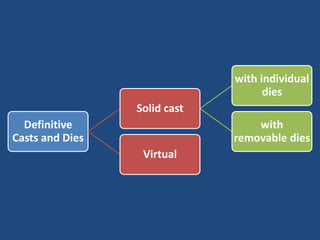

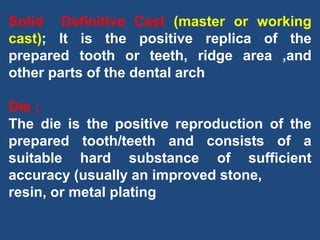

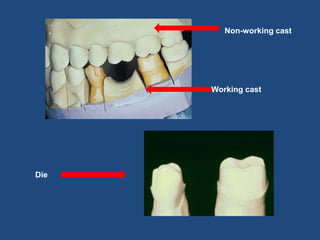

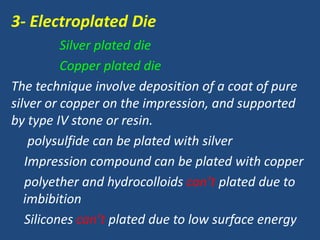

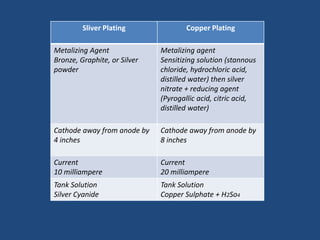

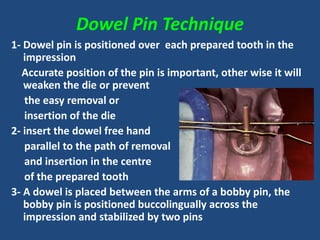

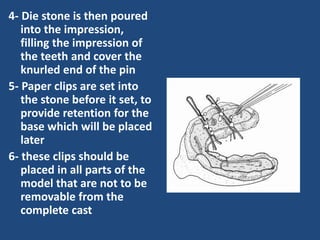

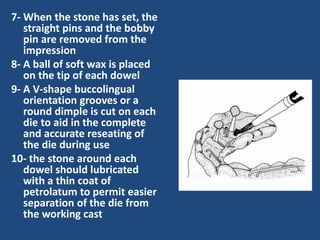

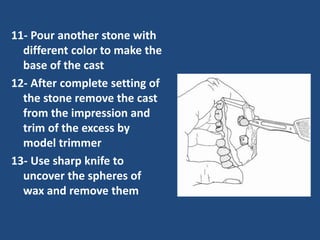

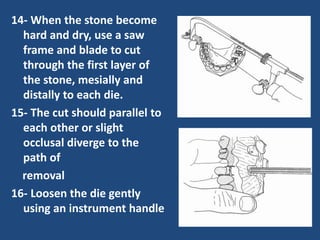

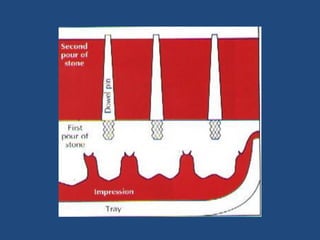

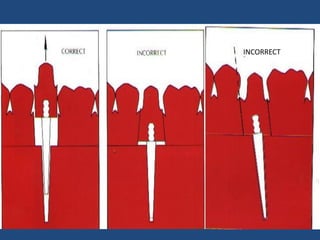

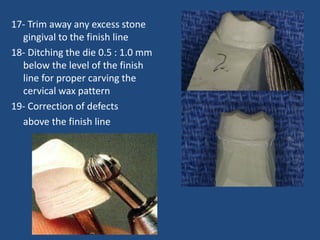

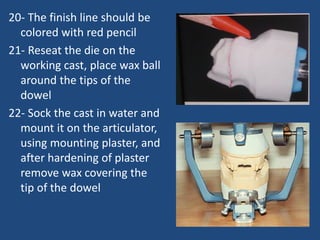

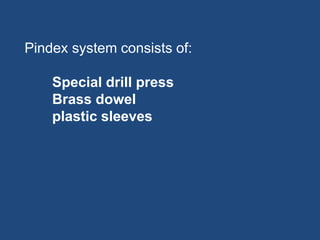

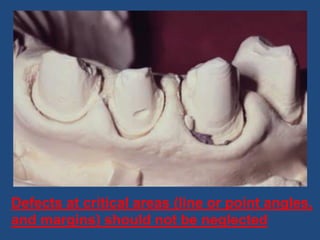

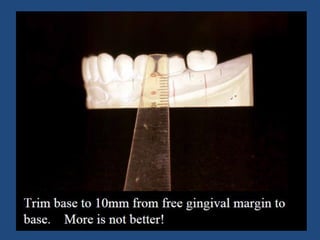

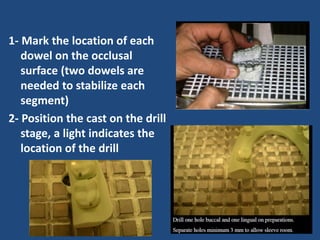

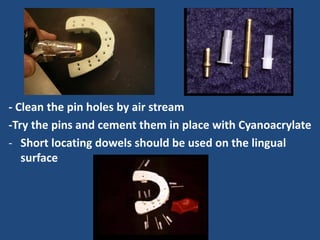

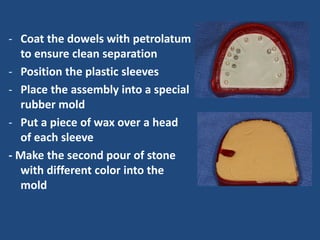

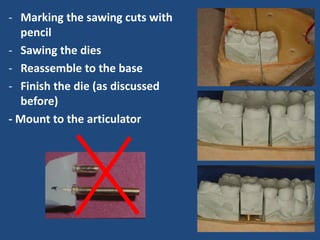

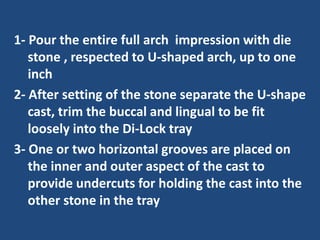

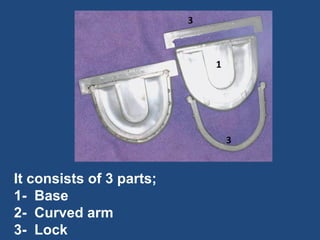

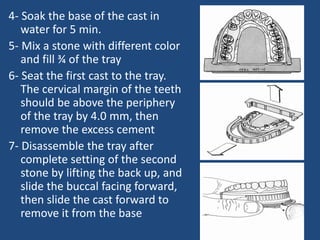

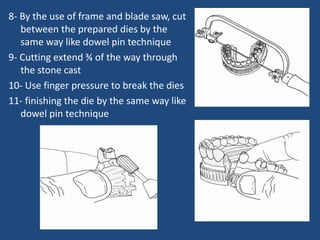

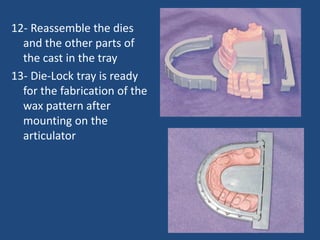

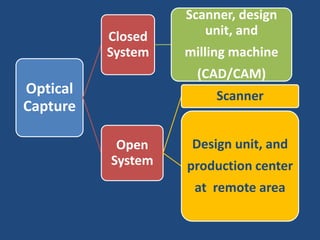

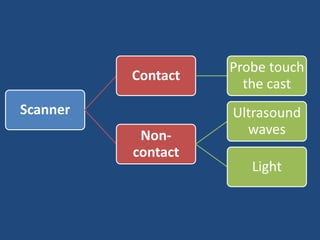

The document discusses definitive casts and dies used in fixed prosthodontics. It defines a definitive cast as a positive replica of the prepared teeth and surrounding structures. A die is the positive reproduction of the prepared tooth. There are several techniques for creating dies that can be removed from the definitive cast, including the dowel pin technique, Pindex system, and Di-Lock tray technique. The document also discusses requirements and various materials used for dies, such as gypsum, resin, electroplated metals, and ceramics. Virtual definitive casts and dies created using CAD/CAM systems are also introduced.