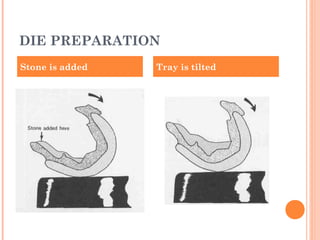

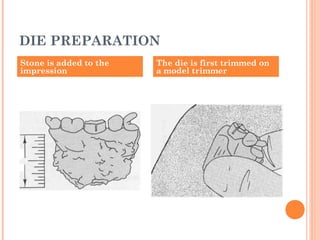

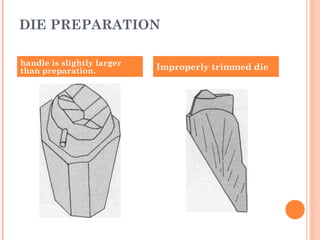

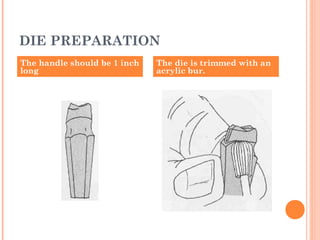

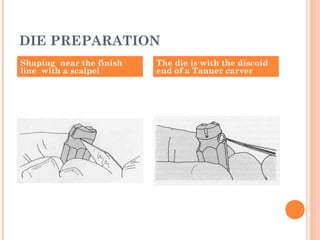

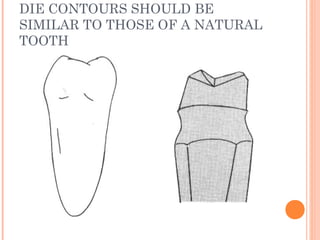

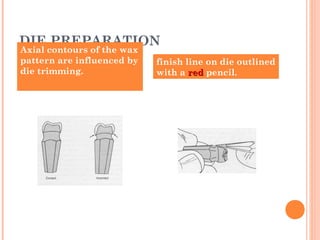

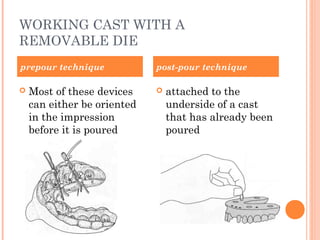

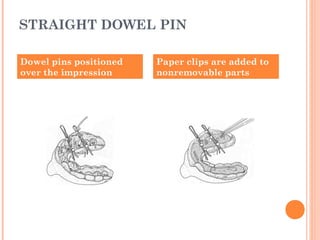

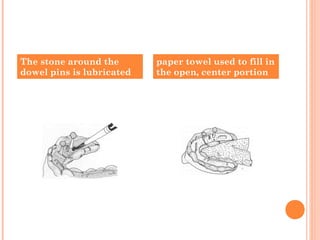

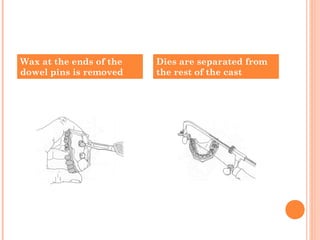

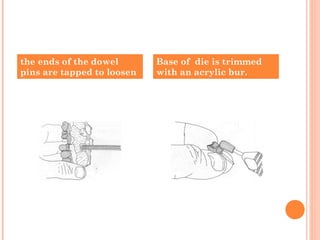

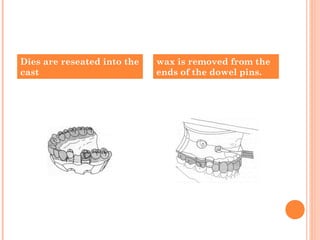

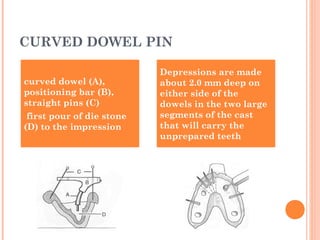

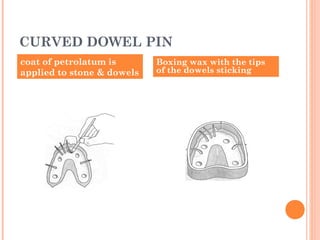

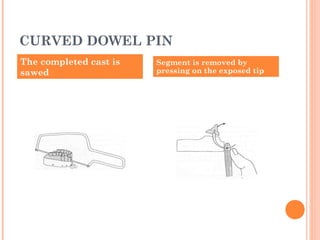

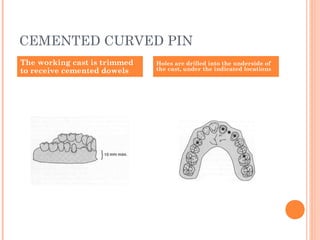

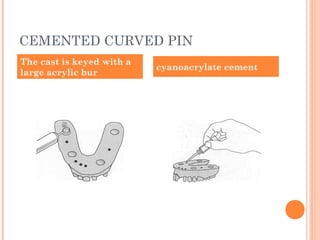

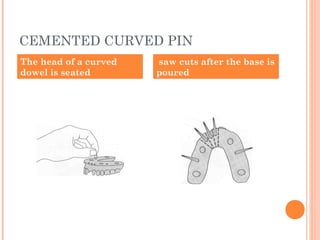

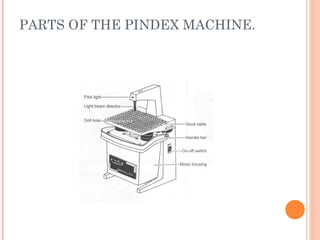

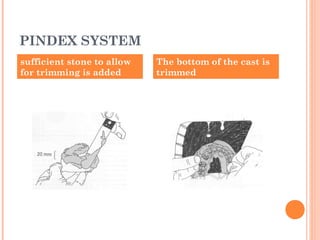

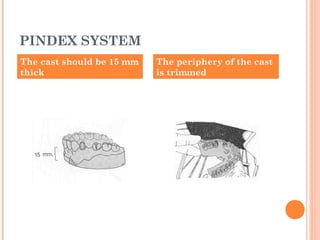

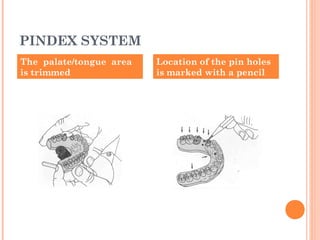

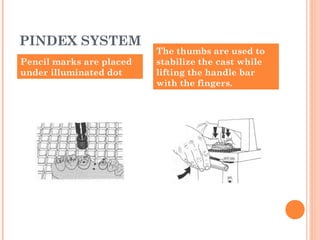

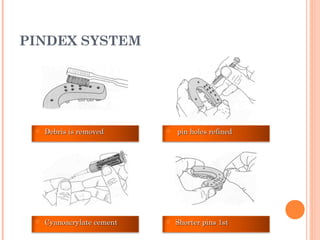

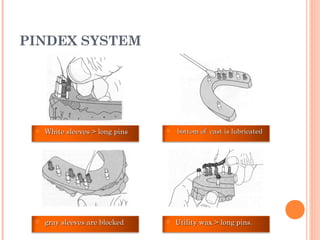

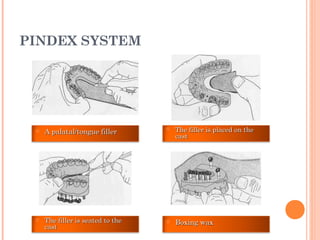

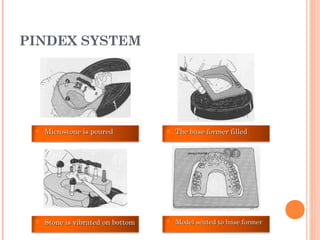

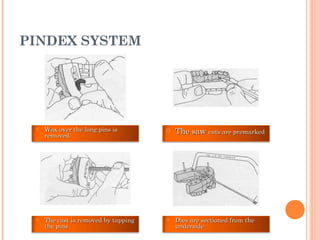

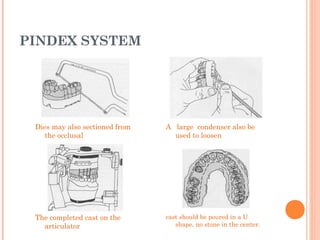

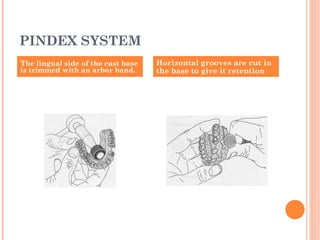

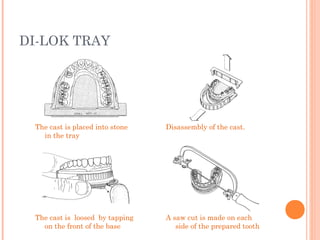

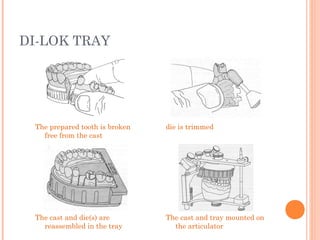

The document discusses different techniques for creating working casts with removable dies, including straight and curved dowel pins, pindex systems, and Di-Lok trays. Removable dies allow the fabrication of wax patterns on individual teeth and must return to their exact positions to ensure accurate articulation. Proper die preparation, such as trimming without reducing access or altering contours, is important for producing casts that facilitate wax pattern fabrication.