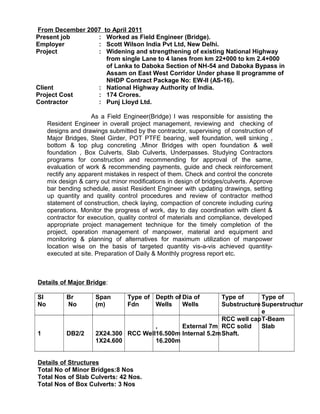

Debajit Dhar has over 21 years of experience in bridge engineering and highway construction. He holds a B.E. in Civil Engineering and additional qualifications in quality assurance. Currently he works as a bridge engineer on a highway project in Assam, where his responsibilities include supervising bridge construction, reviewing designs, and ensuring quality control. Previously he has worked on several major bridge and highway projects throughout India and Qatar.