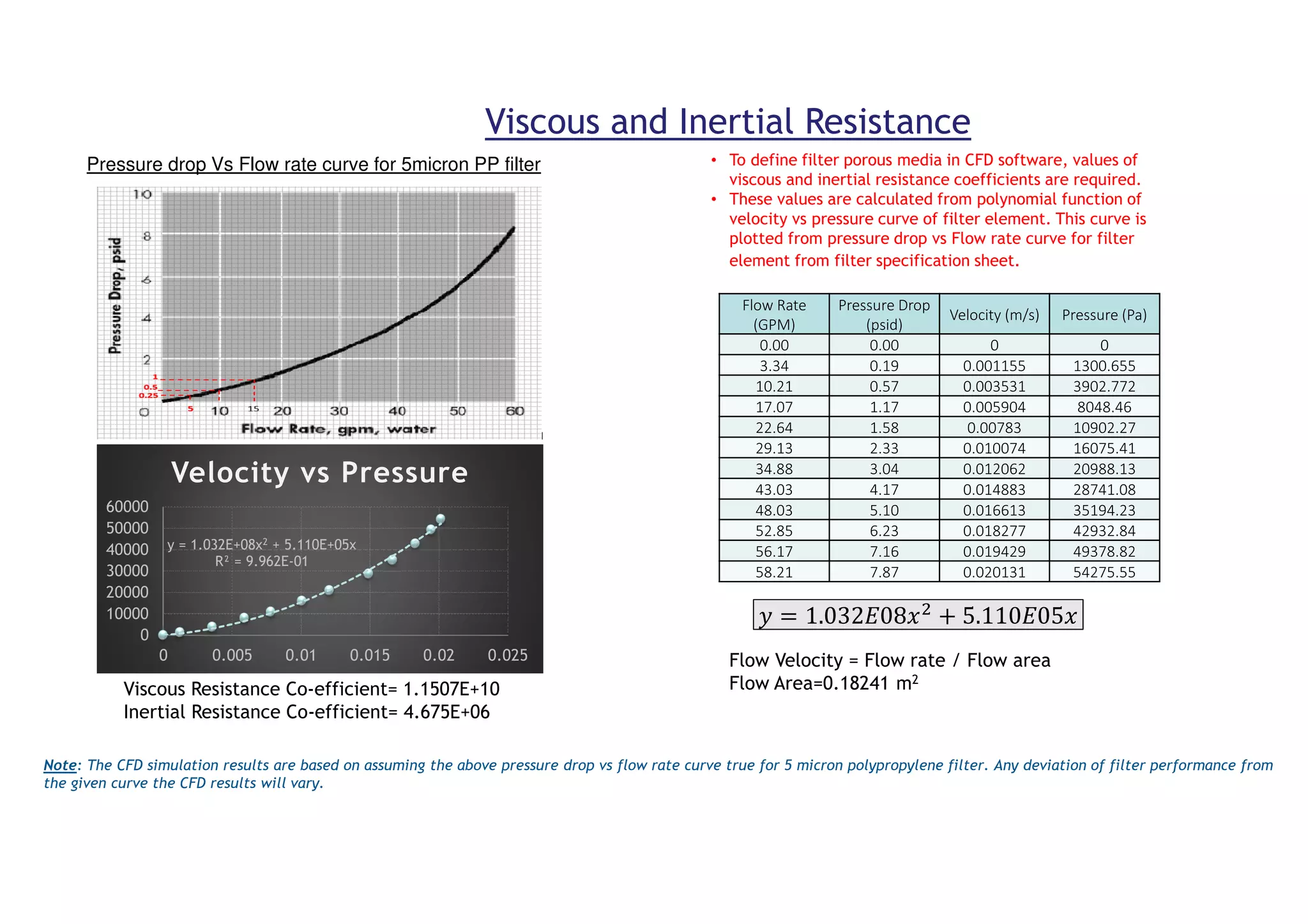

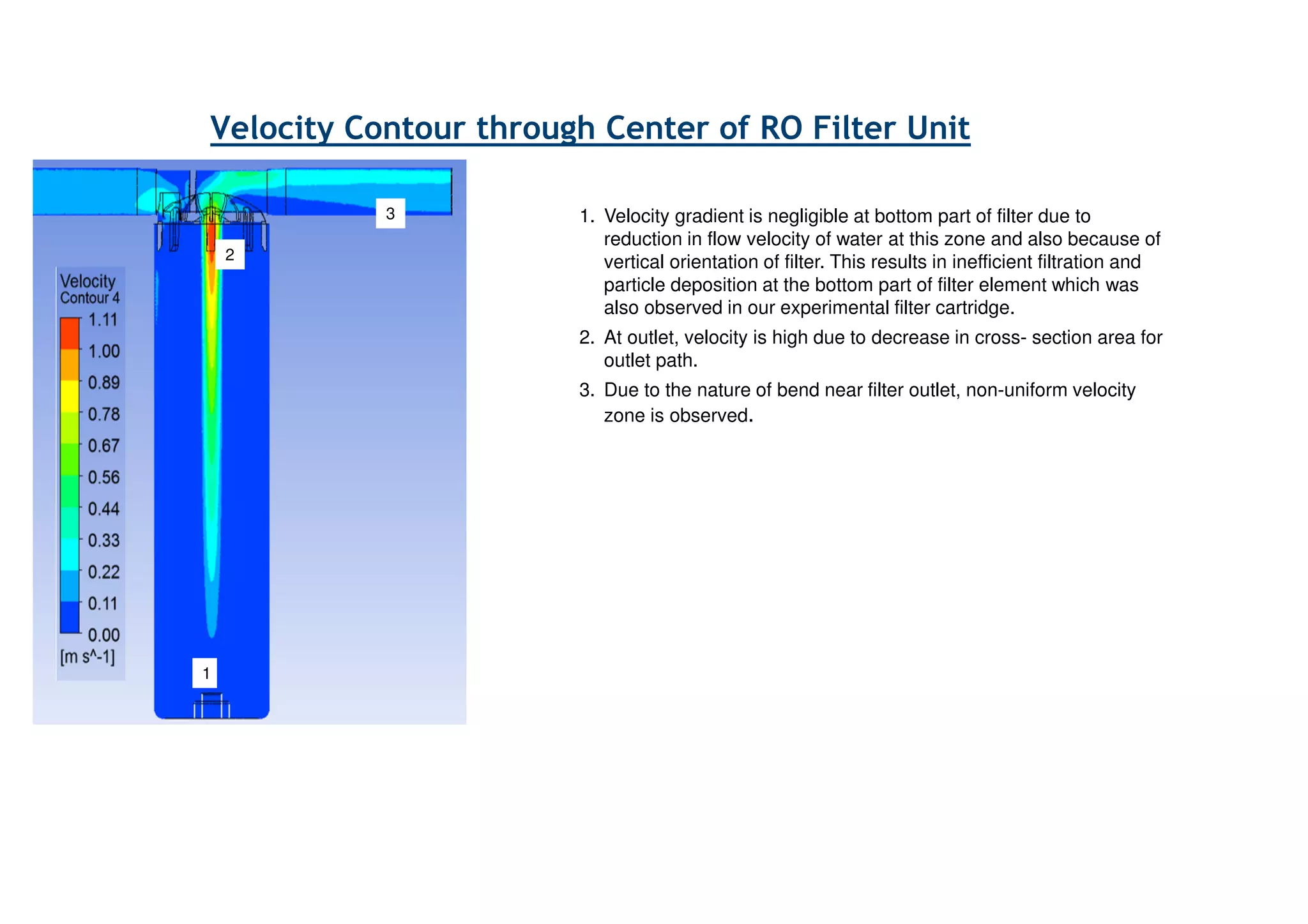

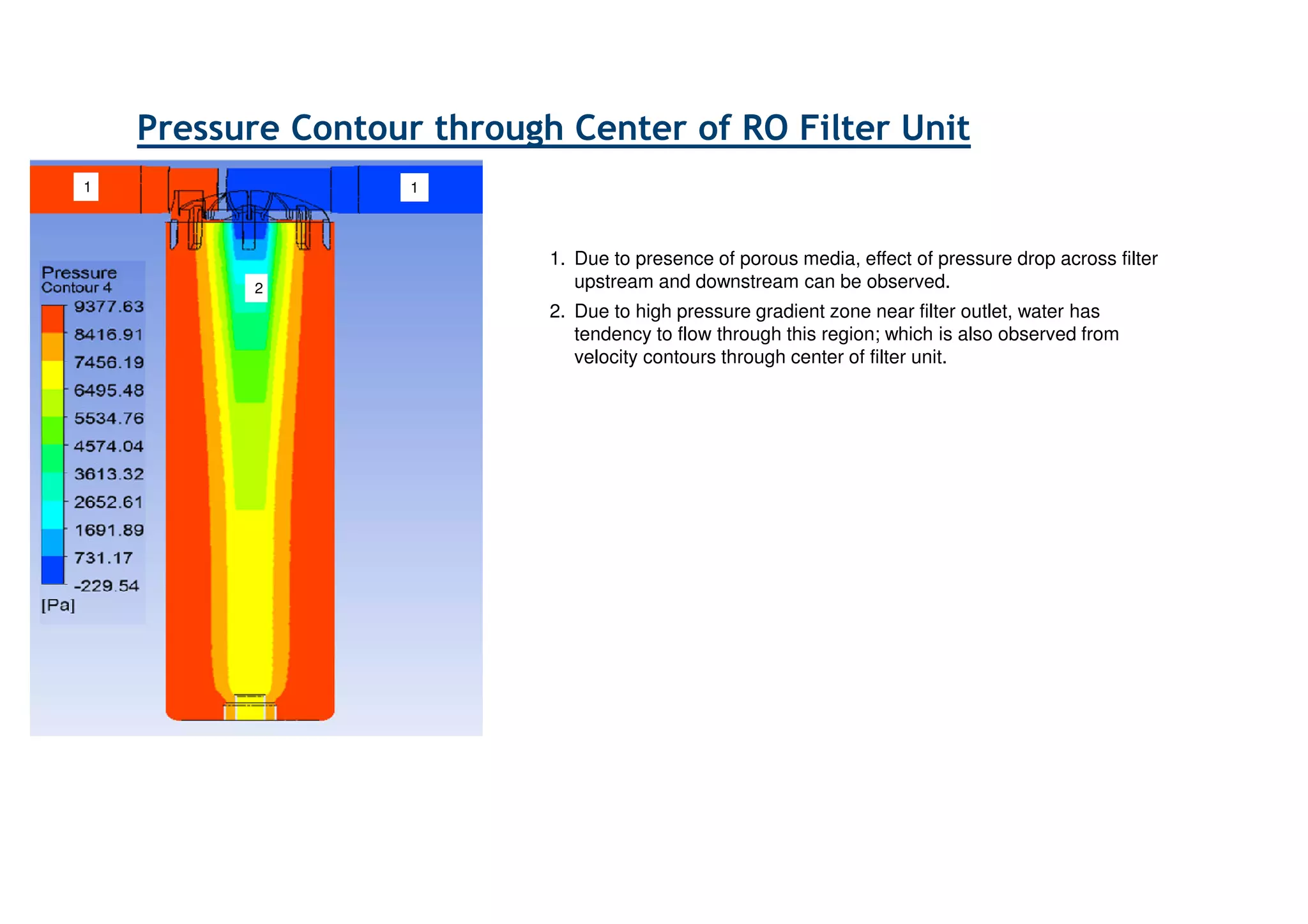

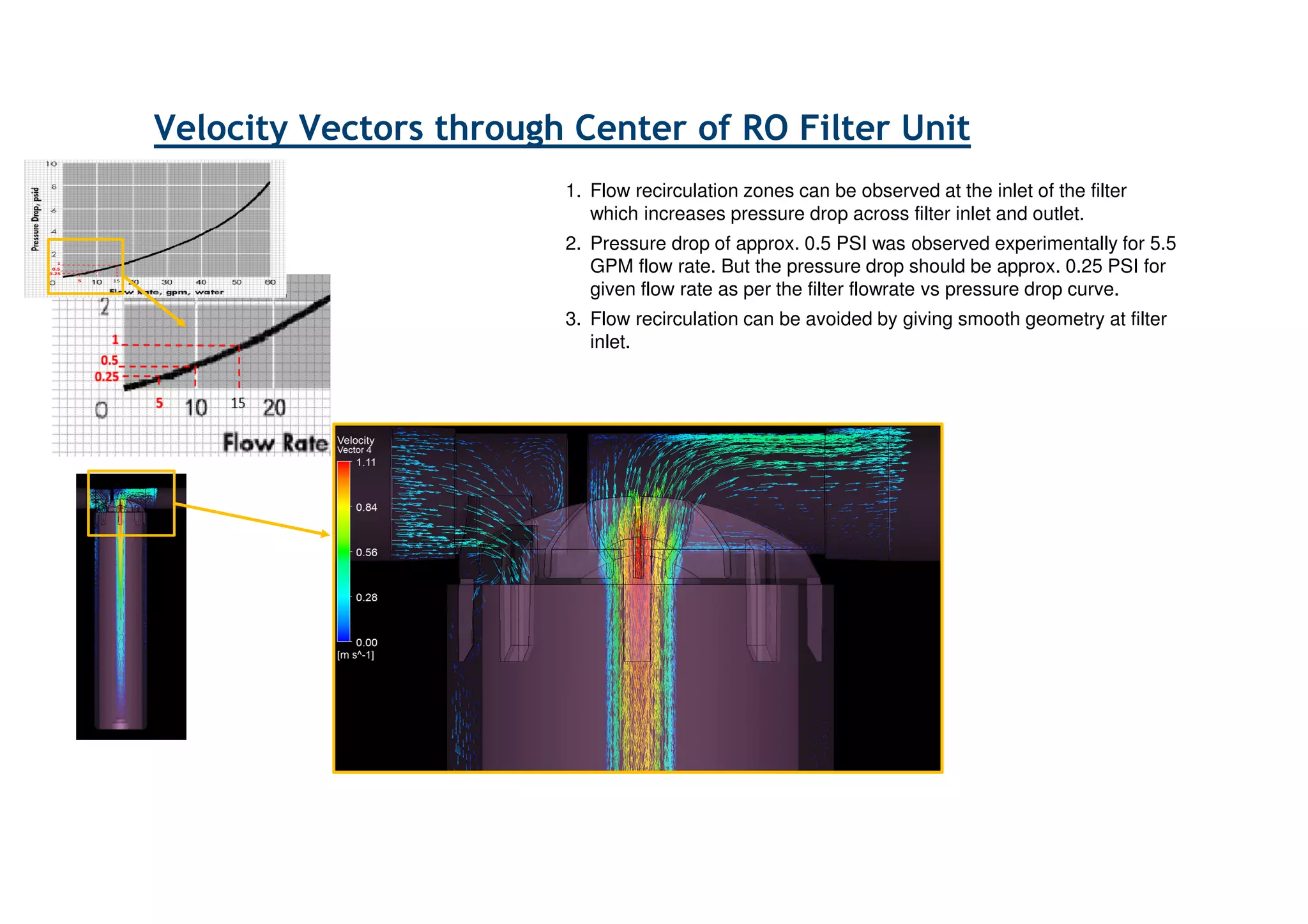

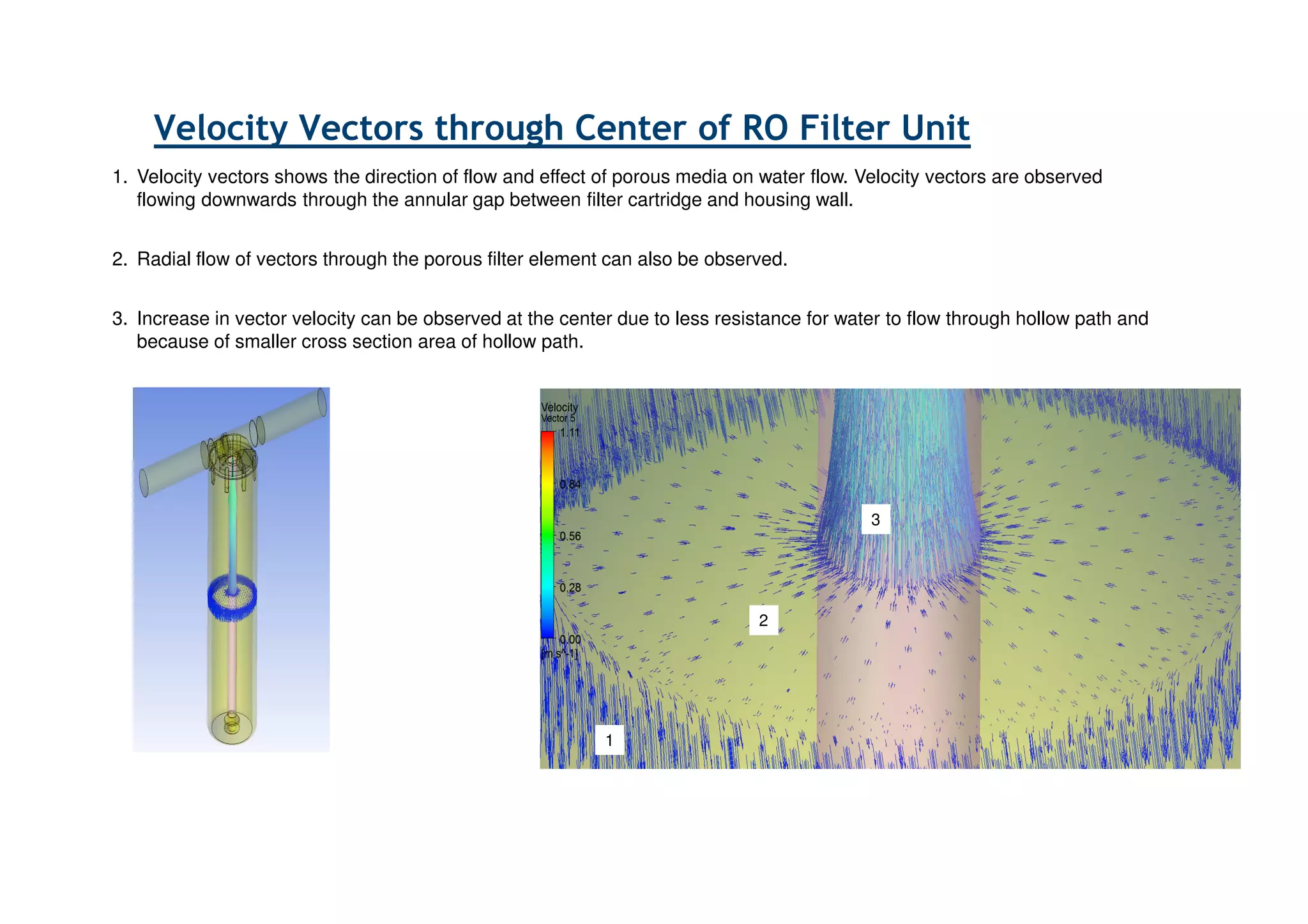

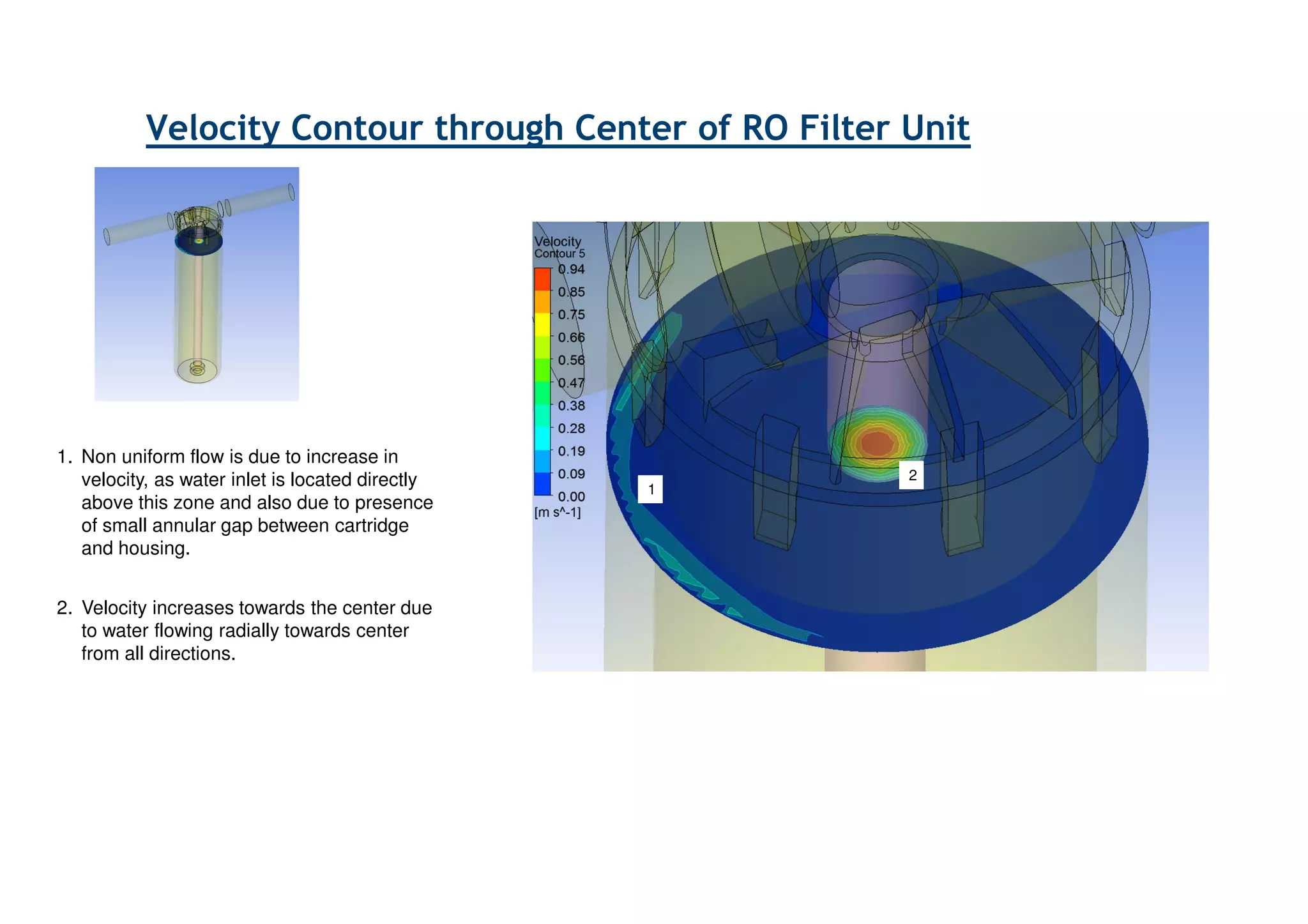

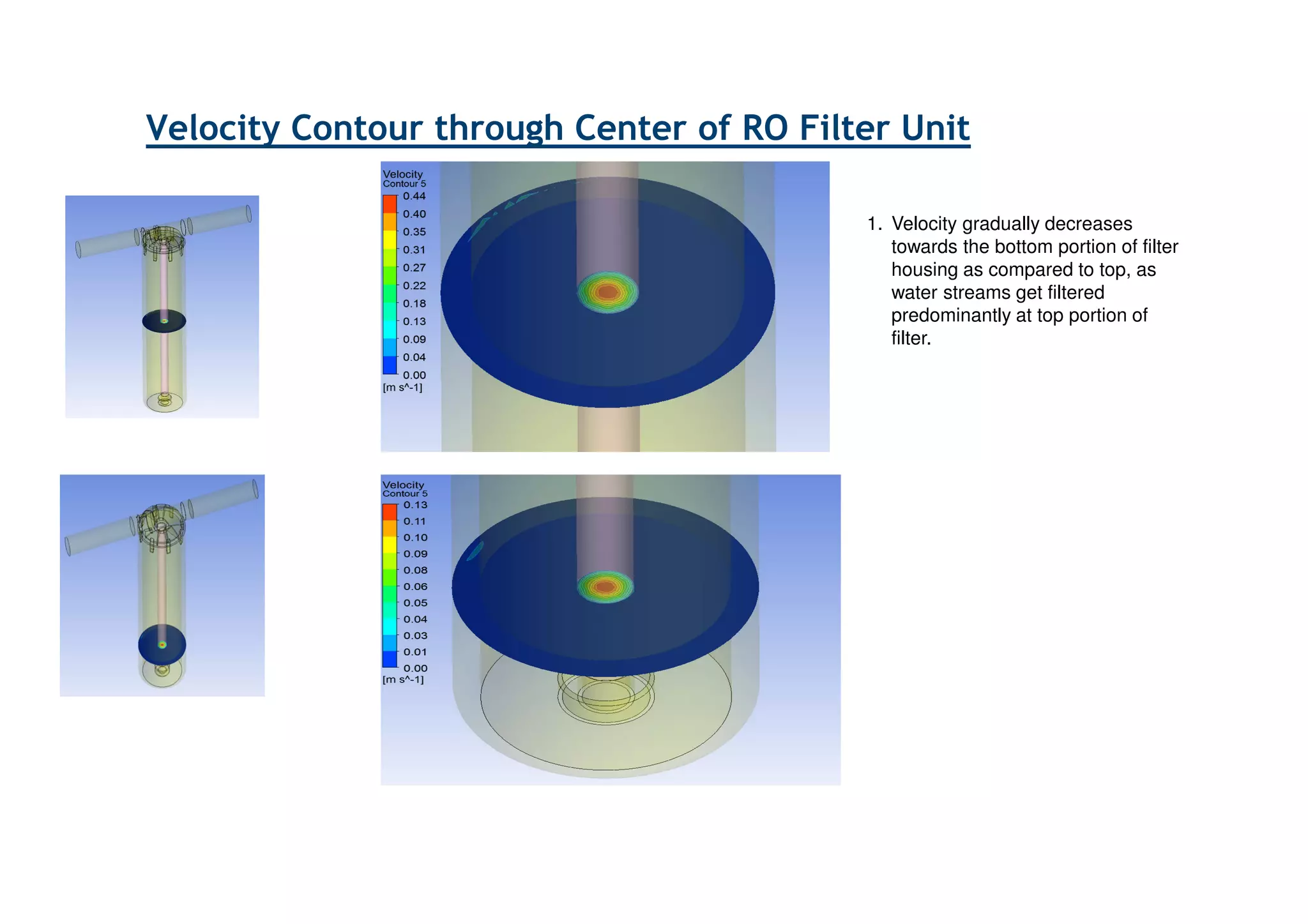

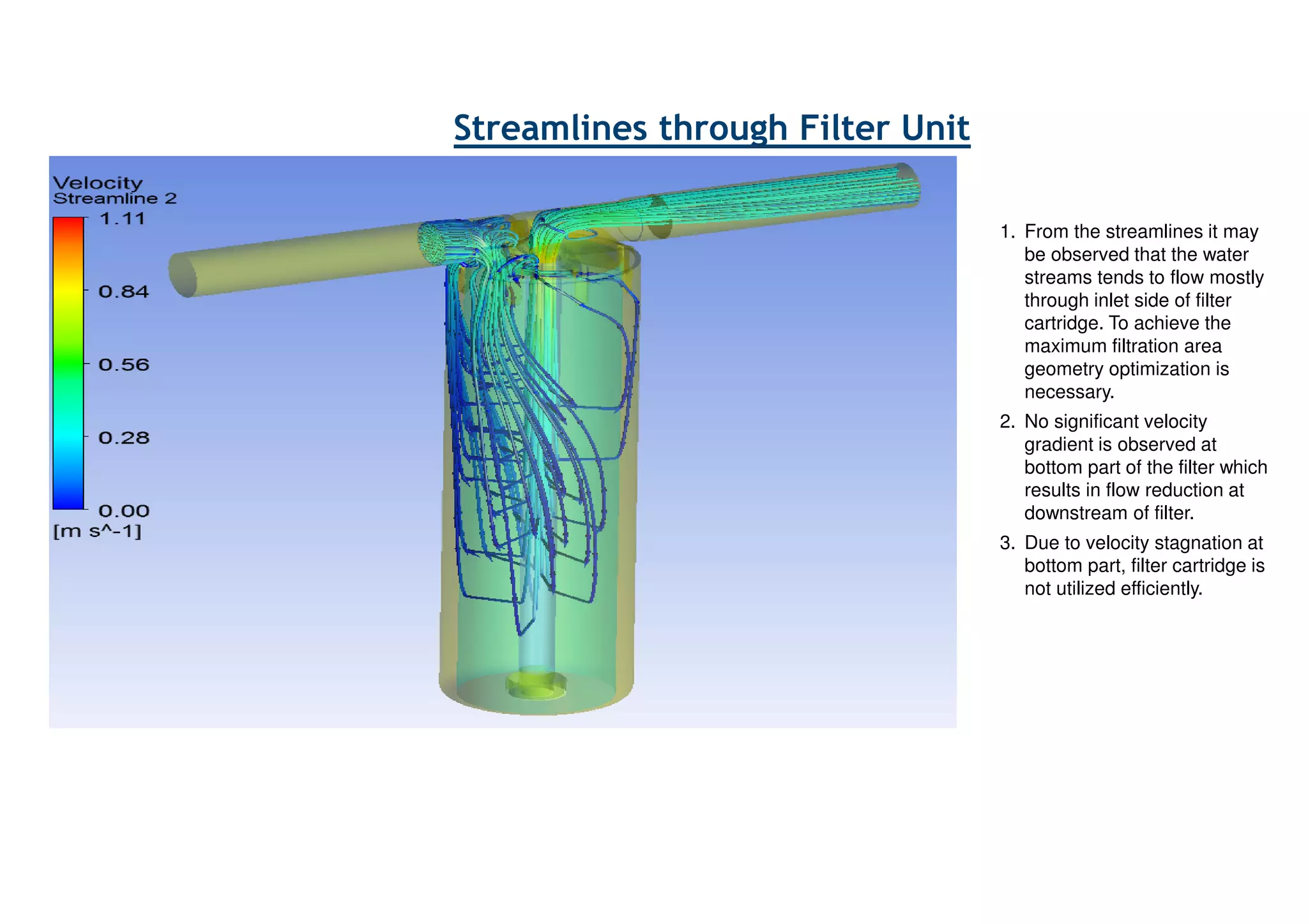

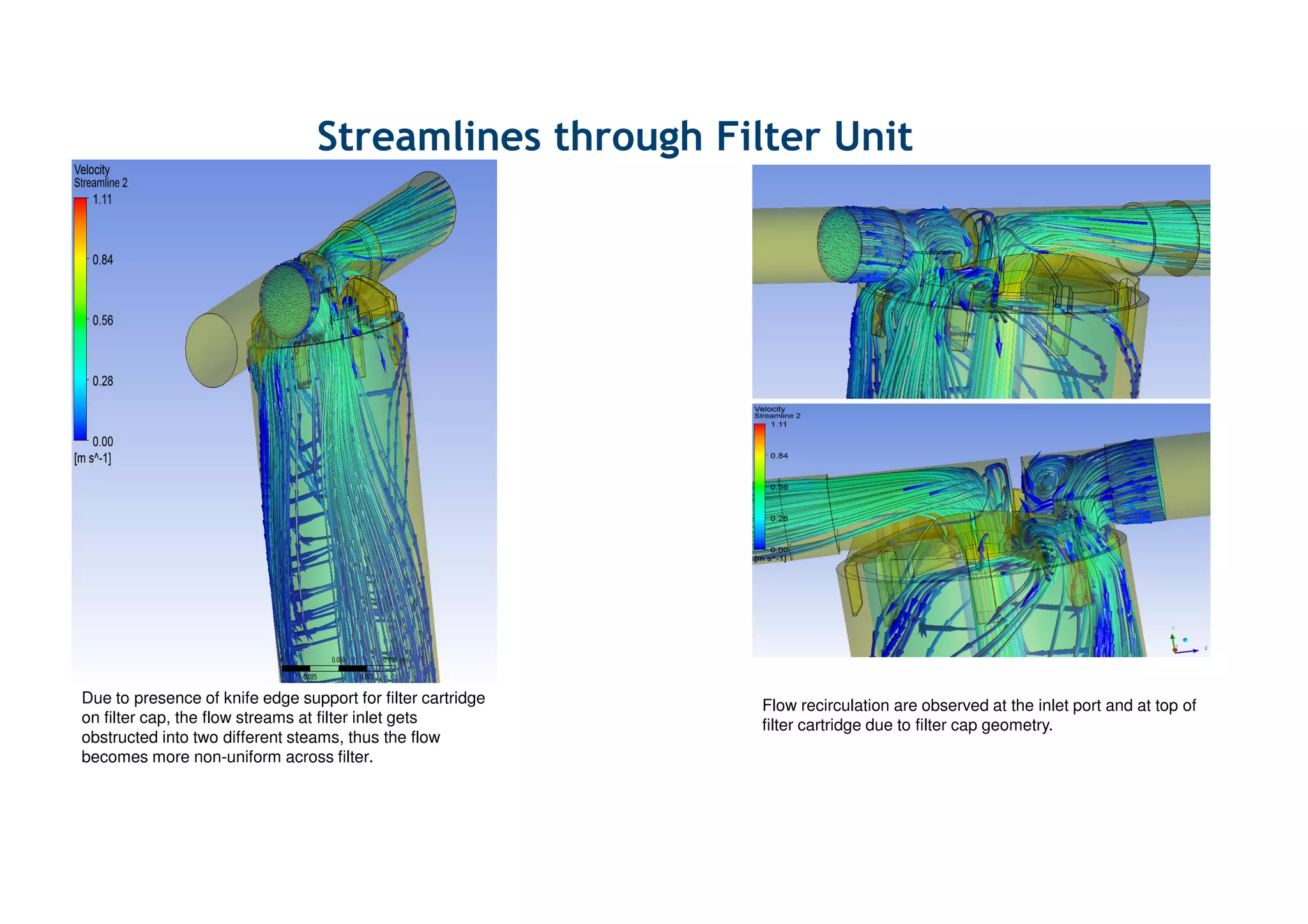

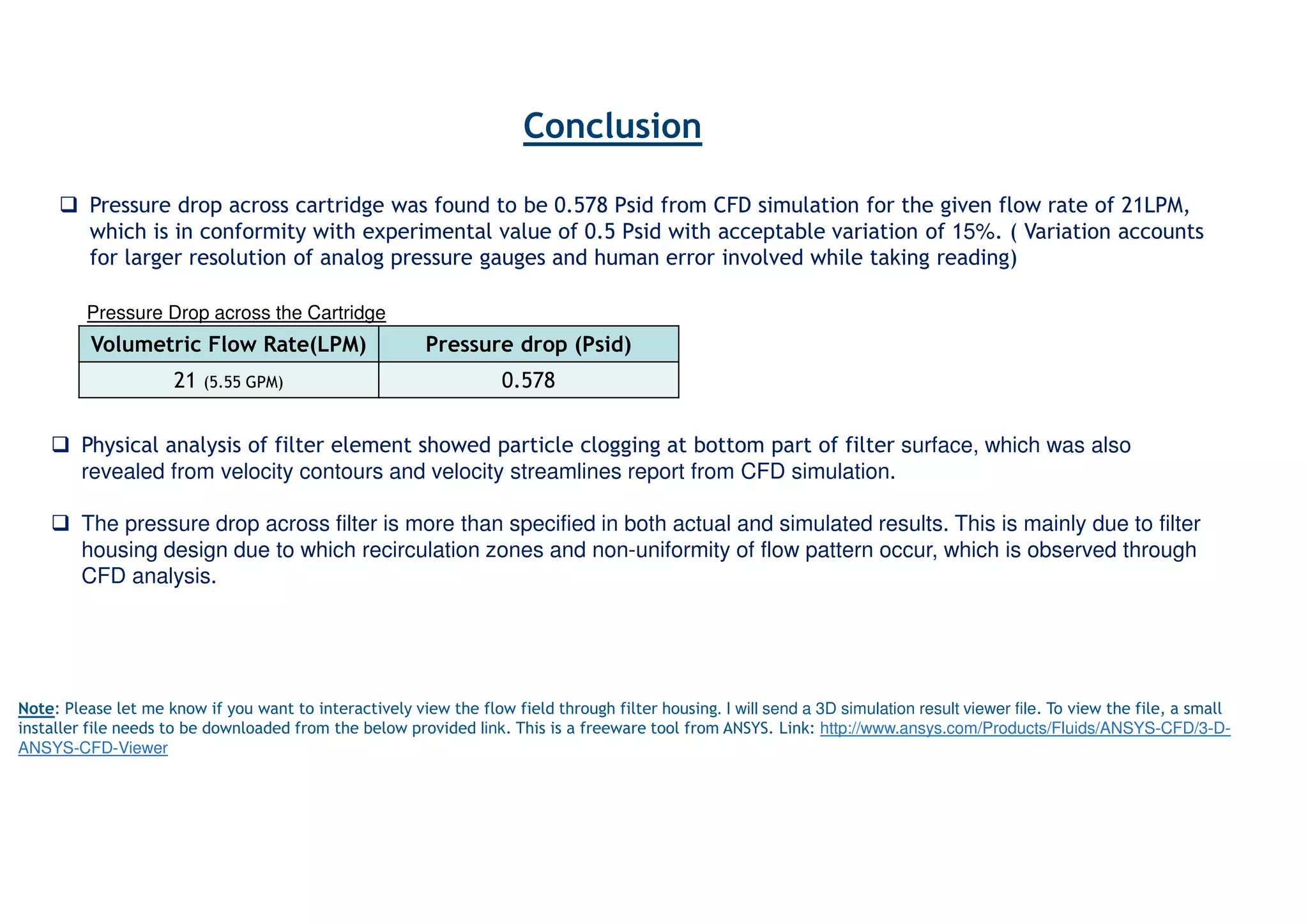

The document details a project aimed at optimizing a polypropylene sediment water filter design using reverse engineering and CFD simulation. It evaluates the flow characteristics, pressure drops, and efficiency of the filter, comparing experimental results with simulated data to identify design improvements. The findings reveal issues like particle clogging and flow recirculation, suggesting a need for geometry optimization to enhance filtration efficiency.