Die - the positive reproduction of the form of a prepared tooth in any suitable substance (GPT-5).

The die for the fixed restoration also must meet certain requirements:

It must reproduce the prepared tooth exactly.

- All surfaces must be accurately duplicated, and no bubbles or voids can be accepted.

Desirable characteristics of a die material:

- accuracy

- reproduce fine detail and sharp margins

- strength

- hardness

- ease of manipulation

- production of die in a short time

- suitable to all types of impression materials

- non-injurious to health

- good color contrast

Classification - Newmann and Williams , 1969

a) METAL DIES :

- Silver and copper amalgam - must condense into a rigid material. Affected by heat. 10-12 hours to harden.

- Electroplated dies

- Copper , 10-15 hour process

- Silver - hydrocyanic gas can be produced

- Bismuth-tin Alloy spray gun at 138 degrees C to impression. Difficult to spray in narrow confined areas

The use of electroformed gold copings as the core of fixed oral prostheses was first introduced by Rogers & Armstrong in 1961 .

DISADVANTAGE :

- Highly toxic electrolyte , need for large expensive equipment .

In 1970 Wismann developed thiosulfate electrolyte system .

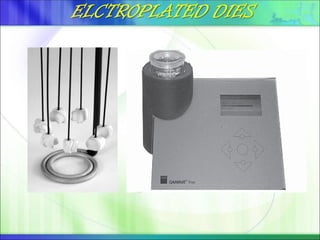

In 1991 a new, much smaller system developed by Gramm Technik - less expensive .

- Electrodeposition of 24-Kt gold copings directly onto a stone die would seem to offer the potential for less distortion and misfit .

Thicknesses of 0.2mm

The areas to be plated are first coated with finely powdered silver or graphite .

The impression is then placed in an electroplating bath .

A layer of pure metal is deposited on the impression and is supported with Type IV stone or resin.

performed slowly – TYPICALLY TAKES 8 hrs .

silicone impression materials are difficult to electroplate evenly –low surface energy .

Polyether - hydrophilic nature, imbibe water and become distorted - cannot be plated accurately

STONE DIES :

- Type IV and Type V gypsum products .

- The materials are capable of reproducing a 20-um-wide line as prescribed by ADA specification No. 19 .

- Setting and thermal expansion compensate for the casting shrinkage .

- Gypsum's greatest disadvantage is its relatively poor resistance to abrasion .

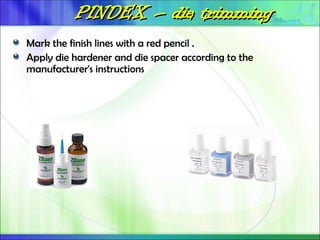

- To overcome this disadvantage - DIE HARDENER

Materials like colloidal silica , cyanoacrylate , gum arabic , calcium hydroxide , polystyrene - added or coated to gypsum to improve abrasion resistance .

Methods- soaking or boiling dies , coating , air thinning , brush thinning , shaking .

Composition of a typical die hardener :

- Methyl Ethyl ketone or any solvent = 75%

acrylic resin or Methyl Methaacrylate = 25%

Little effect on the hardness of the stone, they improve abrasion resistance .

Slight increase in setting expansion.

Abrasion resistance most improved by impregnate the surface of the die with a low-viscosity resin such as cyanoacry