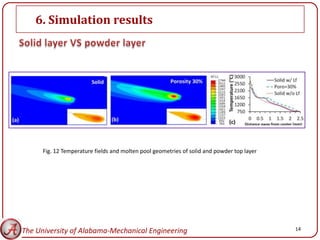

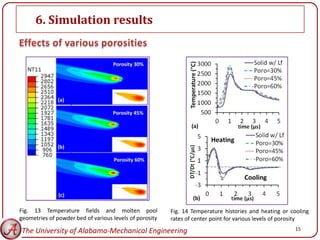

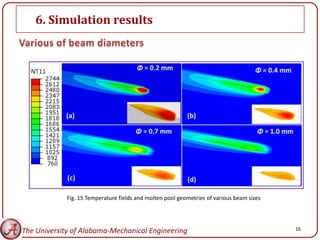

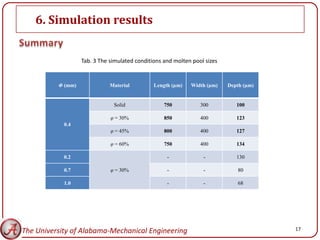

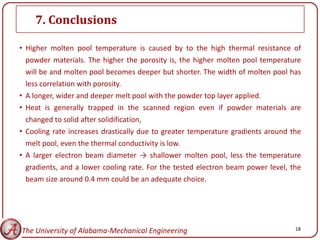

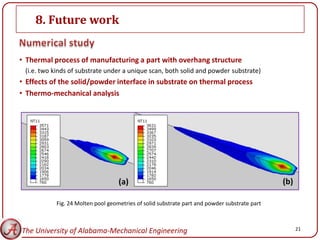

This document summarizes research on modeling the thermal effects of the electron beam additive manufacturing process, specifically how powder sintering affects temperature distribution and melt pool geometry. Key findings from simulations include higher temperatures and deeper melt pools with increasing powder porosity. Larger beam sizes produced shallower melt pools. Future work is proposed on modeling overhang structures, thermal effects at solid/powder interfaces, and thermo-mechanical analysis.

![1. Introduction and research objectives

Fig. 1 Melt ball formation [2]

Fig. 2 Delamination [2] 4

The University of Alabama-Mechanical Engineering](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-4-320.jpg)

![2. Heat transfer and heat source modeling

• The cross sectional geometry of keyhole is usually idealized as a cone

• The intensity distribution is considered as a conical source:

Horizontal – Gaussian distribution

Vertical – Decaying with increasing of penetration depth

Fig. 5 Actual keyhole example and idealization [3]

The University of Alabama-Mechanical Engineering 7](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-7-320.jpg)

![2. Heat transfer and heat source modeling

Heat source equation used in our study [4]:

2 2

8 UIb 8 x xs y ys

2 z

S x, y, z f z 2

exp 2 with f z 1

E E

h h

Max. density = 306 W/mm2

U 6 0 kV

Ib 2mA

If E

2mm

1

h 2mm

z 0

Fig. 6 Horizontal intensity distribution @ z = 0

The University of Alabama-Mechanical Engineering 8](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-8-320.jpg)

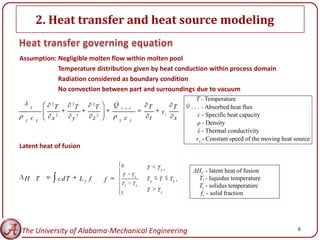

![3. Material properties & state changes

Fig. 7 Temperature dependent material properties of Ti-6Al-4V [5]

The University of Alabama-Mechanical Engineering 9](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-9-320.jpg)

![3. Material properties & state changes

Emissivity [6]: Thermal Conductivity [7]:

AH H

1 AH S

2 k kr kc

1

S

2 3 .0 8 2

2

0.908 16

AH 2 H 2 kc l T

3 kr k b u lk x

1.908 2 1 1

1 3 .0 8 2 1 3

S

εS – Emissivity of solid material

εH – Emissivity of the hole among adjacent powder particles

f – Fraction of total cavity surface

AH – The area fraction of the surface that is occupied by the radiation emitting holes

d – Mean pore diameter

D – Particle size

φ – Fractional porosity of the bed

l – Mean photon free path between scattering events, the particle diameter in this study

σ – Stefan-Boltzmann constant,

T – Temperature

x = b/R – Ratio of neck radius to particle radius

Λ – Normalized contact conductivity for the three packing structures.

The University of Alabama-Mechanical Engineering 10](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-10-320.jpg)

![4. FE model configuration

Tab. 2 Parameters in the simulation

Parameters Values

Solidus temperature, TS ( C) 1605 [8]

Liquidus temperature, TL ( C) 1665 [8]

Latent heat of fusion, Lf (kJ/Kg) 440 [8]

Electron beam diameter, Φ (mm) 0.2, 0.4, 0.7, 1.0

Absorption efficiency, η 0.9 [2]

Scan speed, v (mm/sec) 400 [2]

Acceleration voltage, U (kV) 60 [2]

Beam current, Ib (mA) 0.002 [2]

Powder layer thickness, t-layer (mm) 0.1 [2]

Porosity, φ 0, 0.3, 0.45,0.6

Beam penetration depth, dP (mm) 0.1[2]

Fig. 9 New FE model configuration

Preheat temperature, Tpreheat ( C) 760 [2]

The University of Alabama-Mechanical Engineering 12](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-12-320.jpg)

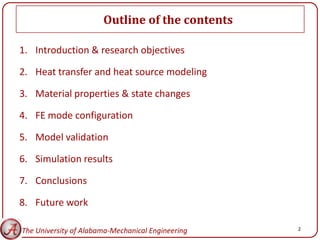

![5. Model validation

Fig. 10 Model geometry, ICs and BCs [9]

Fig. 11 Simulation results comparison with Wang et al [9]:

a) Temperature contour; b) Temperature distribution along beam center scan pass

The University of Alabama-Mechanical Engineering 13](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-13-320.jpg)

![Reference

[1] Available from: http://www.arcam.com/.

[2] Zaeh, M. F., and Lutzmann, S., 2010, "Modelling and simulation of electron beam melting," Production

Engeering. Research and Development, 4, pp. 15-23.

[3] Lampa, C., Kaplan, A. F. H., Powell, J., and Magnusson, C., 1997, "An analytical thermodynamic model of laser

welding," Journal of Physics D: Applied Physics, 30(9), p. 1293.

[4] Rouquette, S., Guo, J., and Le Masson, P., 2007, "Estimation of the parameters of a Gaussian heat source by

the Levenberg-Marquardt method: Application to the electron beam welding," International Journal of

Thermal Sciences, 46(2), pp. 128-138.

[5] Yang, J., Sun, S., Brandt, M., and Yan, W., 2010, "Experimental investigation and 3D finite element prediction

of the heat affected zone during laser assisted machining of Ti6Al4V alloy," Journal of Materials Processing

Technology, 210(15), pp. 2215-2222.

[6] Sih, S. S., and Barlow, J. W., 2004, "The prediction of the emissivity and thermal conductivity of powder beds,"

Particulate Science and Technology, 22, pp. 291-304.

[7] Kolossov, S., Boillat, E., Glardon, R., Fischer, P., and Locher, M., 2004, "3D FE simulation for temperature

evolution in the selective laser sintering process," International Journal of Machine Tools and Manufacture,

44(2-3), pp. 117-123.

[8] Boyer, R., Welsch, G., and Collings, E. W., 1998, "Materials Properties Handbook: Titanium Alloys," ASM

InternationalMaterials Park, OH, USA, pp. 483-636.

[9] Wang, L., Felicelli, S., Gooroochurn, Y., Wang, P. T., and Horstemeyer, M. F., 2008, "Optimization of the LENS

process for steady molten pool size," Materials Science & Engineering A (Structural Materials: Properties,

Microstructure and Processing), 474, pp. 148-156.

[10] Hofmeister, W., Wert, M., Smugeresky, J., Philliber, J. A., Griffith, M., and Ensz, M. T., 1999, "Invesitigation of

solidification in the Laser Engineered Net Shaping (LENS) process," JOM, 51(7).

The University of Alabama-Mechanical Engineering 24](https://image.slidesharecdn.com/msec2012-130214121537-phpapp01/85/Thermal-Modeling-of-Electron-Beam-Additive-Manufacturing-Process-Powder-Sintering-Effects-24-320.jpg)