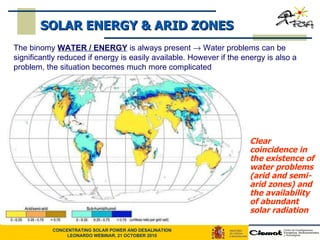

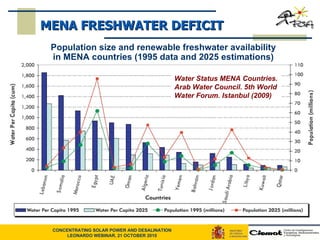

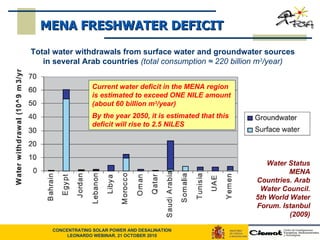

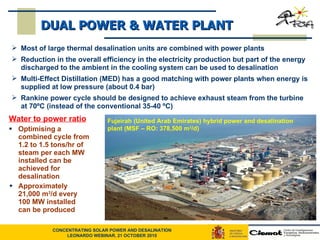

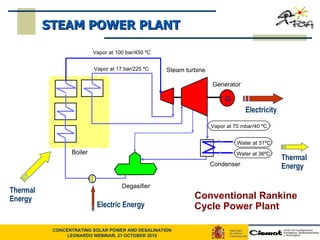

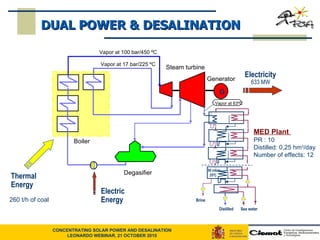

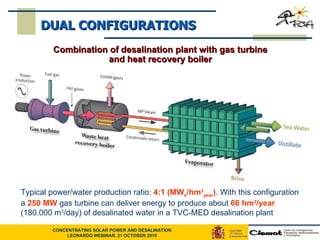

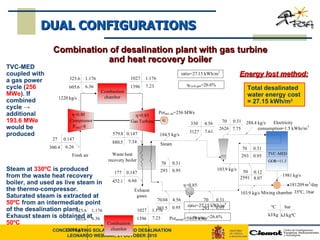

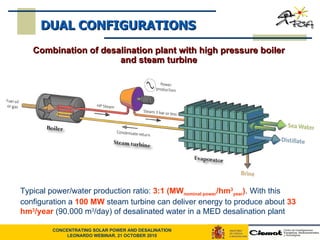

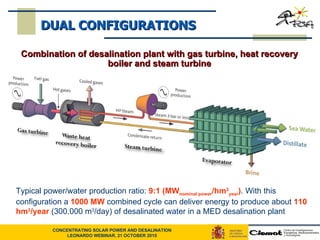

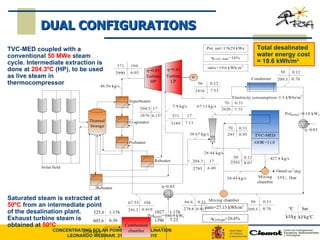

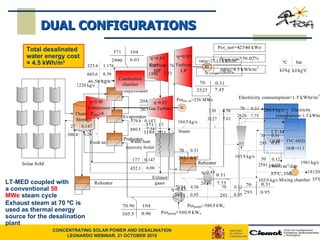

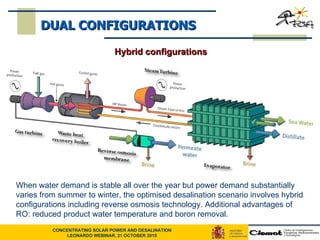

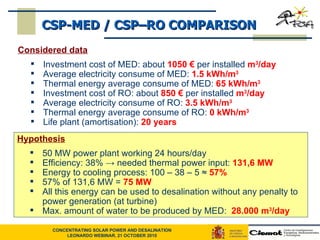

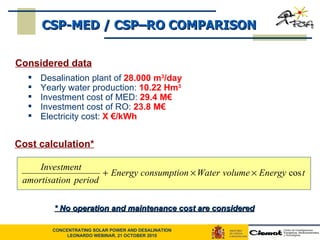

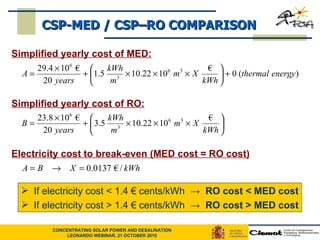

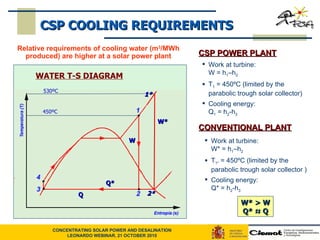

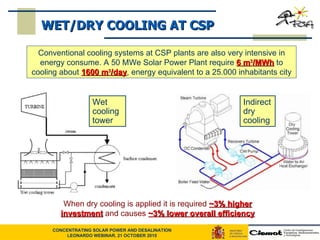

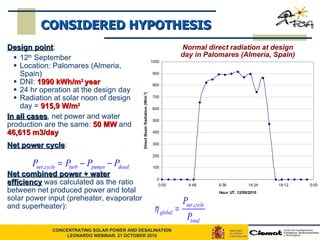

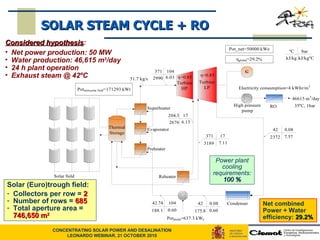

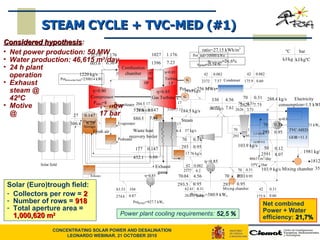

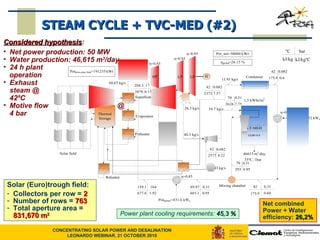

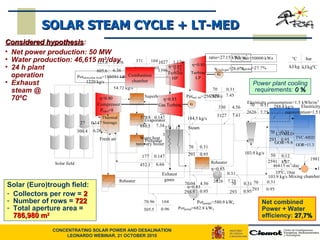

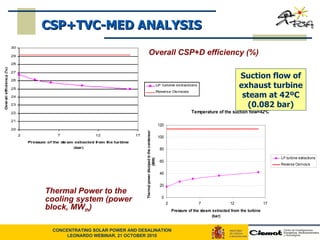

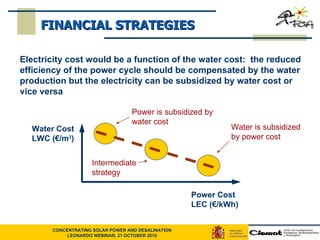

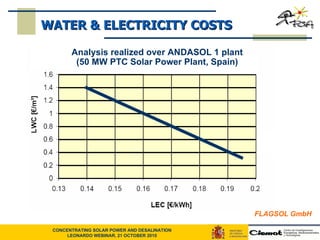

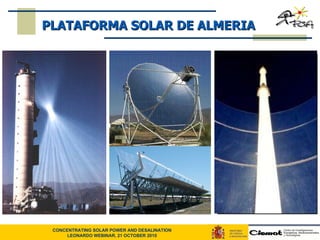

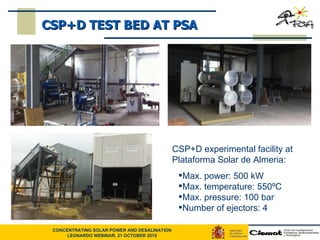

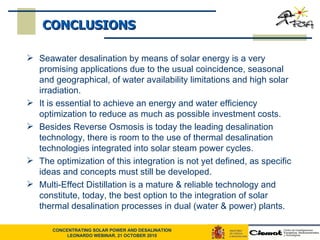

The document discusses the integration of concentrated solar power (CSP) and desalination processes (CSP+D) to address water scarcity issues in arid regions, particularly in the MENA region. It highlights the potential benefits of CSP+D, including technological synergies and financial advantages, as well as challenges such as location constraints and unresolved technological issues. The document concludes that while reverse osmosis is the leading desalination technology, there remains potential for thermal desalination methods like multi-effect distillation to be optimized in conjunction with solar power systems.

![Dr. Julián Blanco Plataforma Solar de Almeria [email_address] CONCENTRATING SOLAR POWER AND DESALINATION Solar Desalination Webinar #2 21 October 2010](https://image.slidesharecdn.com/2-concentratingsolarpoweranddesalinationv2-101020075447-phpapp01/75/CSP-Training-series-solar-desalination-2-2-1-2048.jpg)