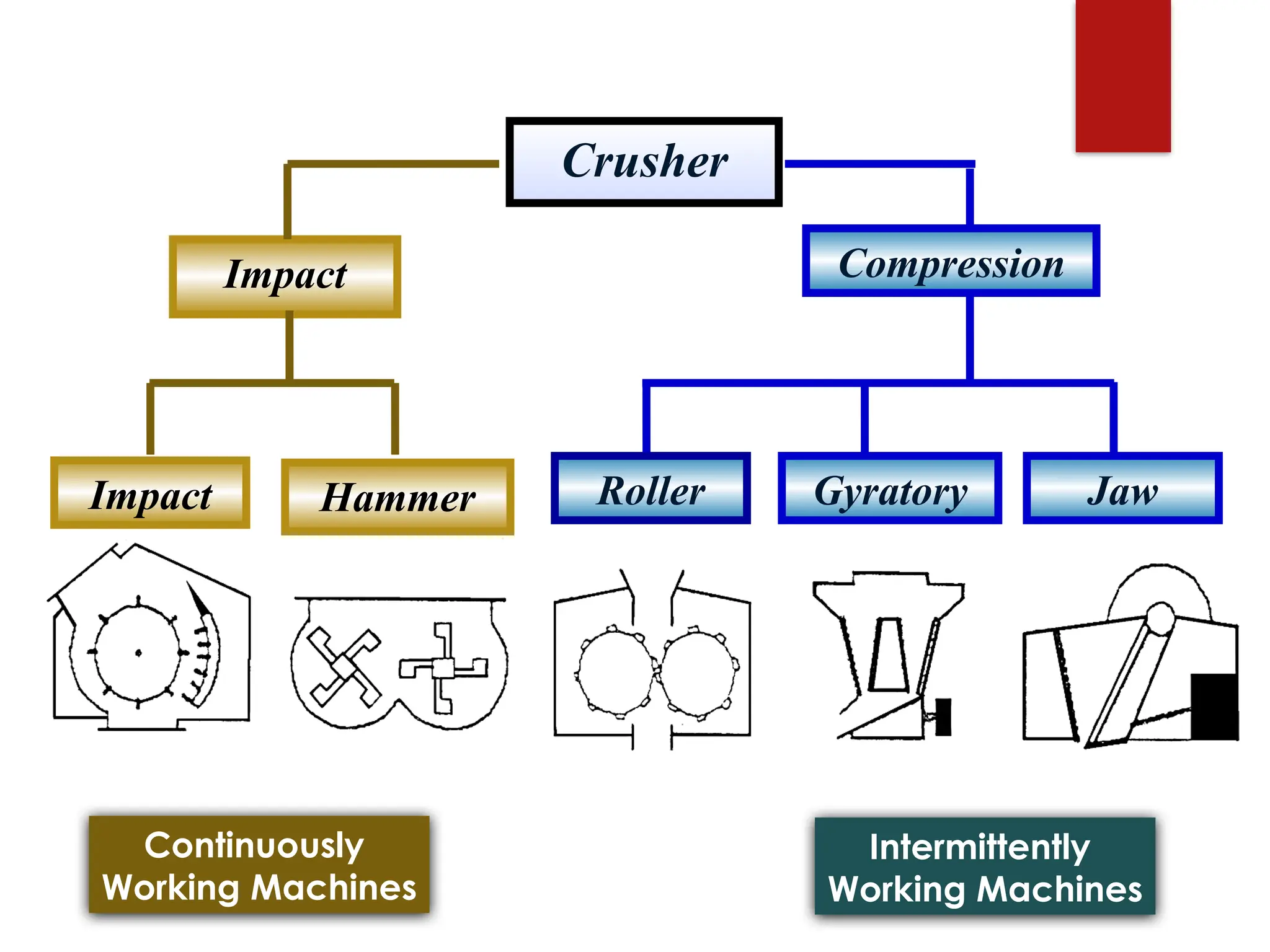

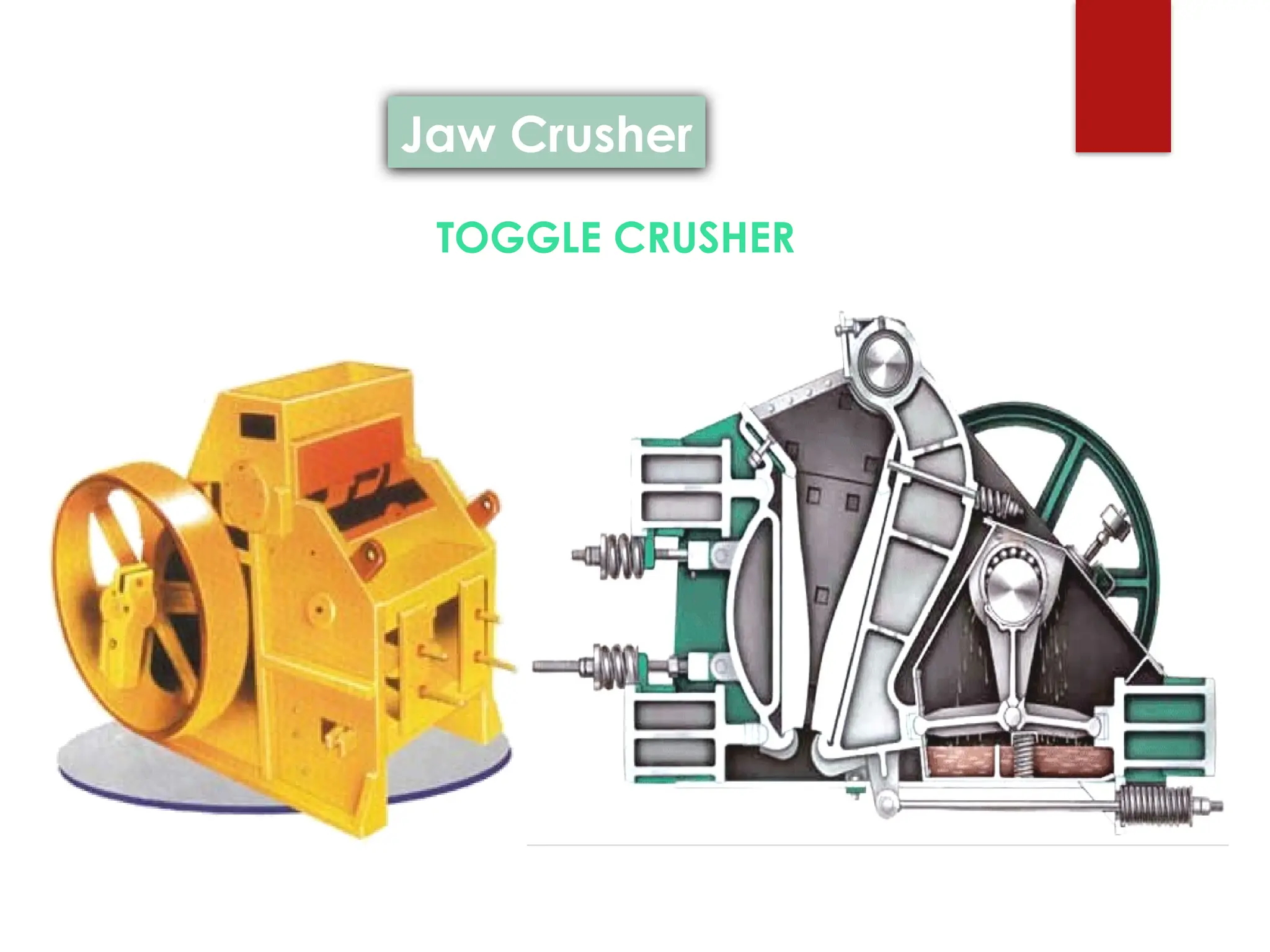

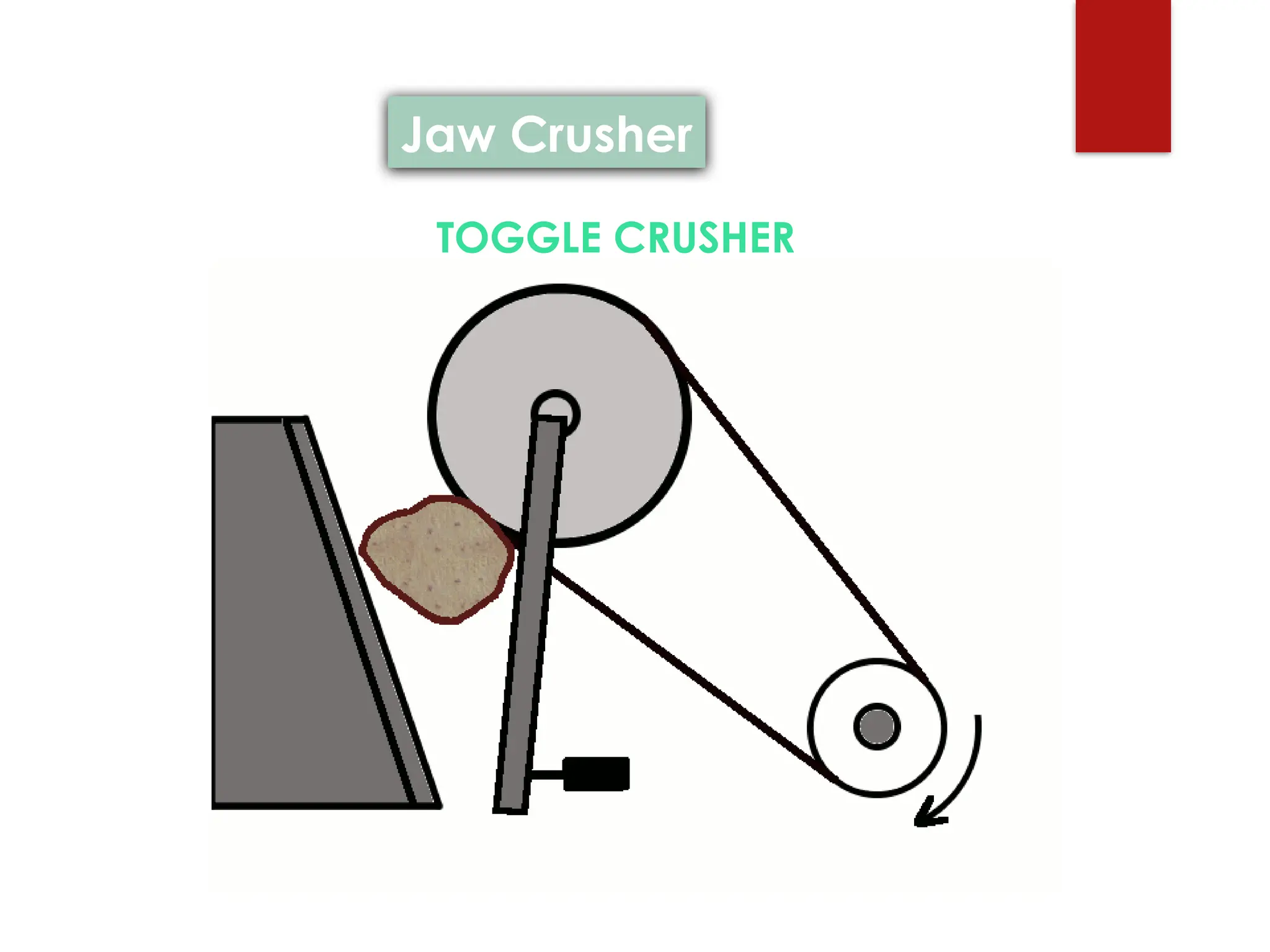

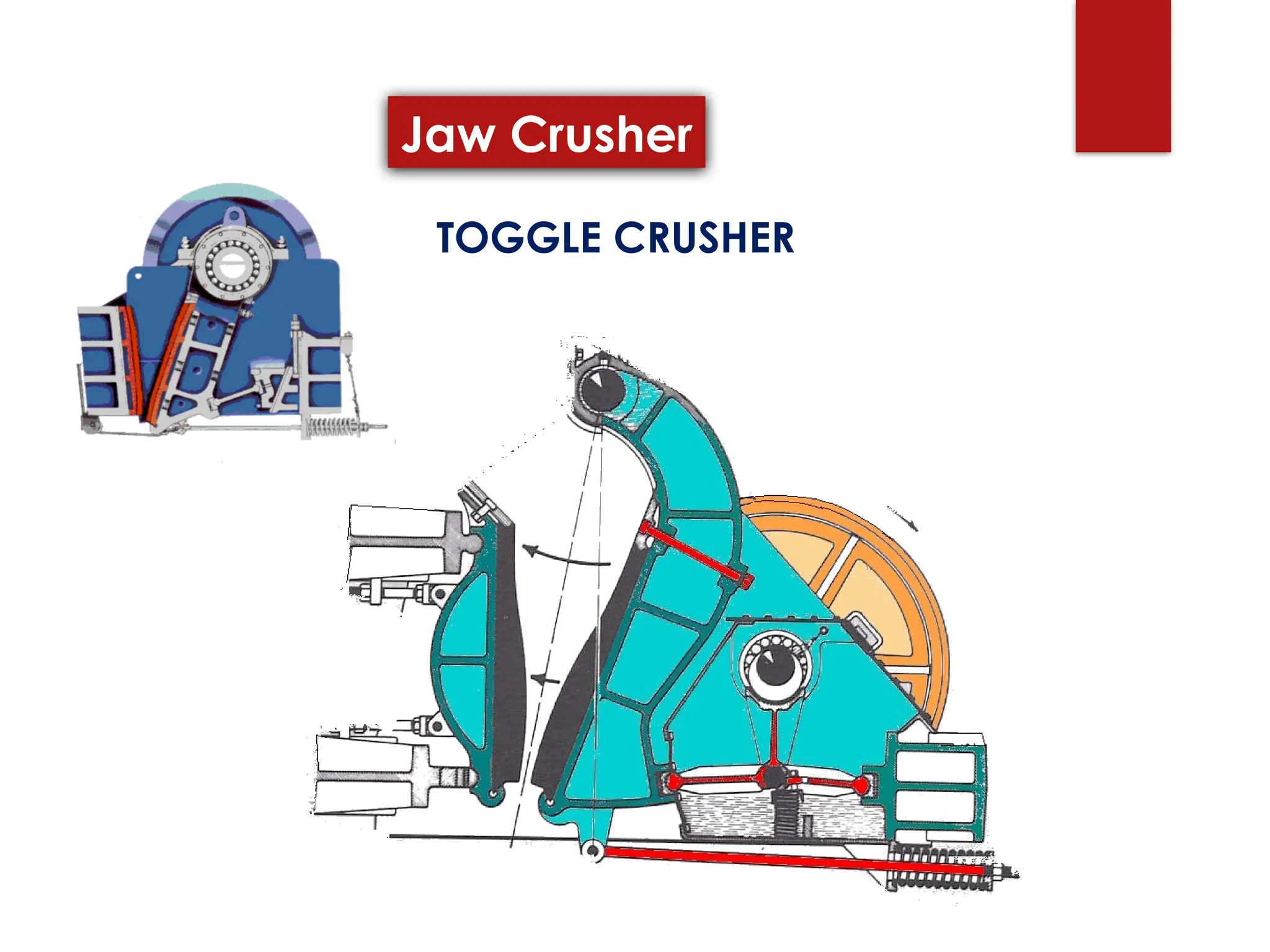

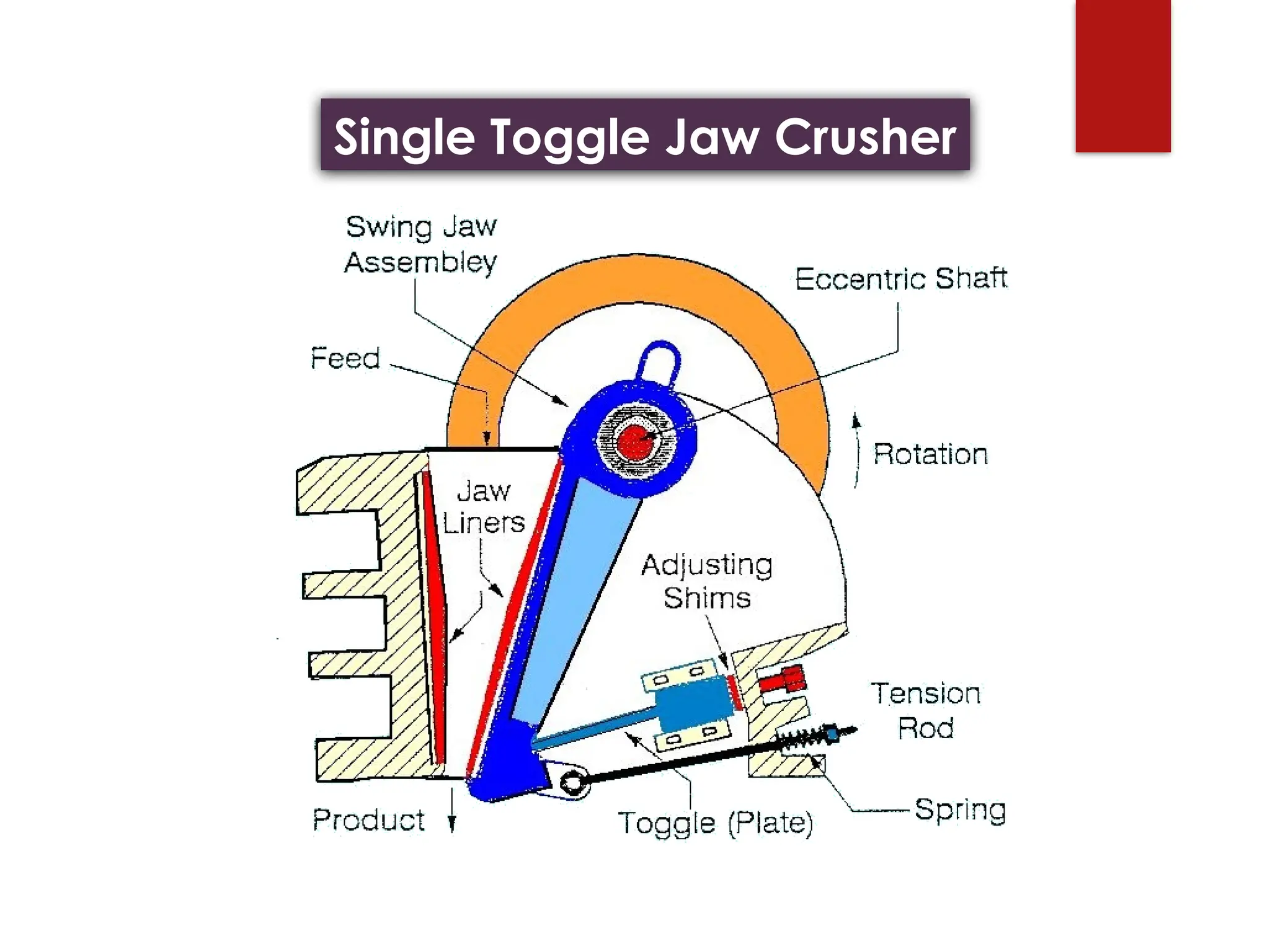

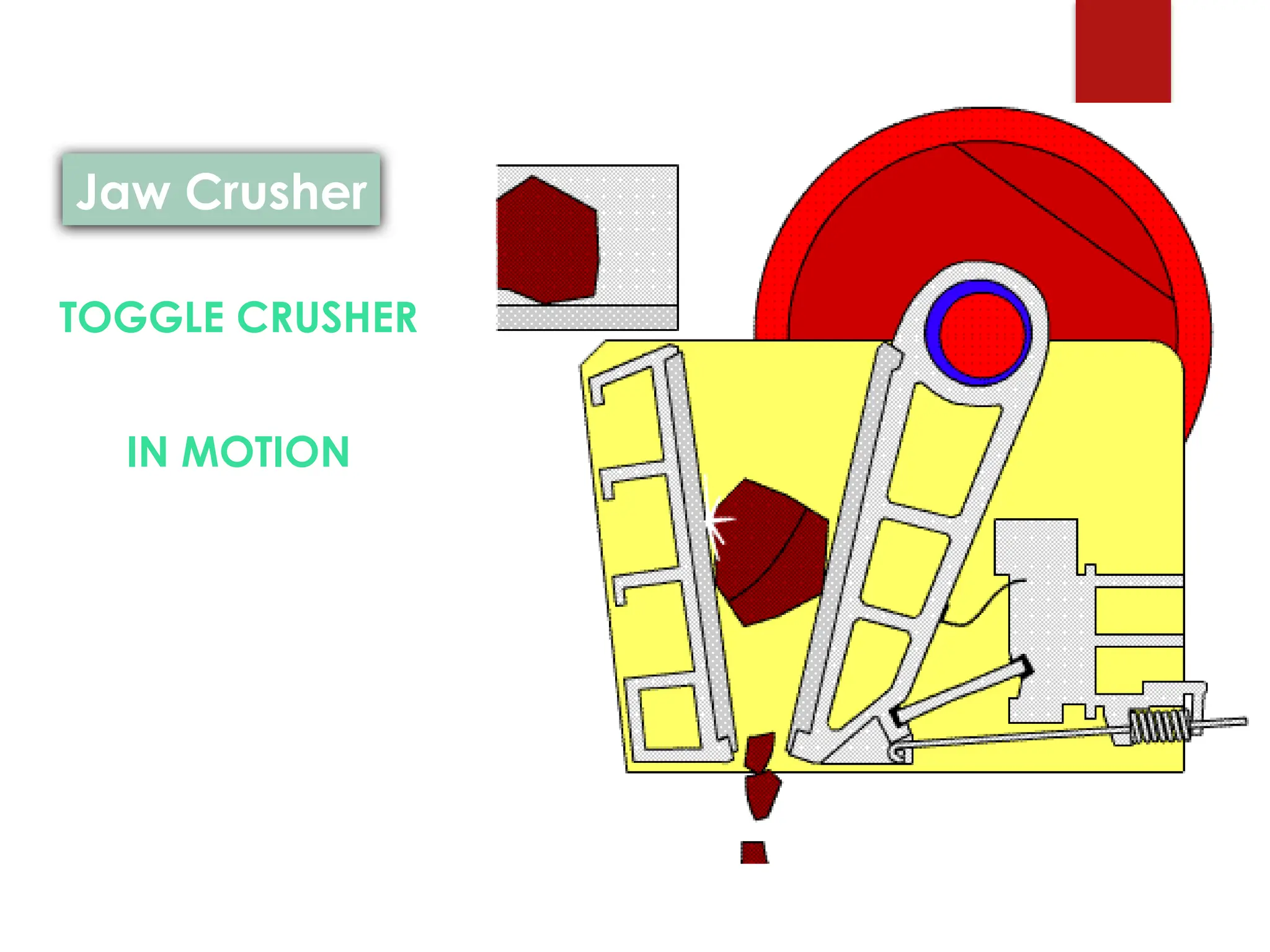

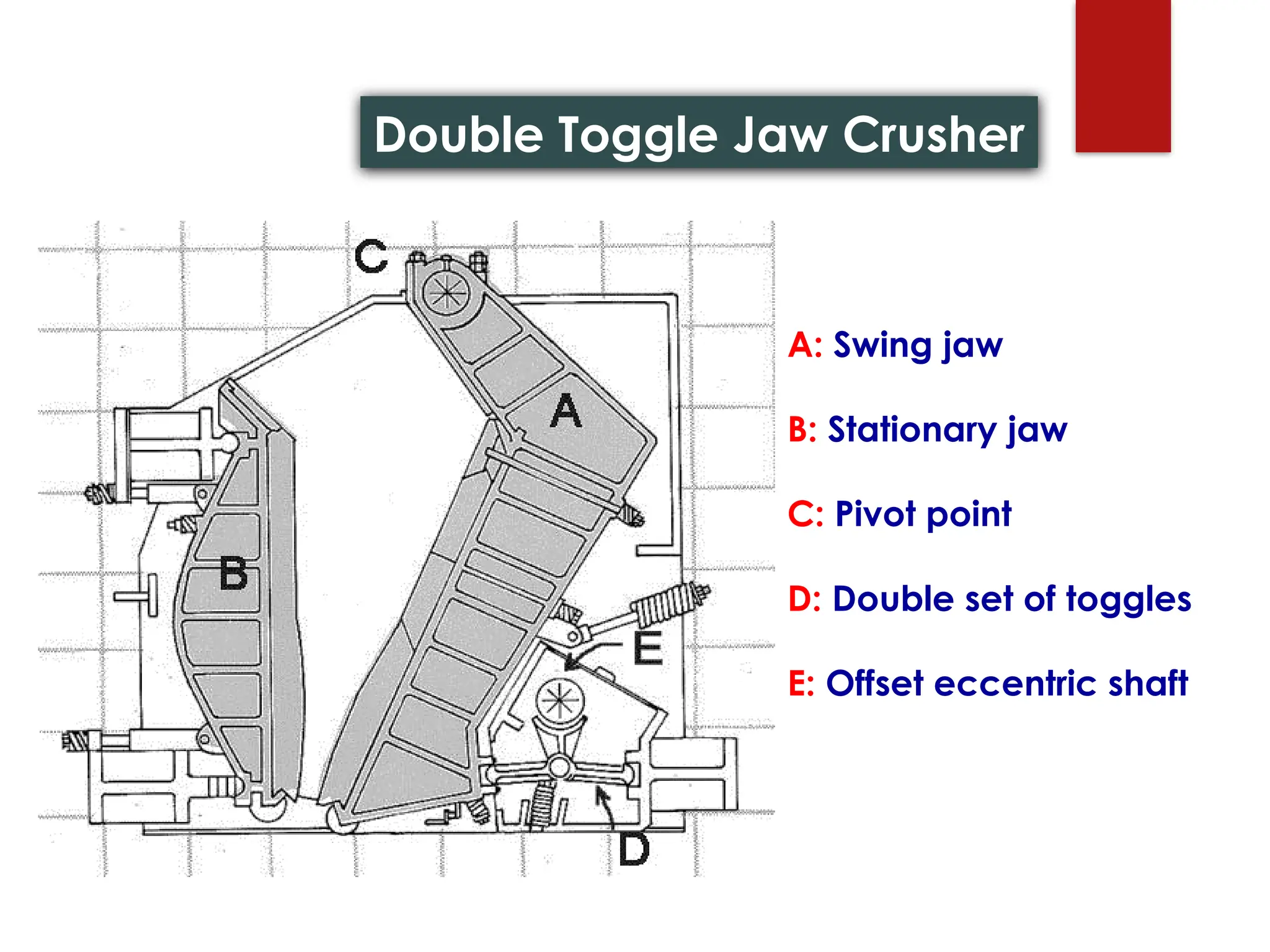

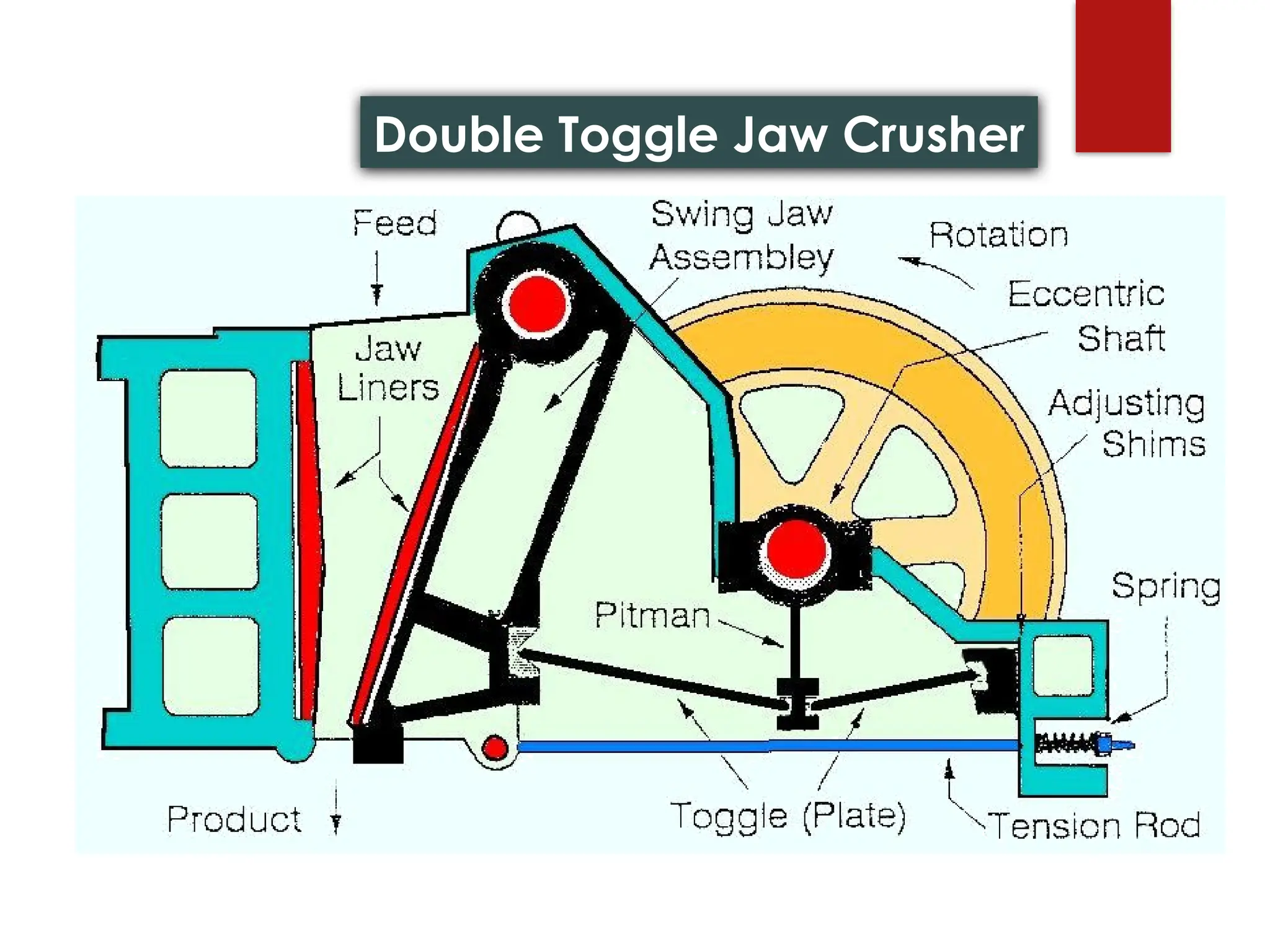

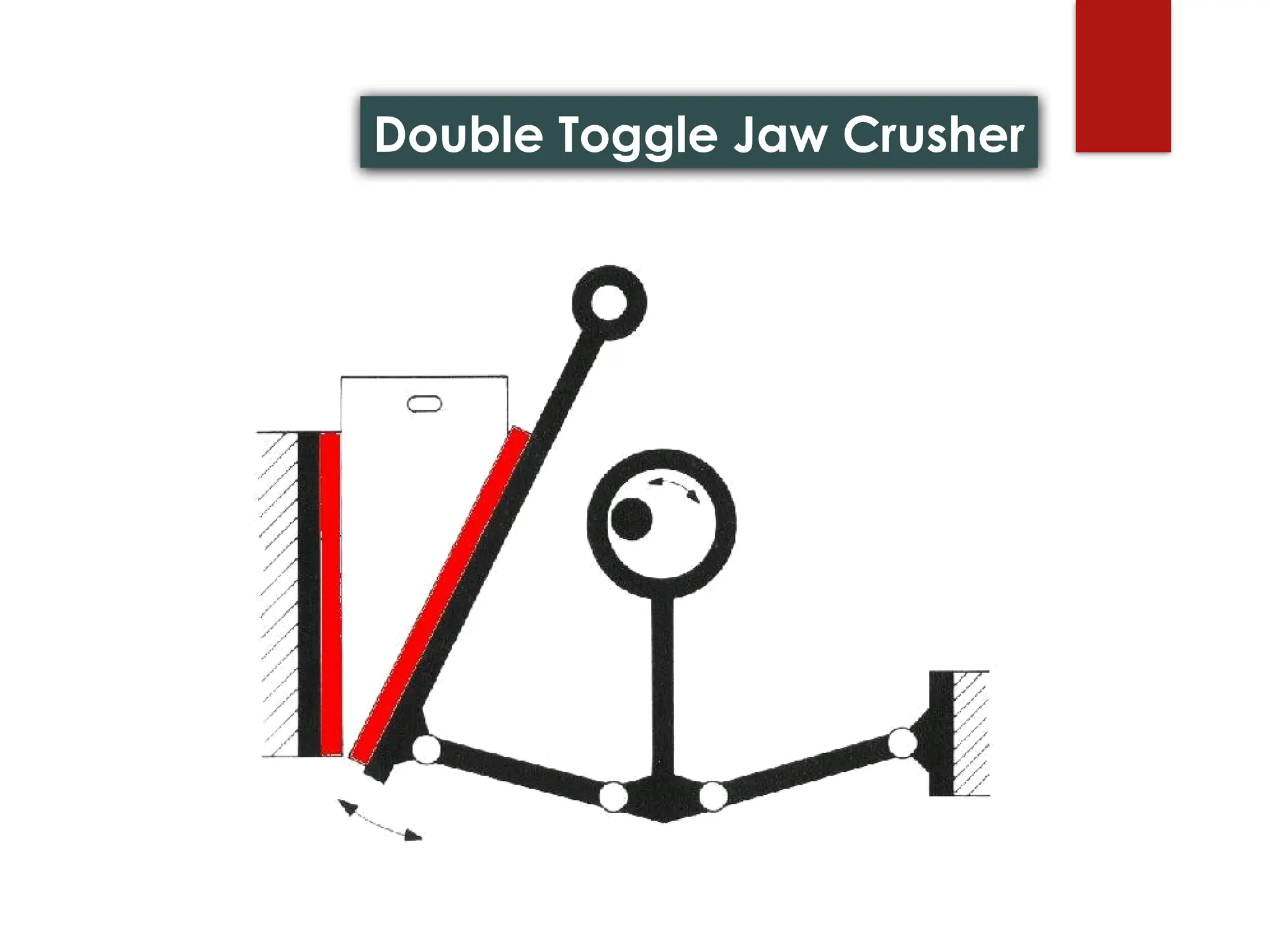

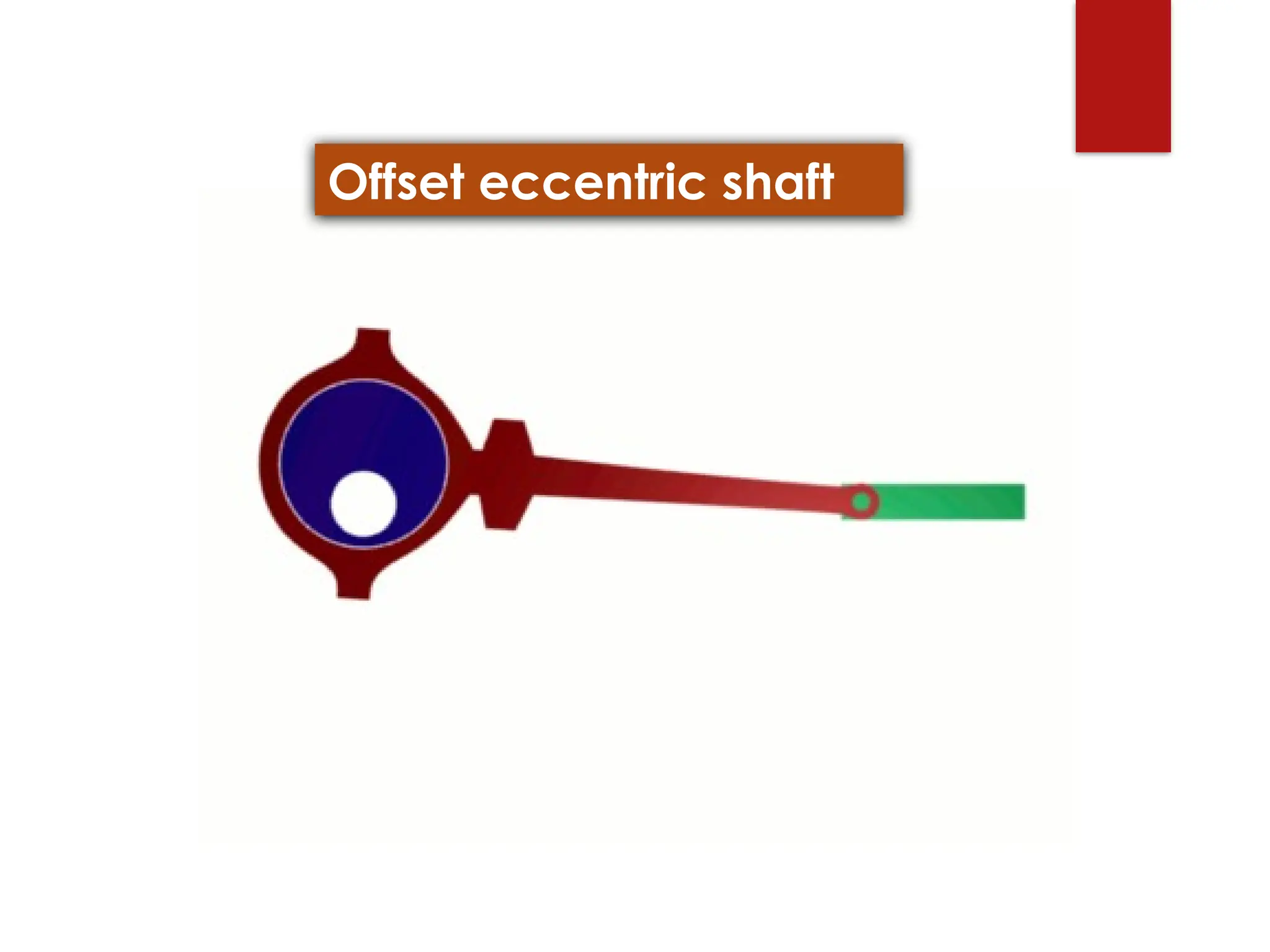

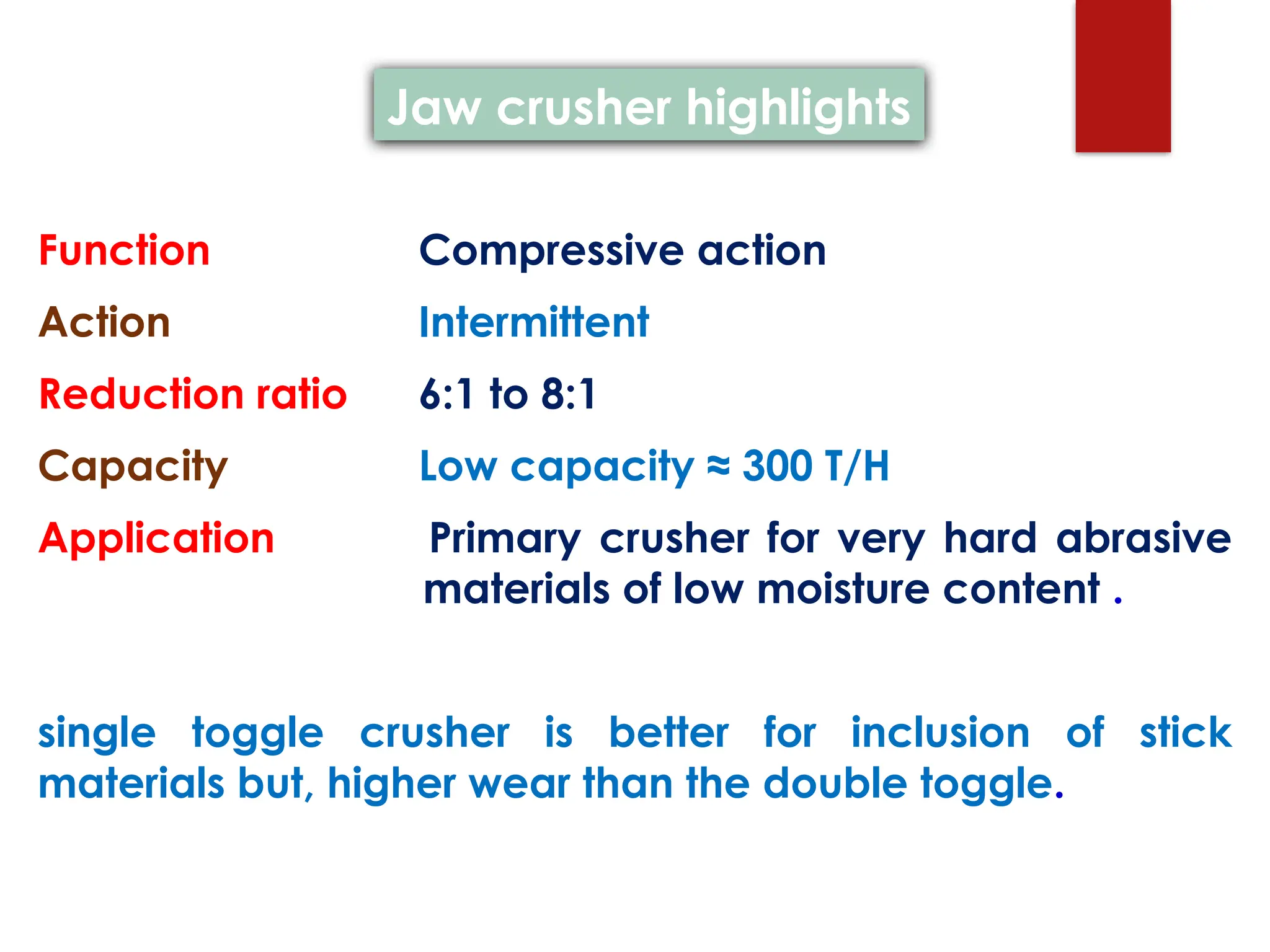

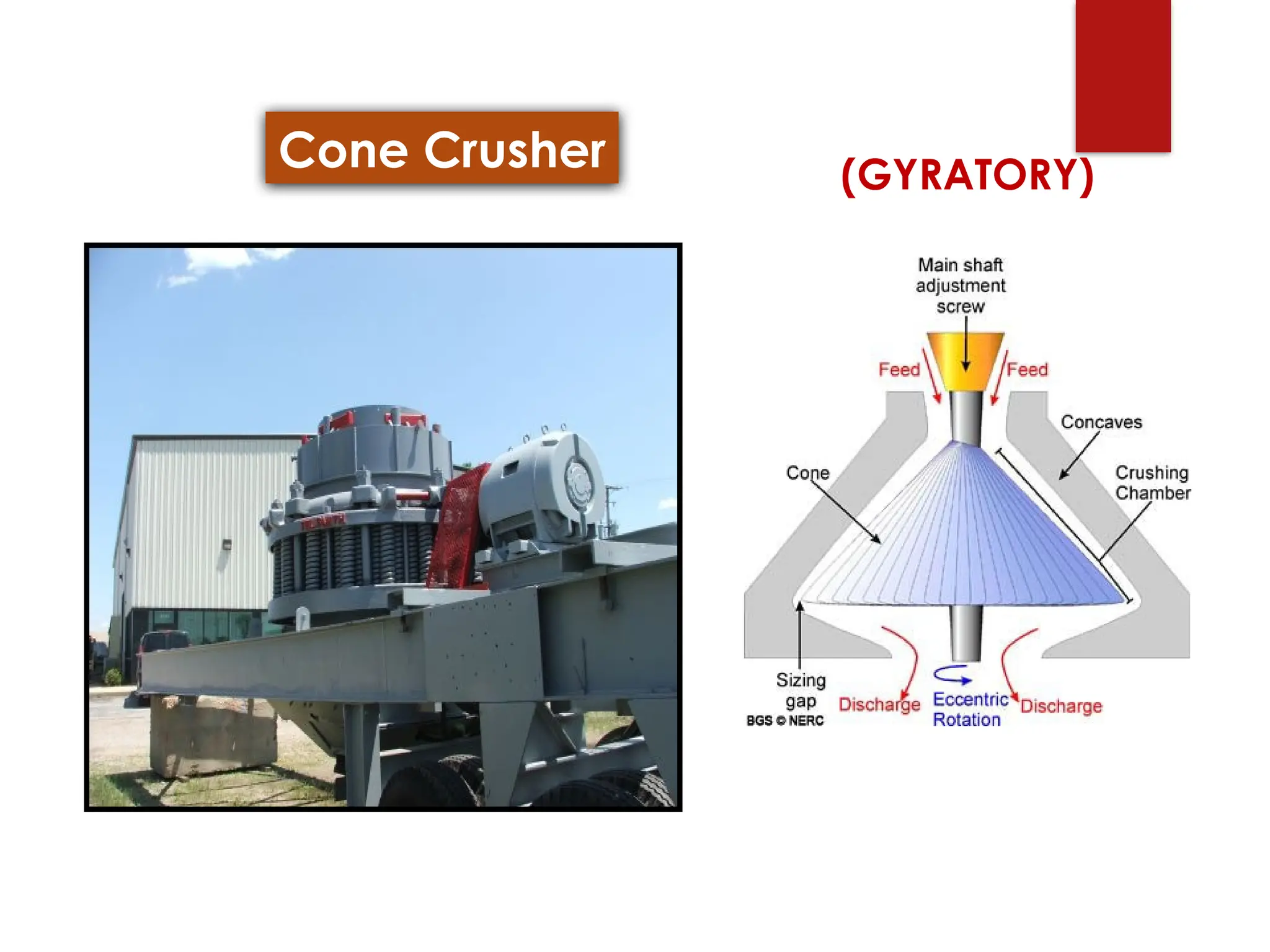

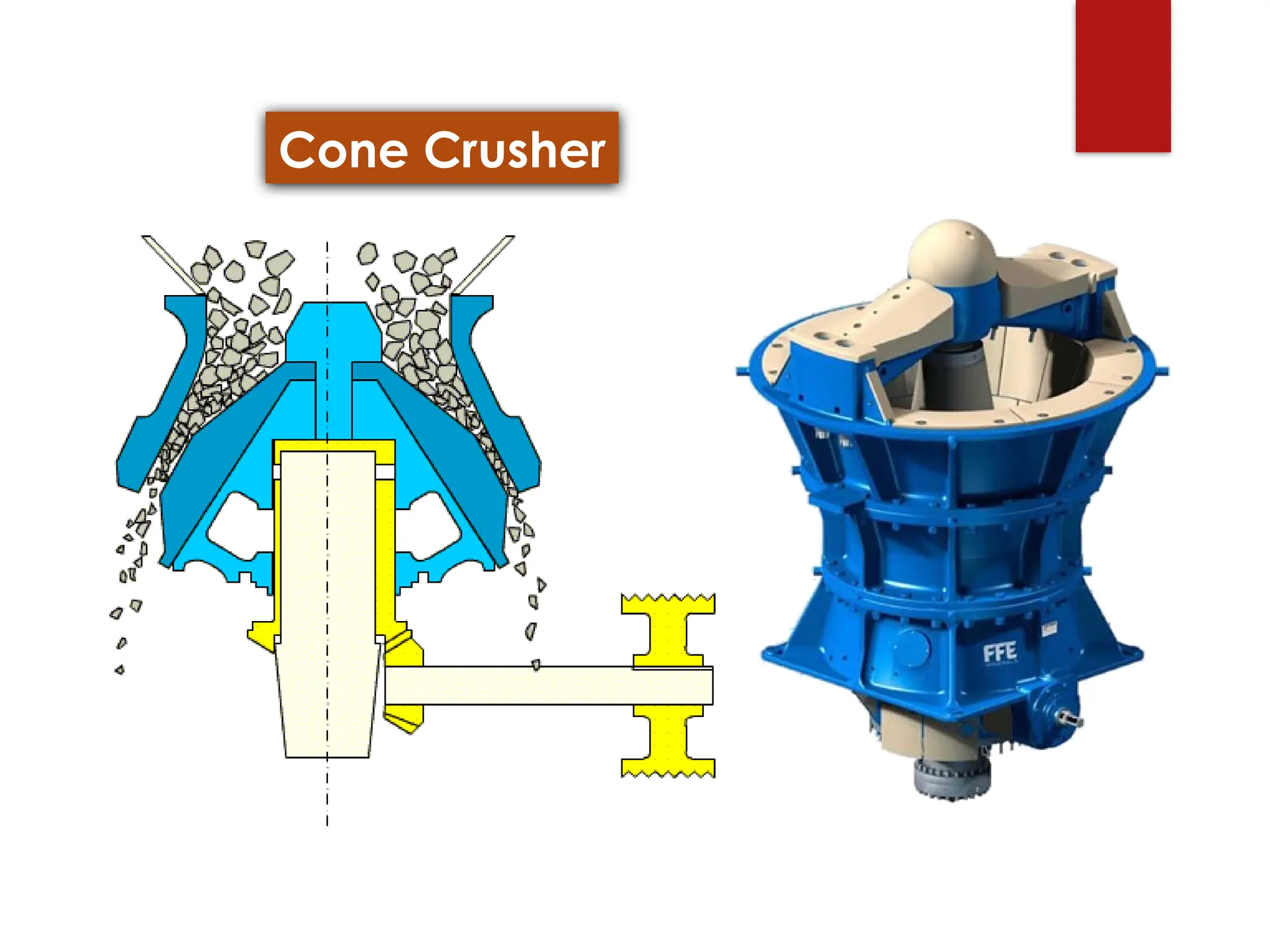

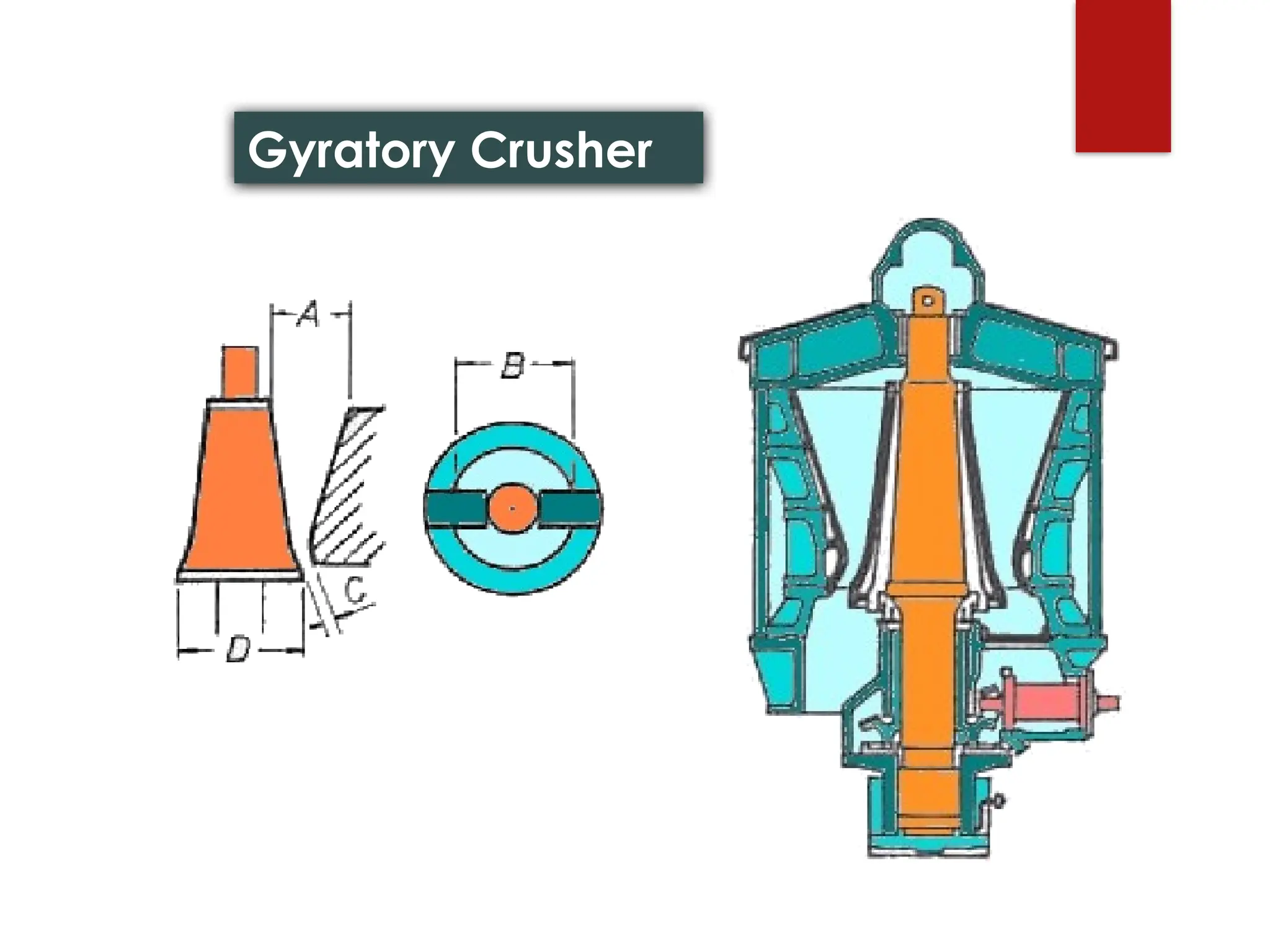

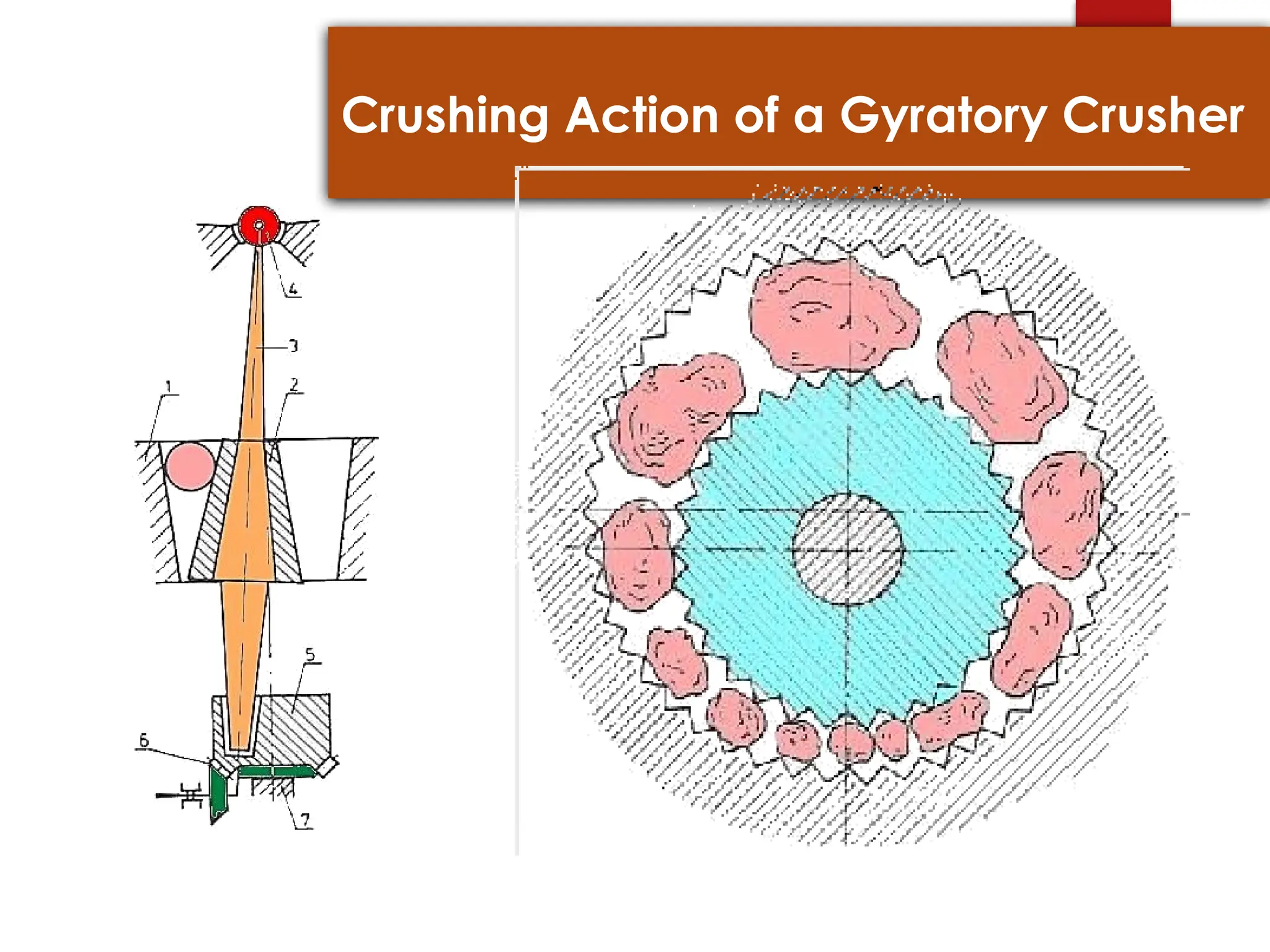

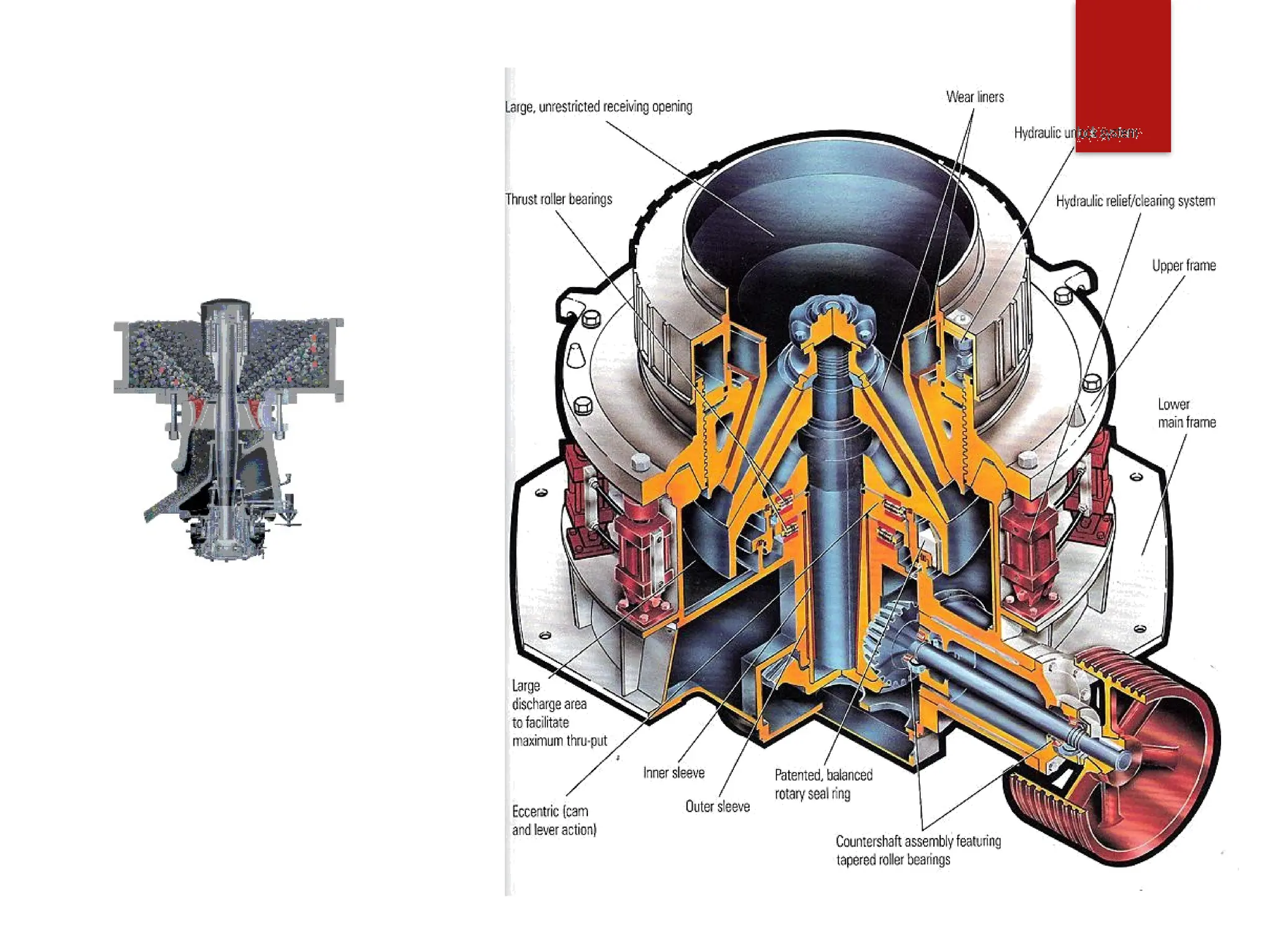

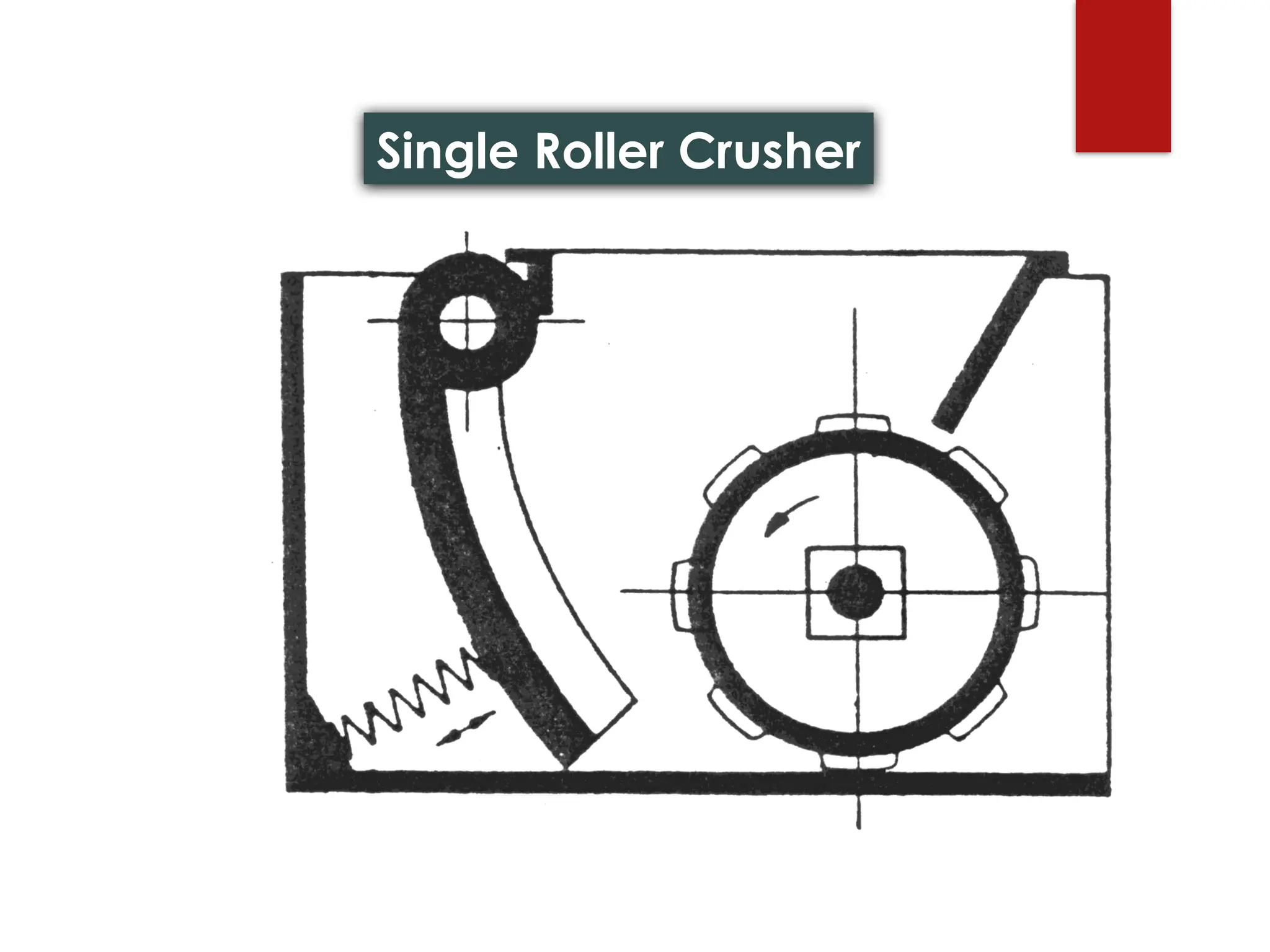

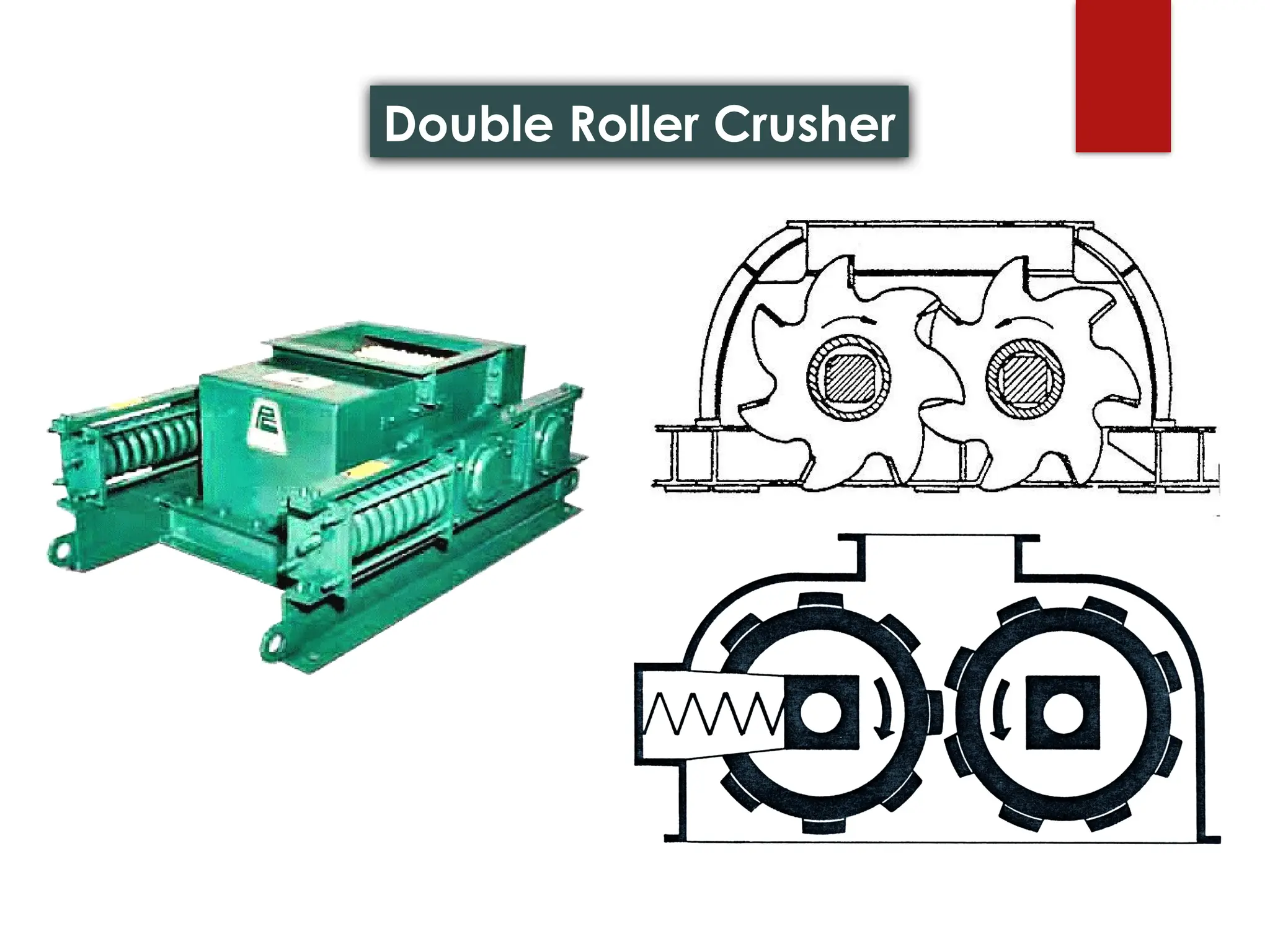

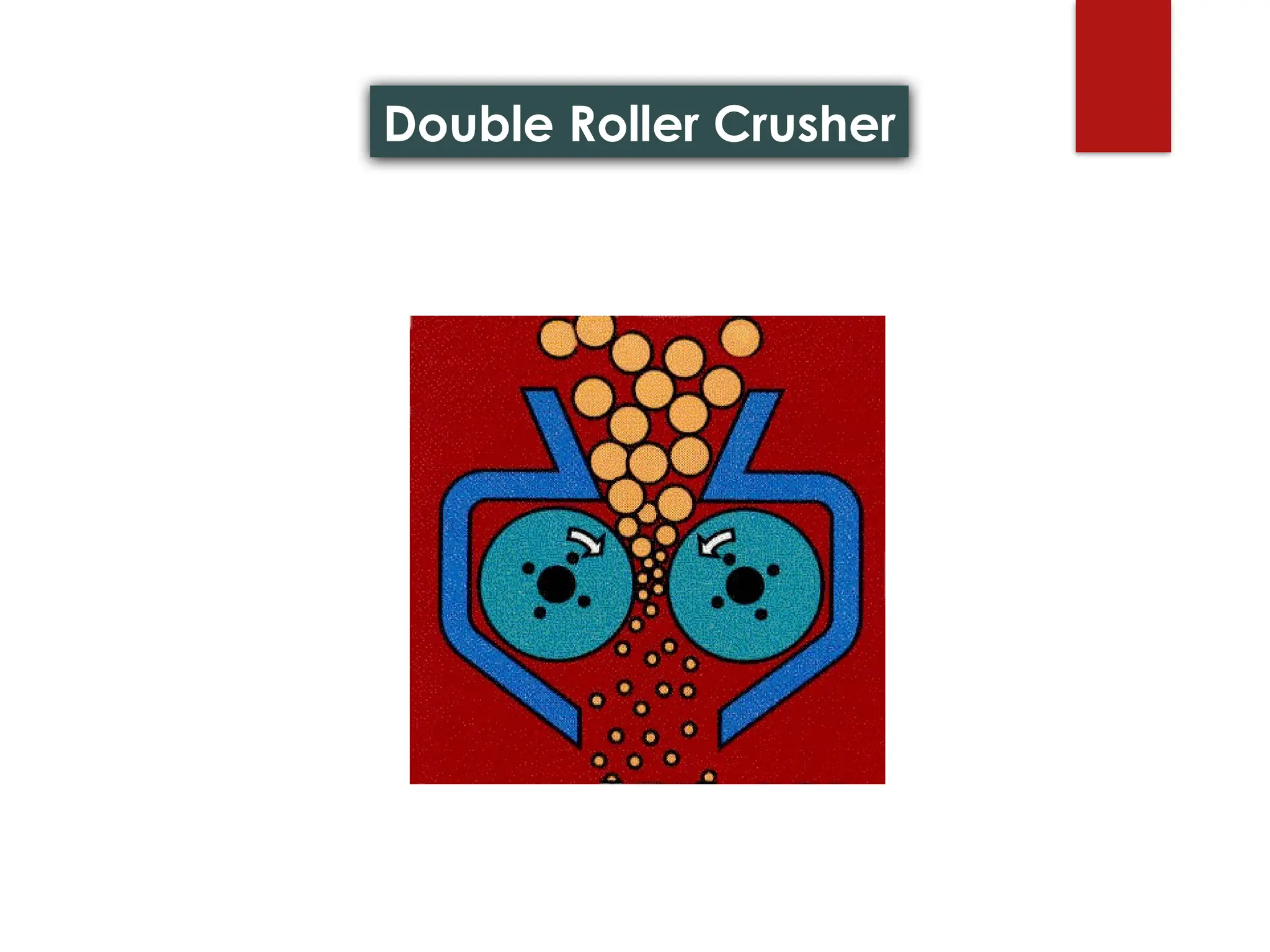

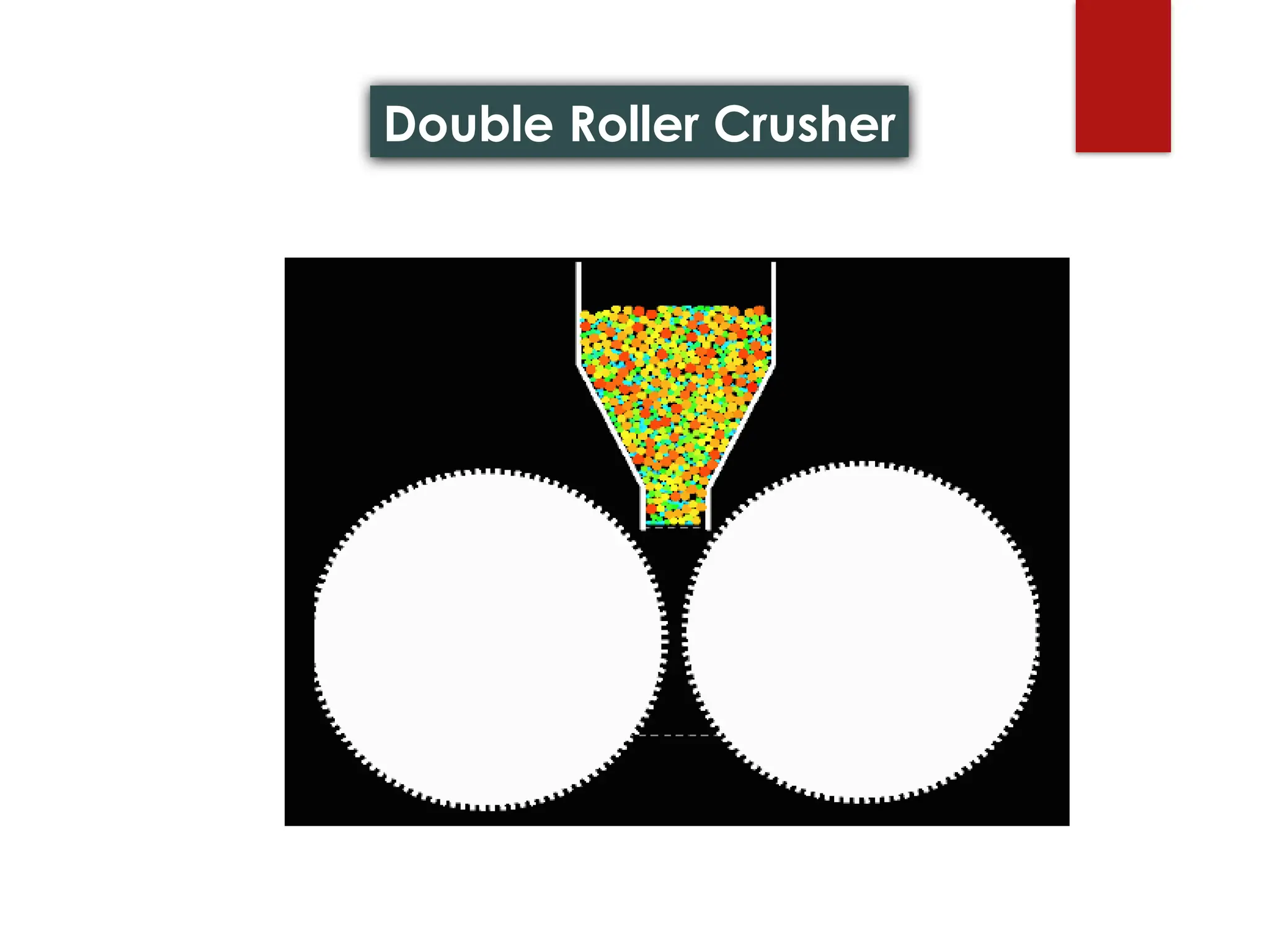

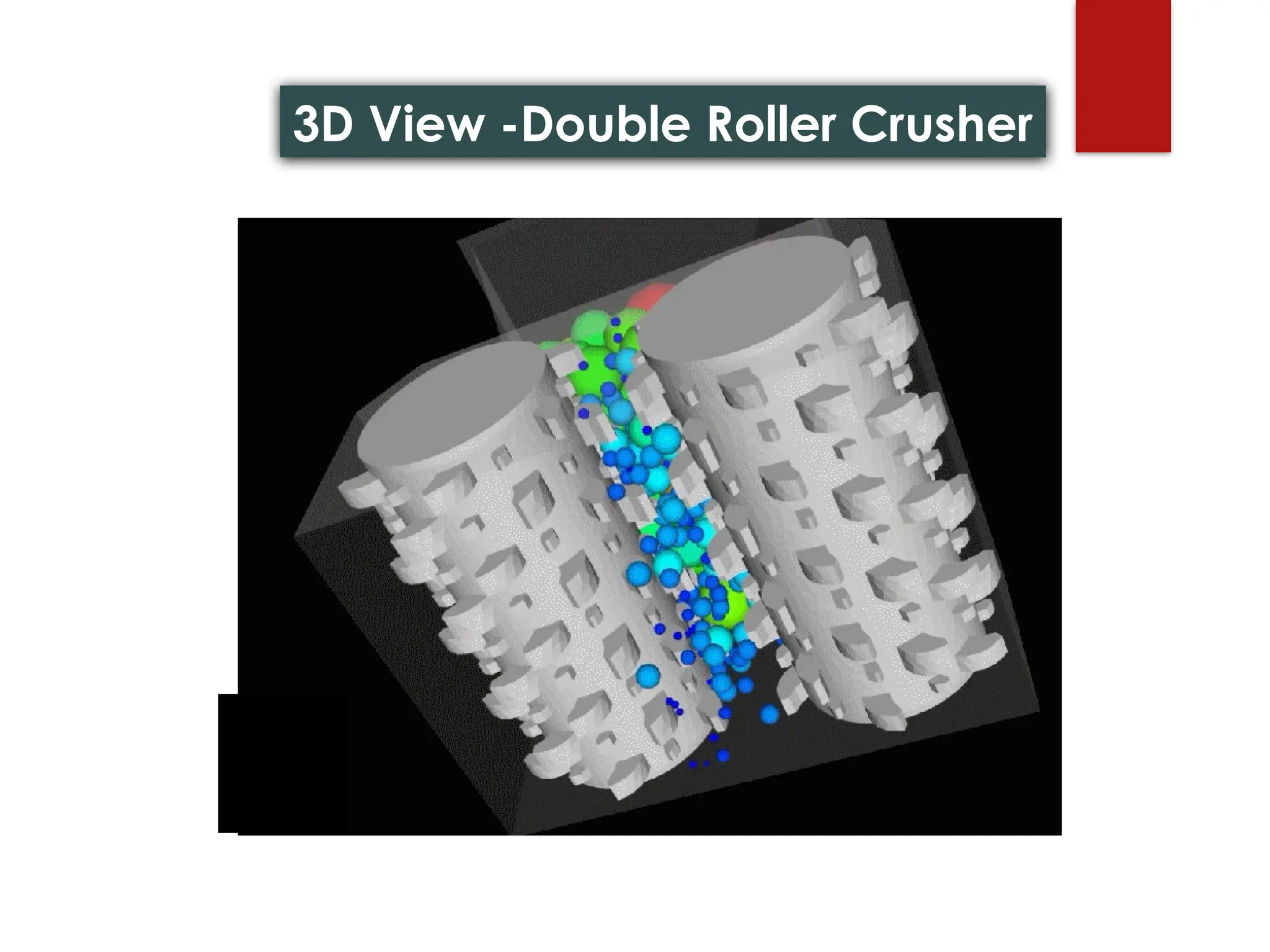

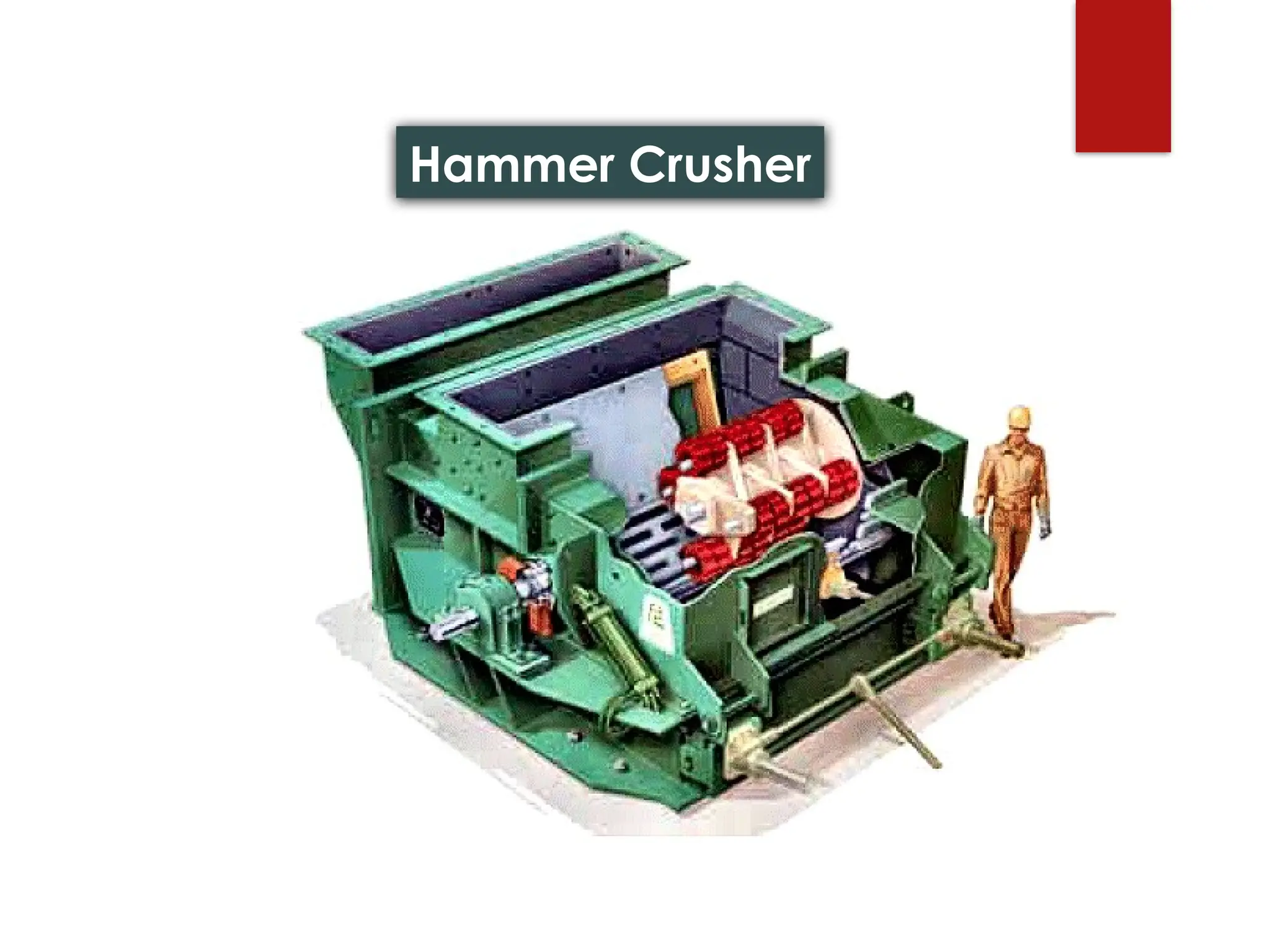

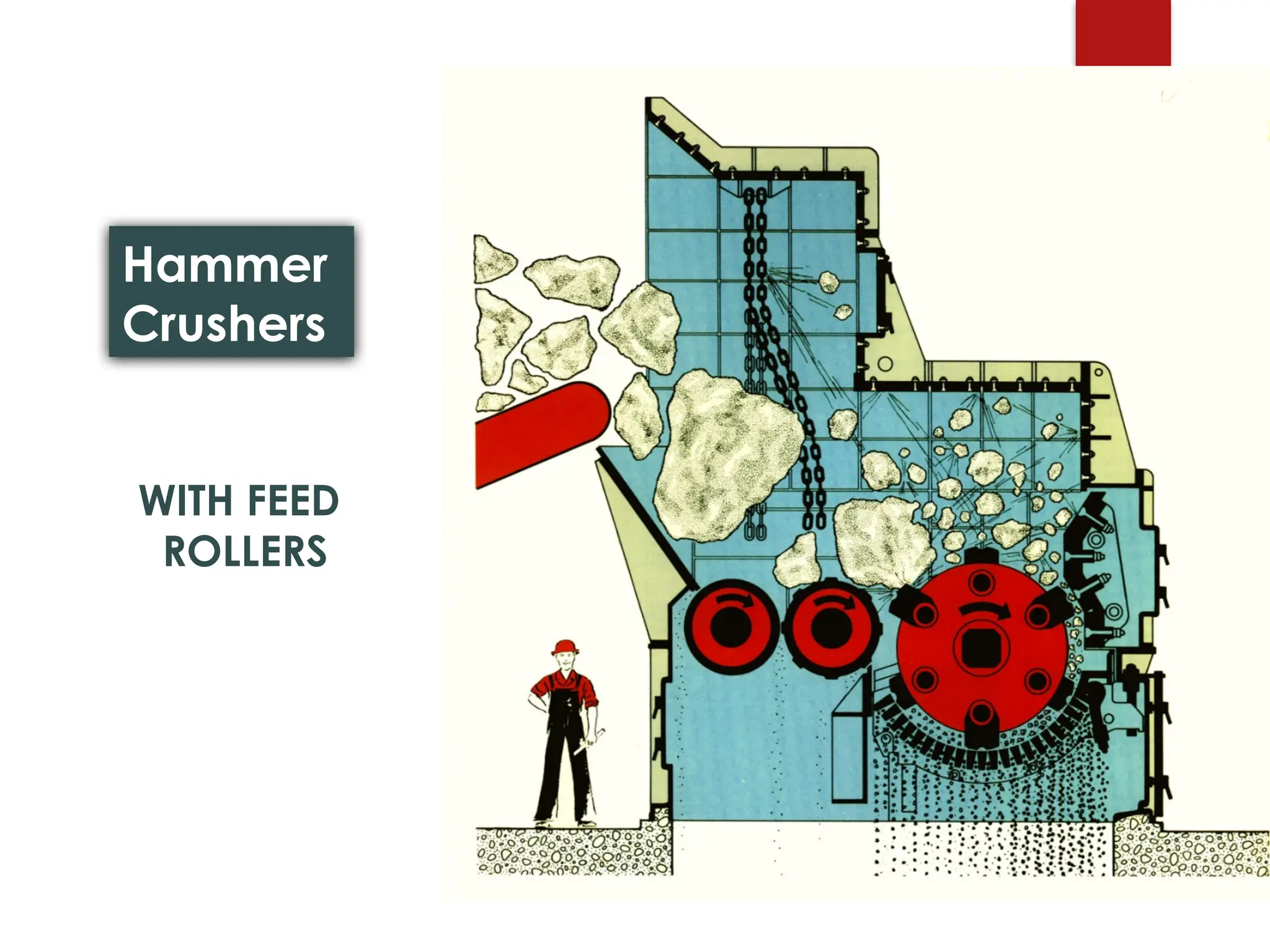

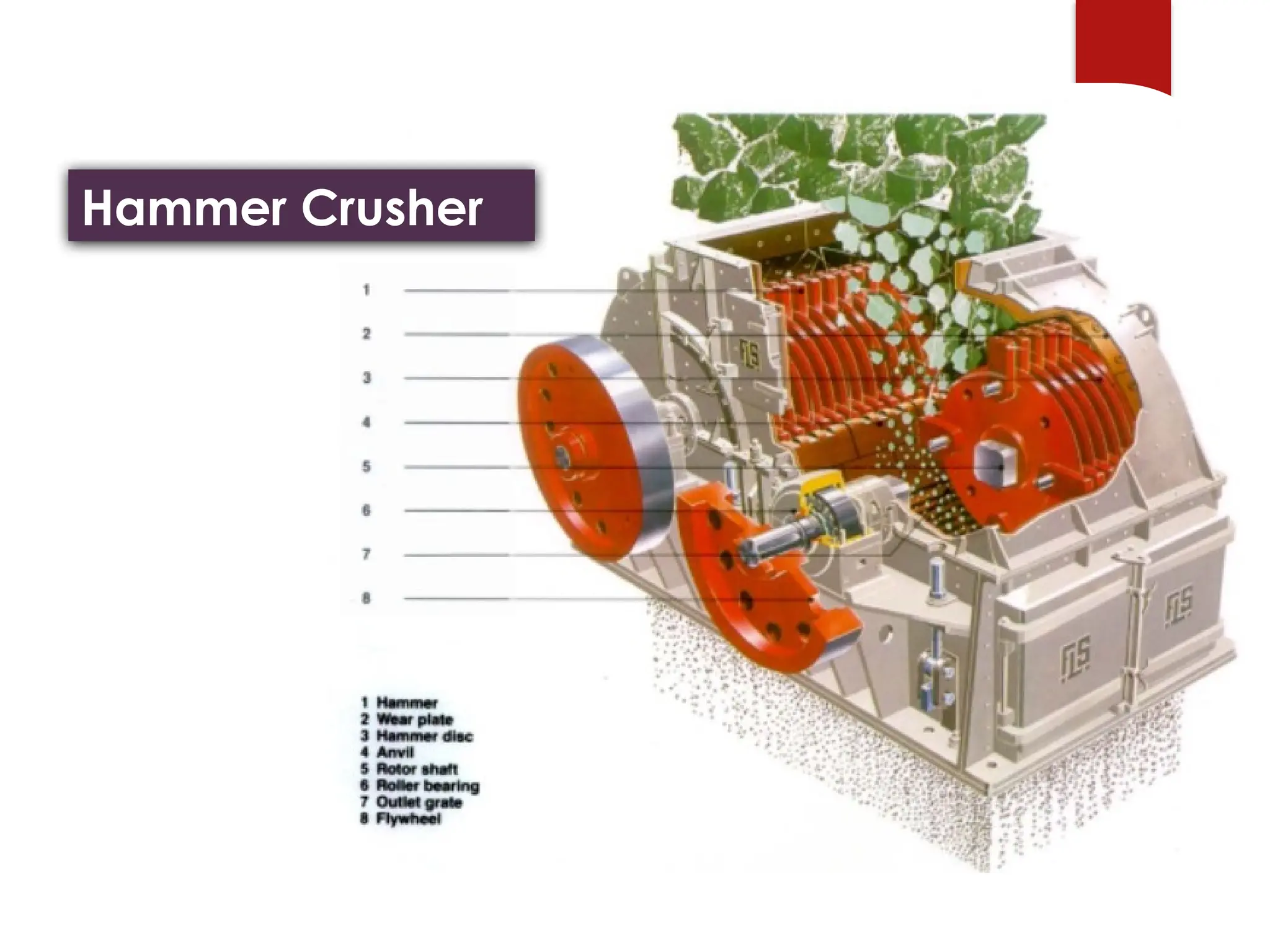

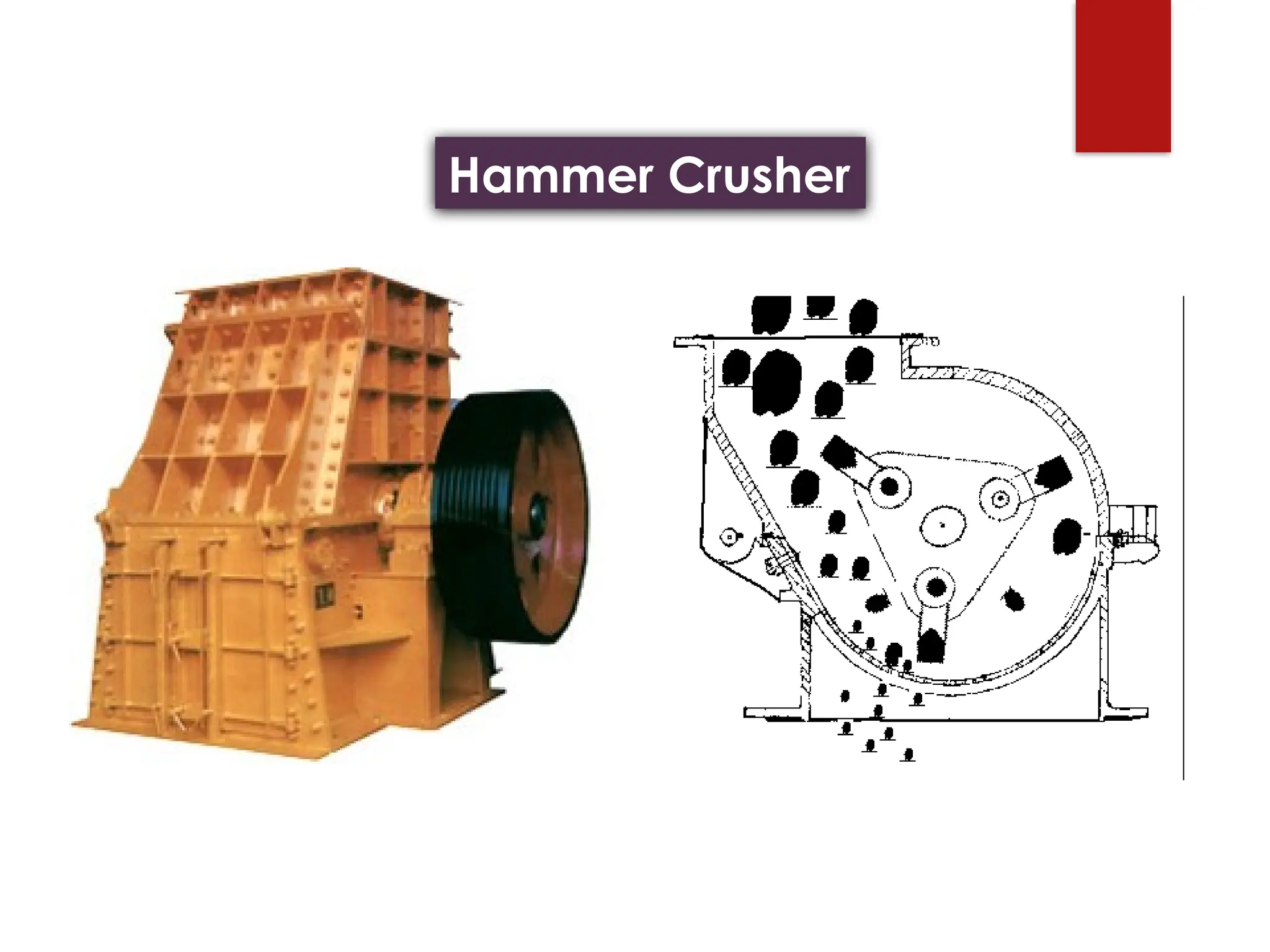

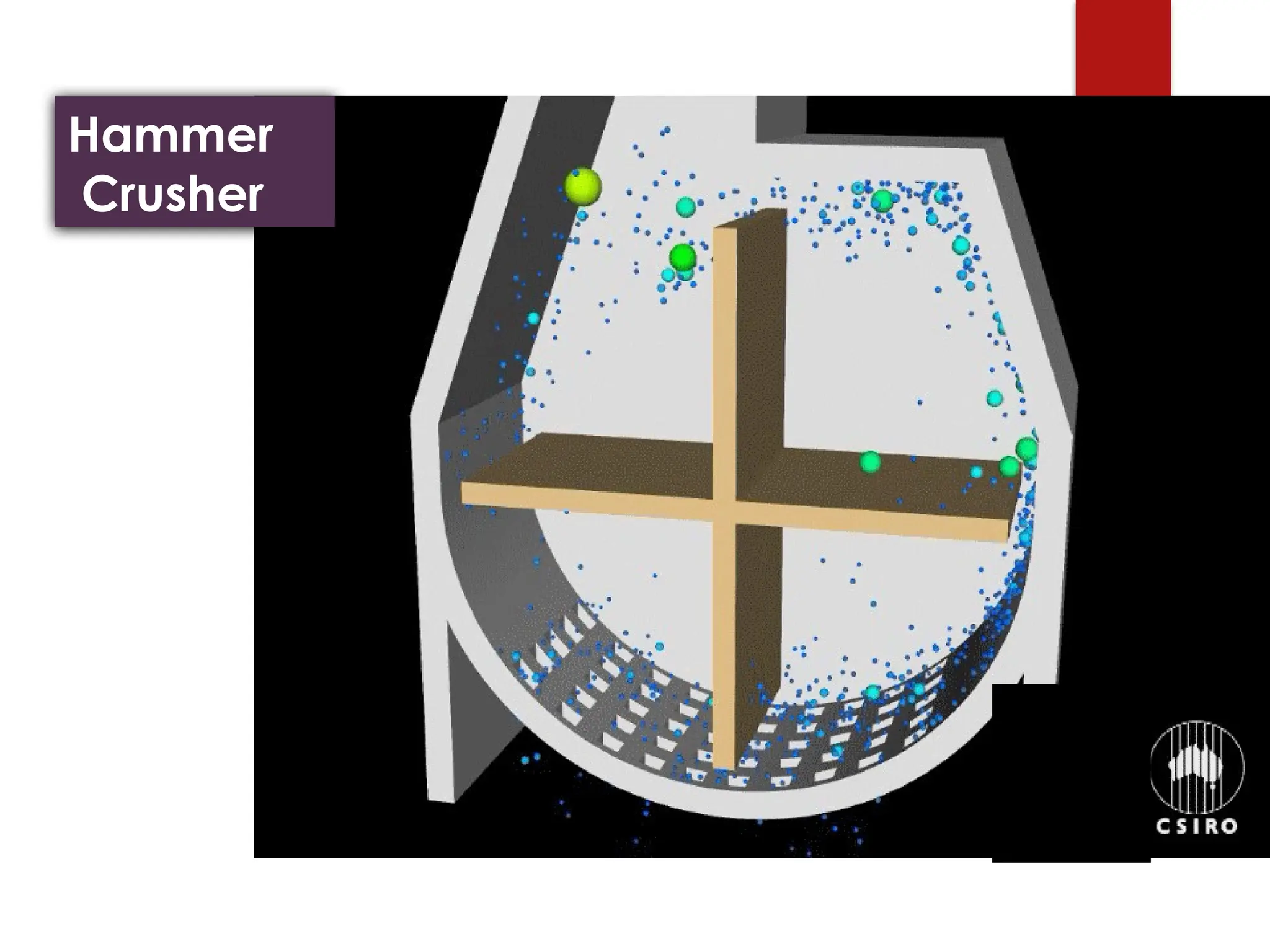

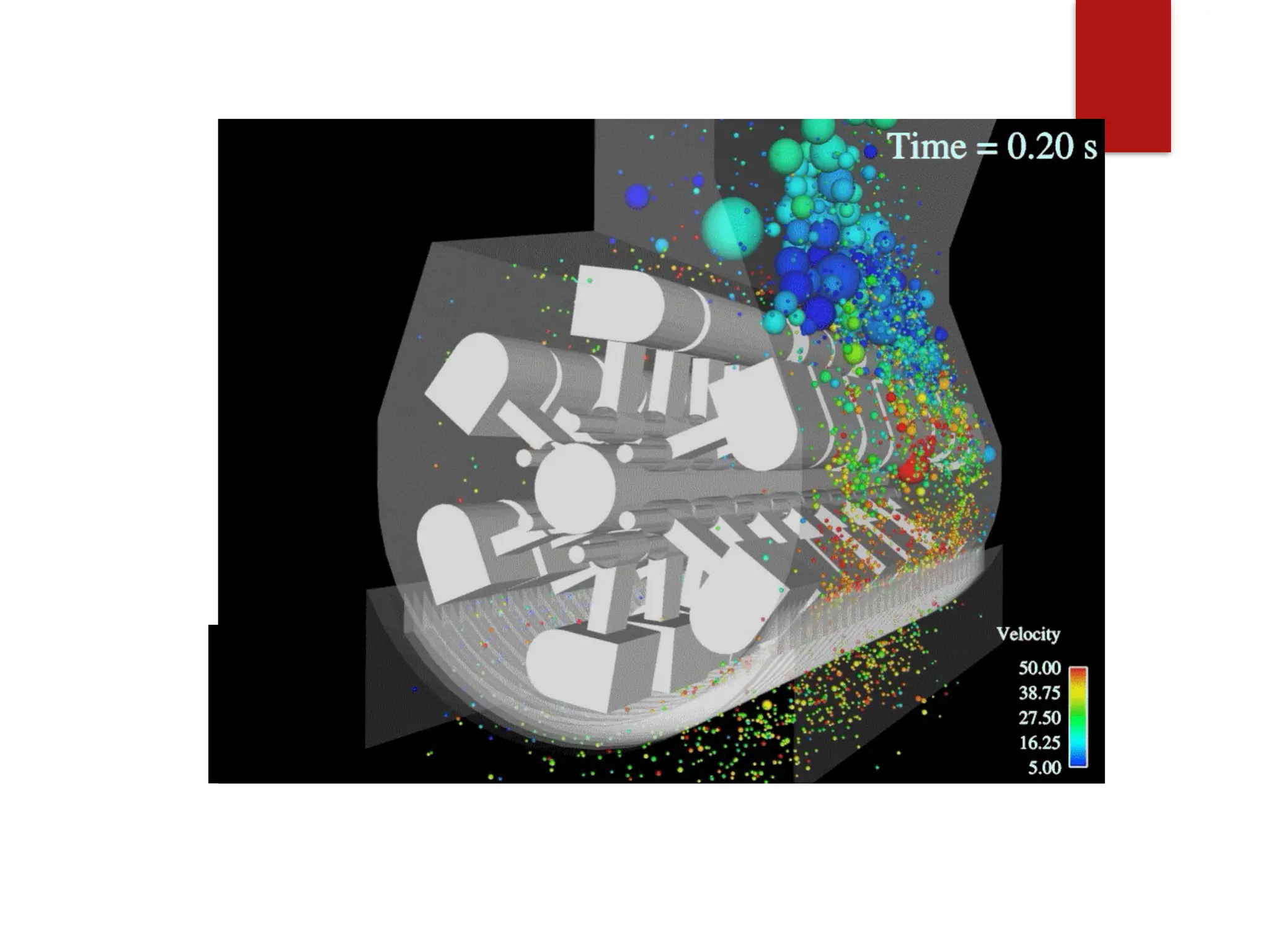

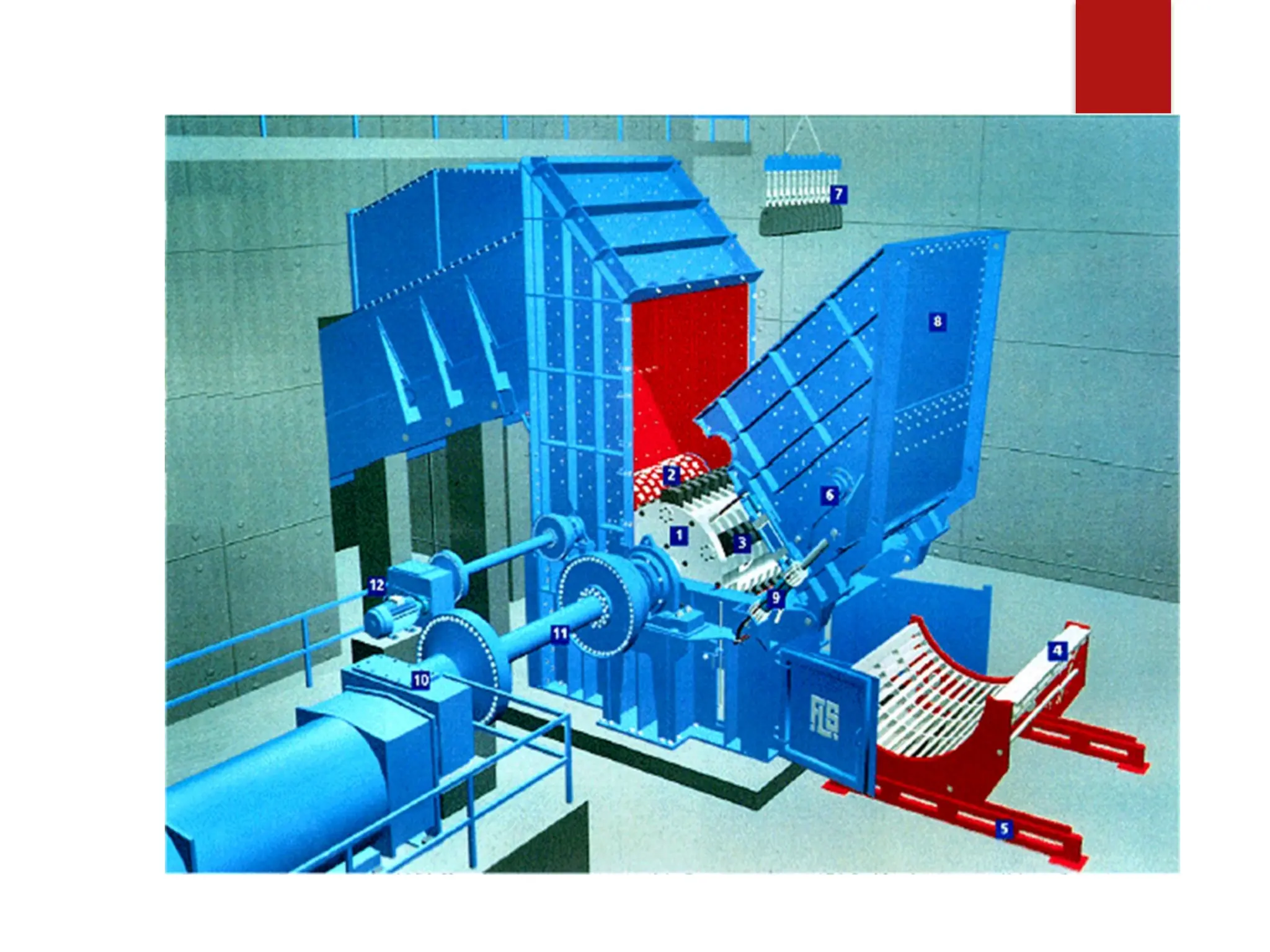

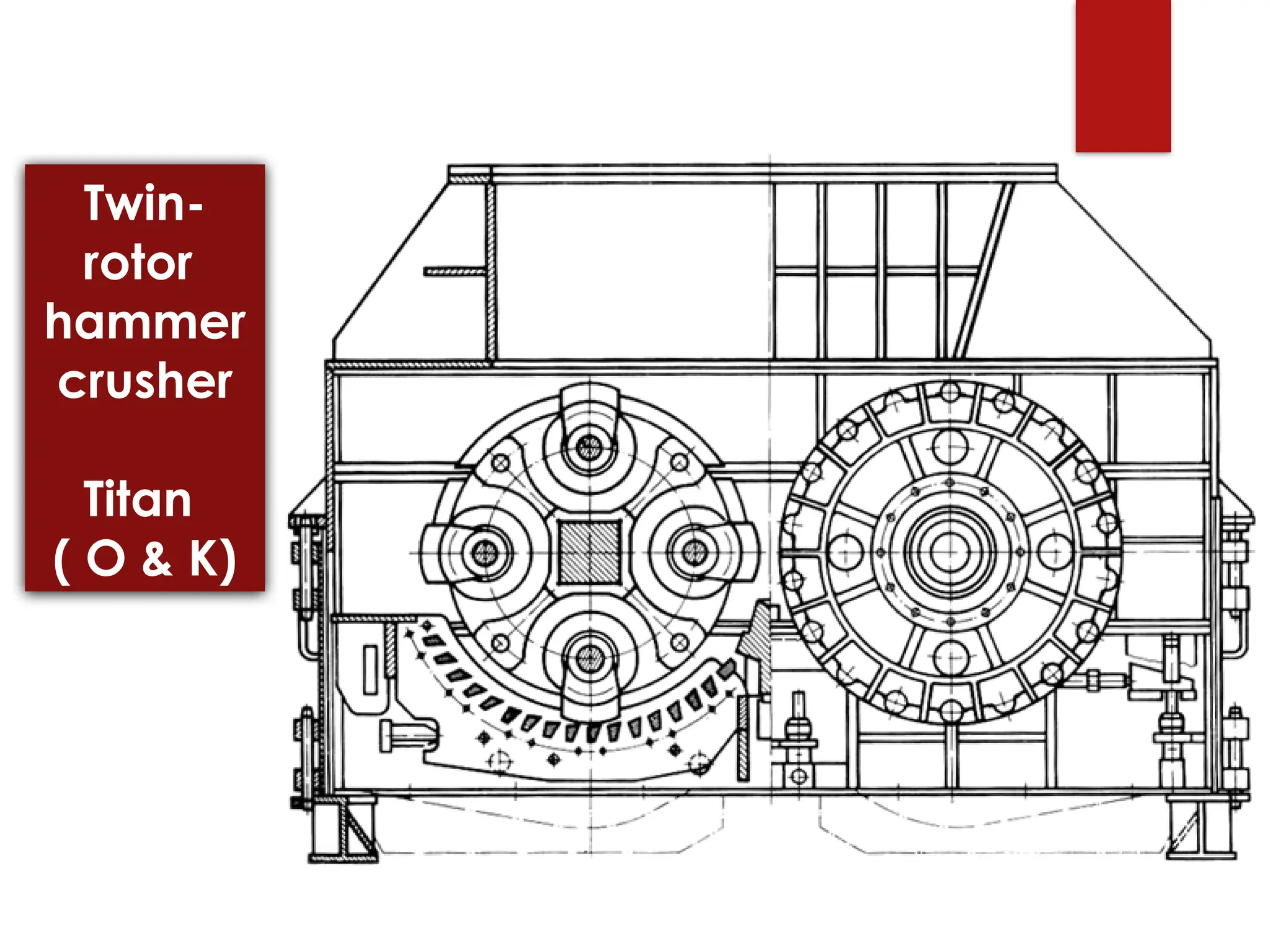

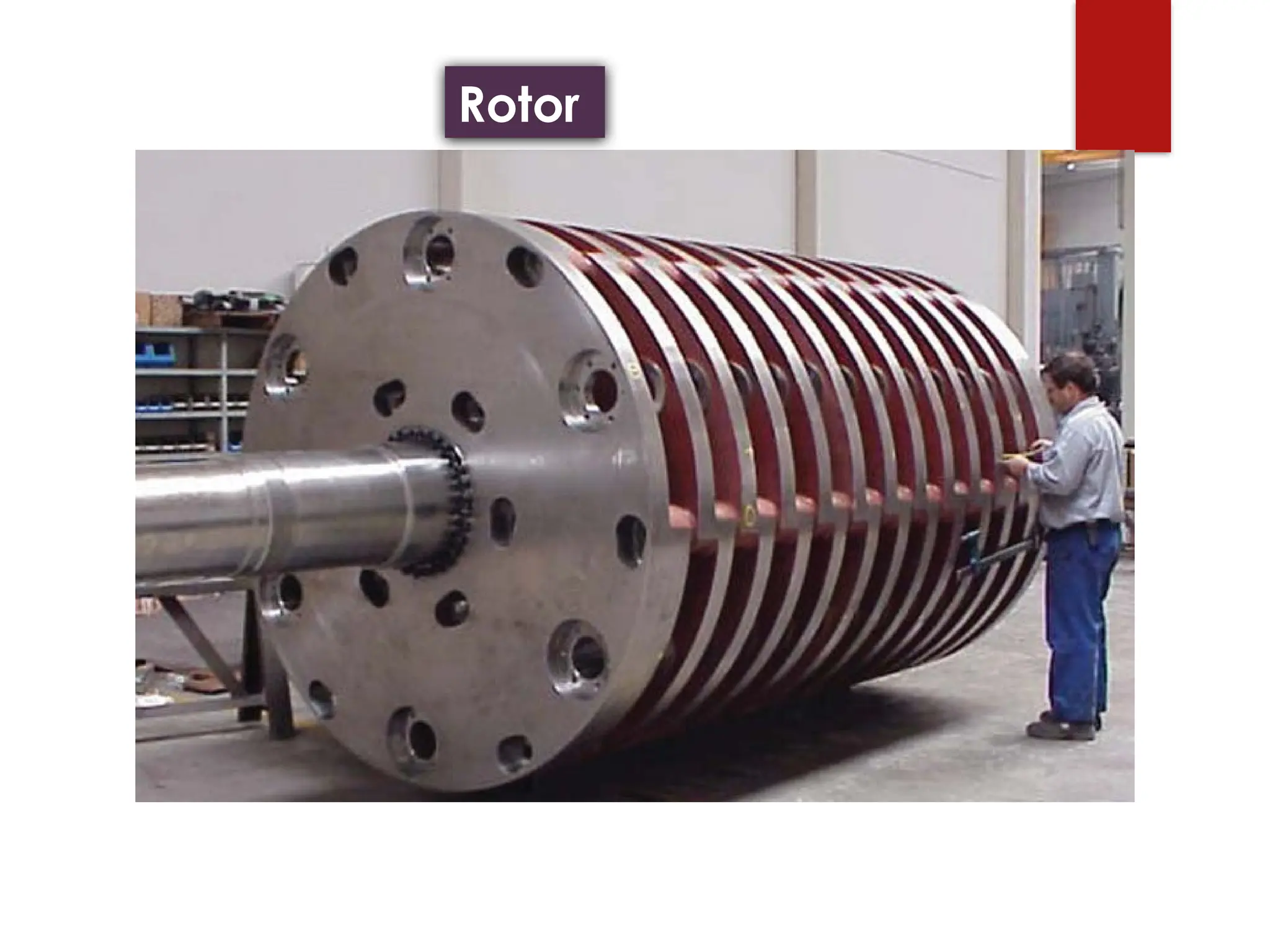

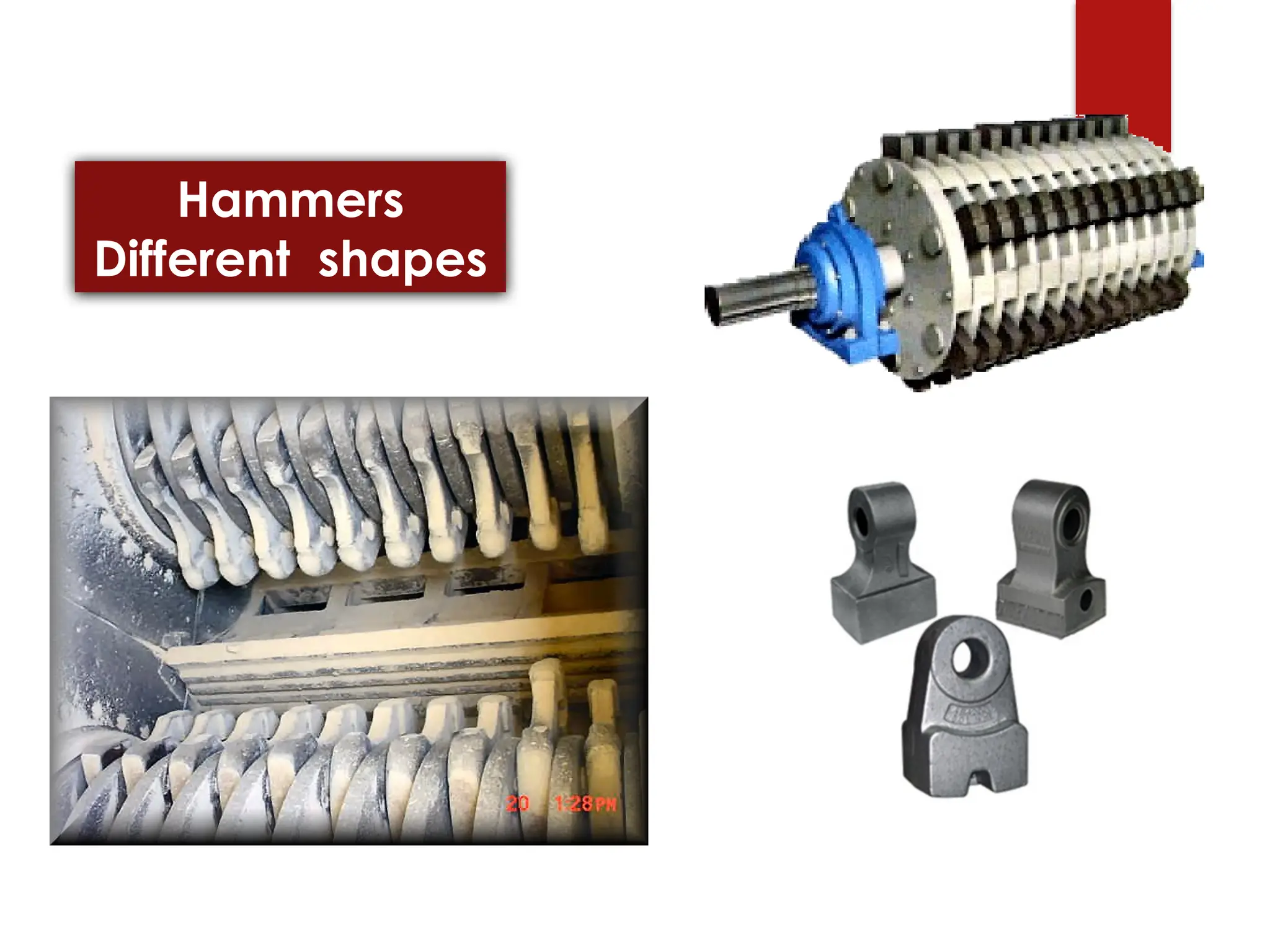

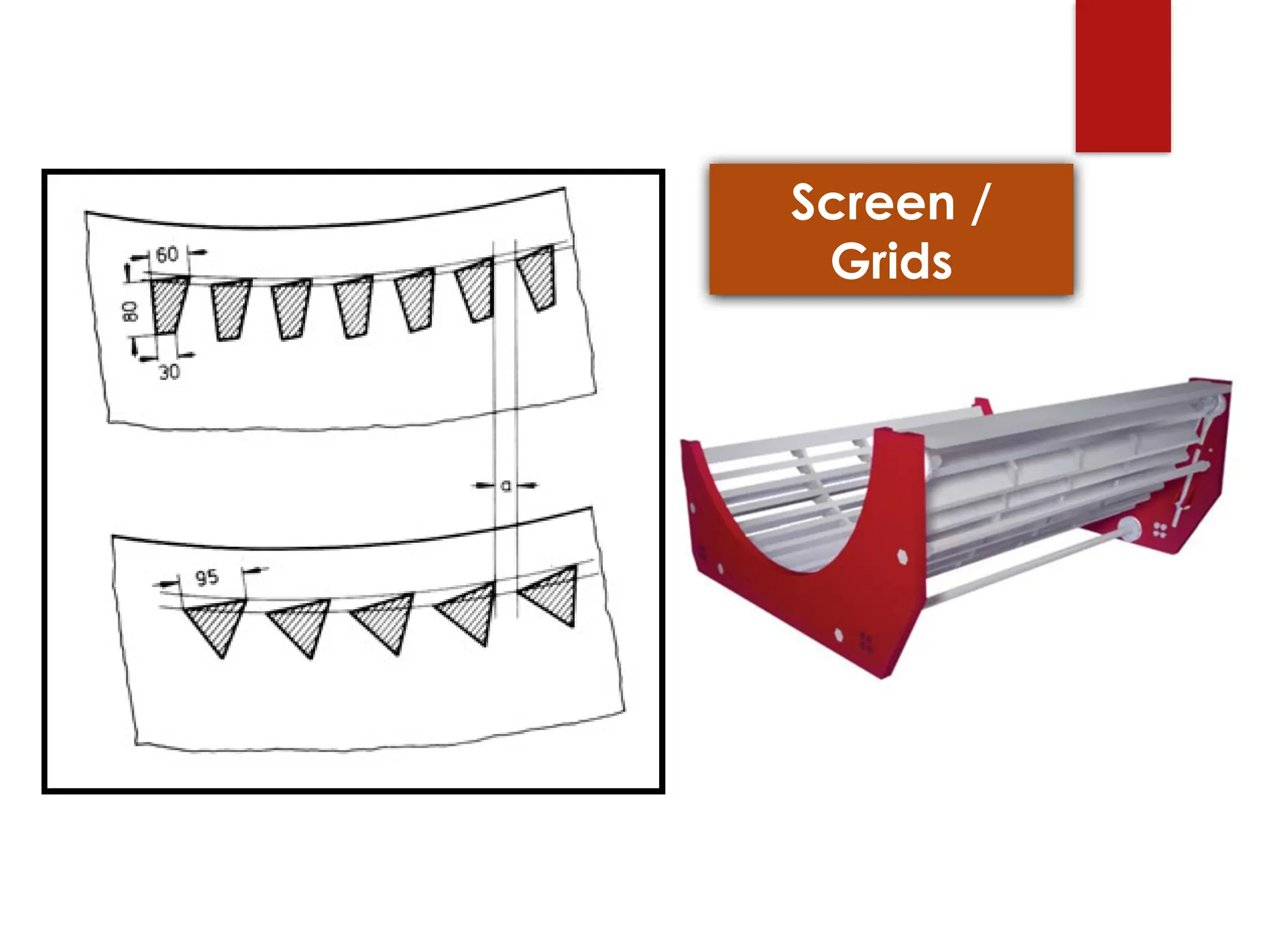

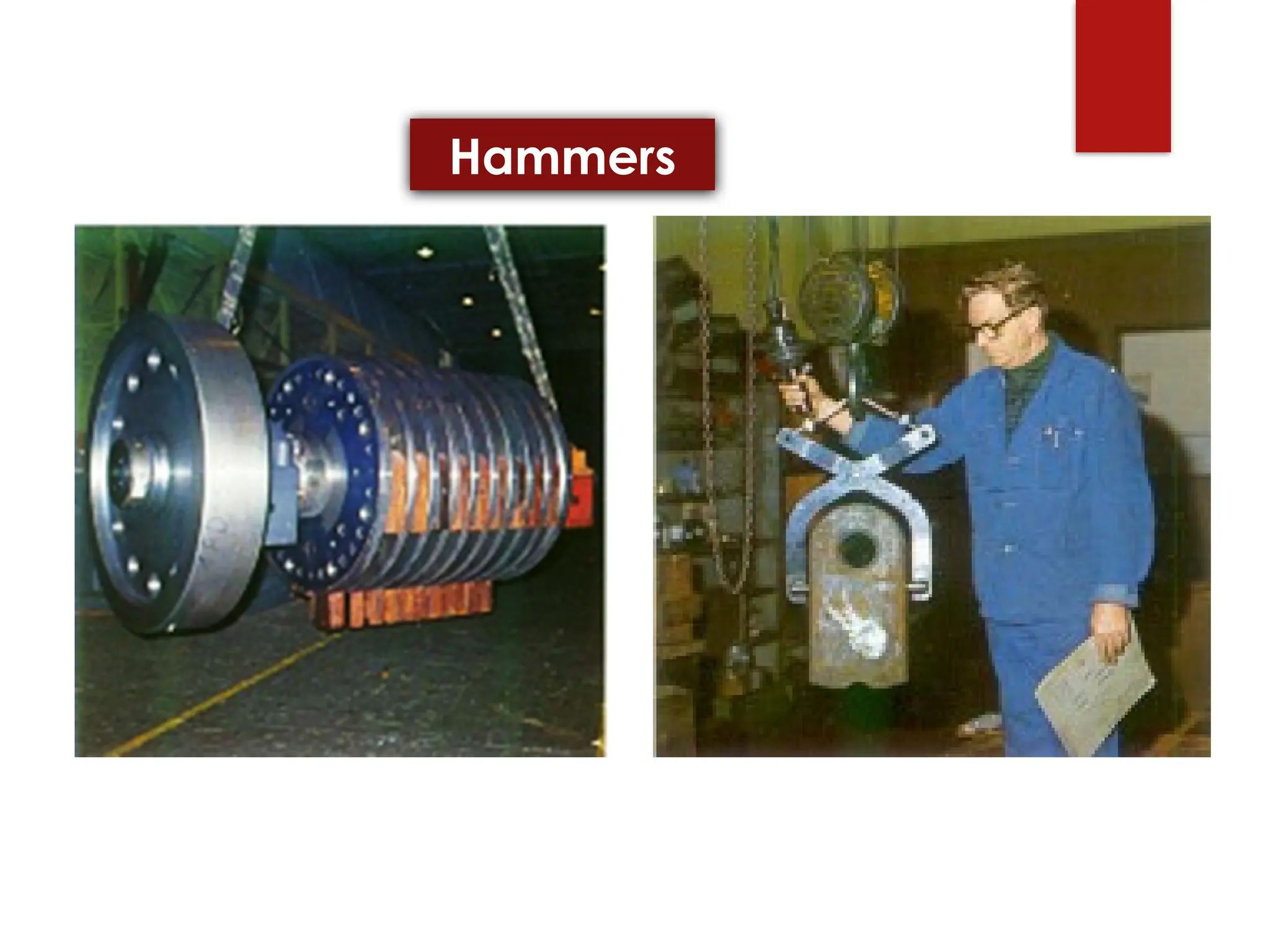

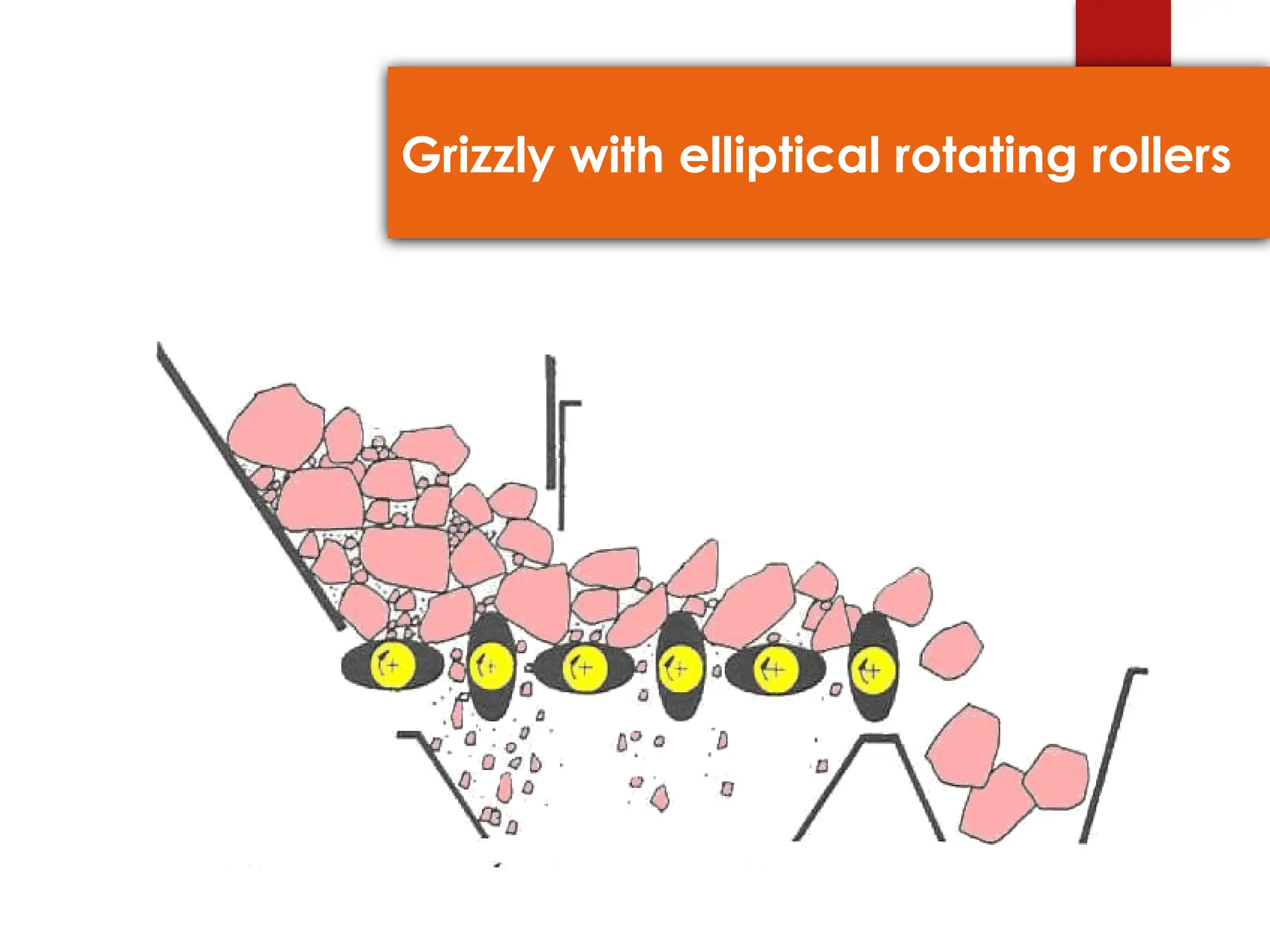

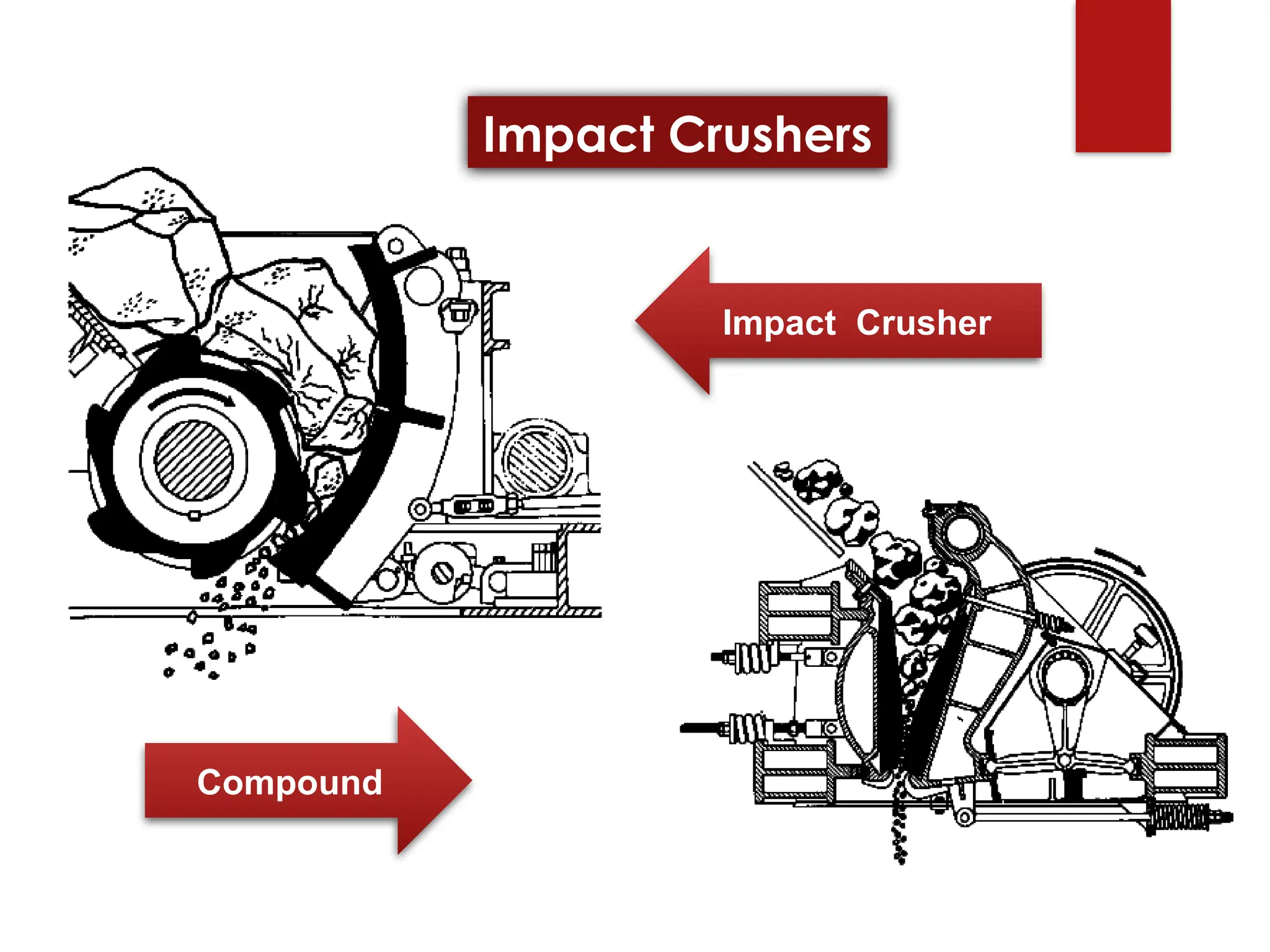

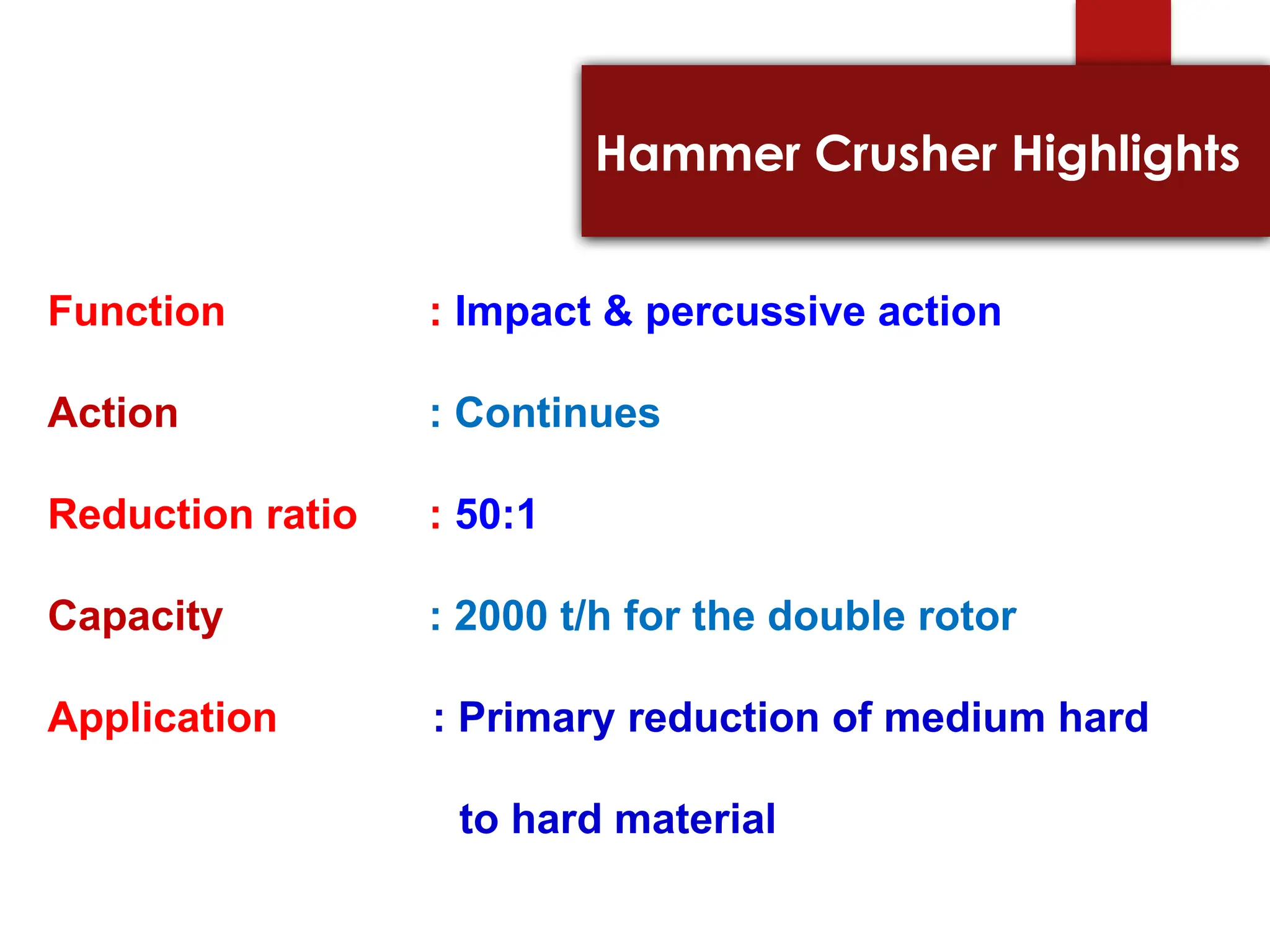

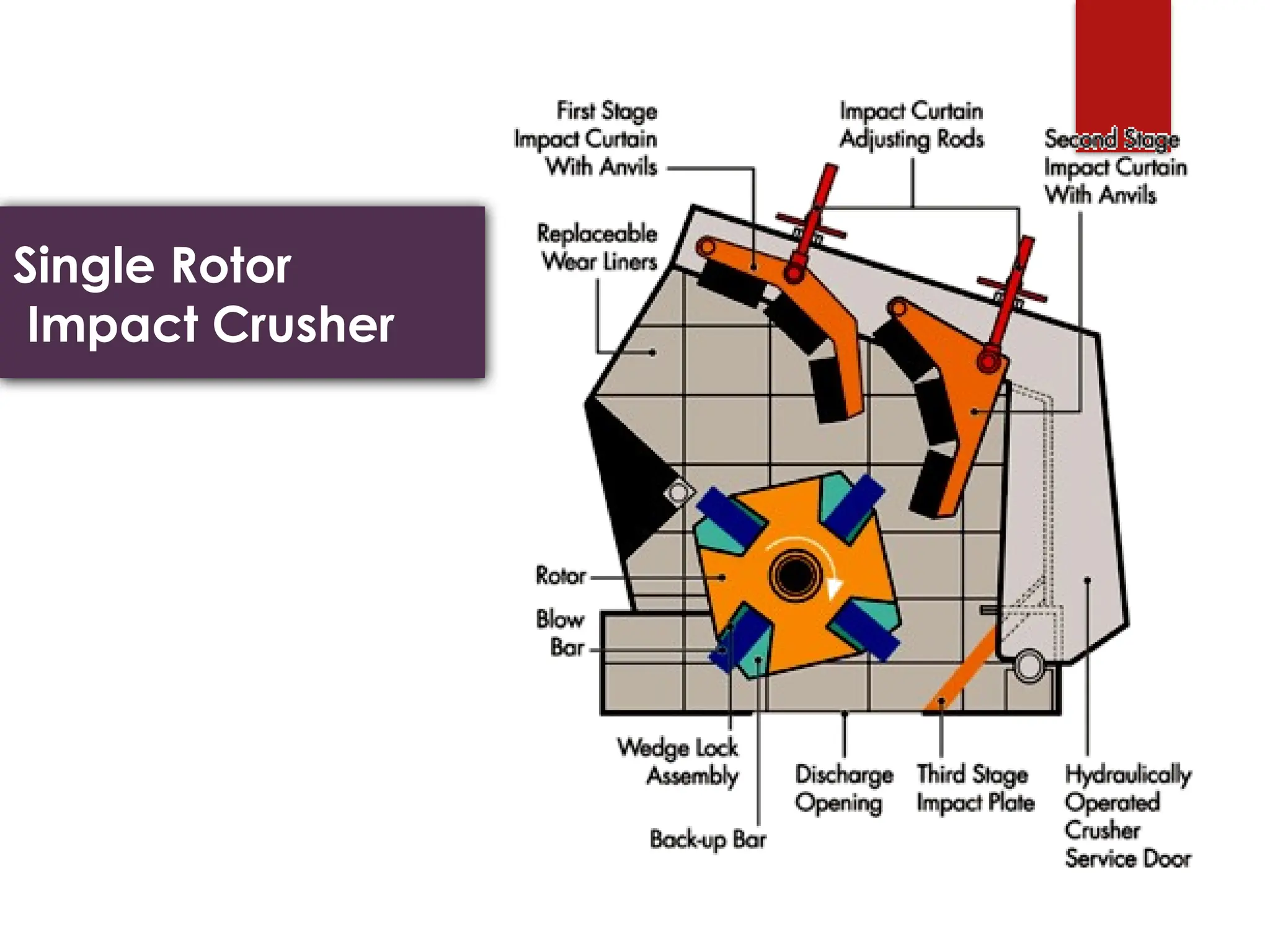

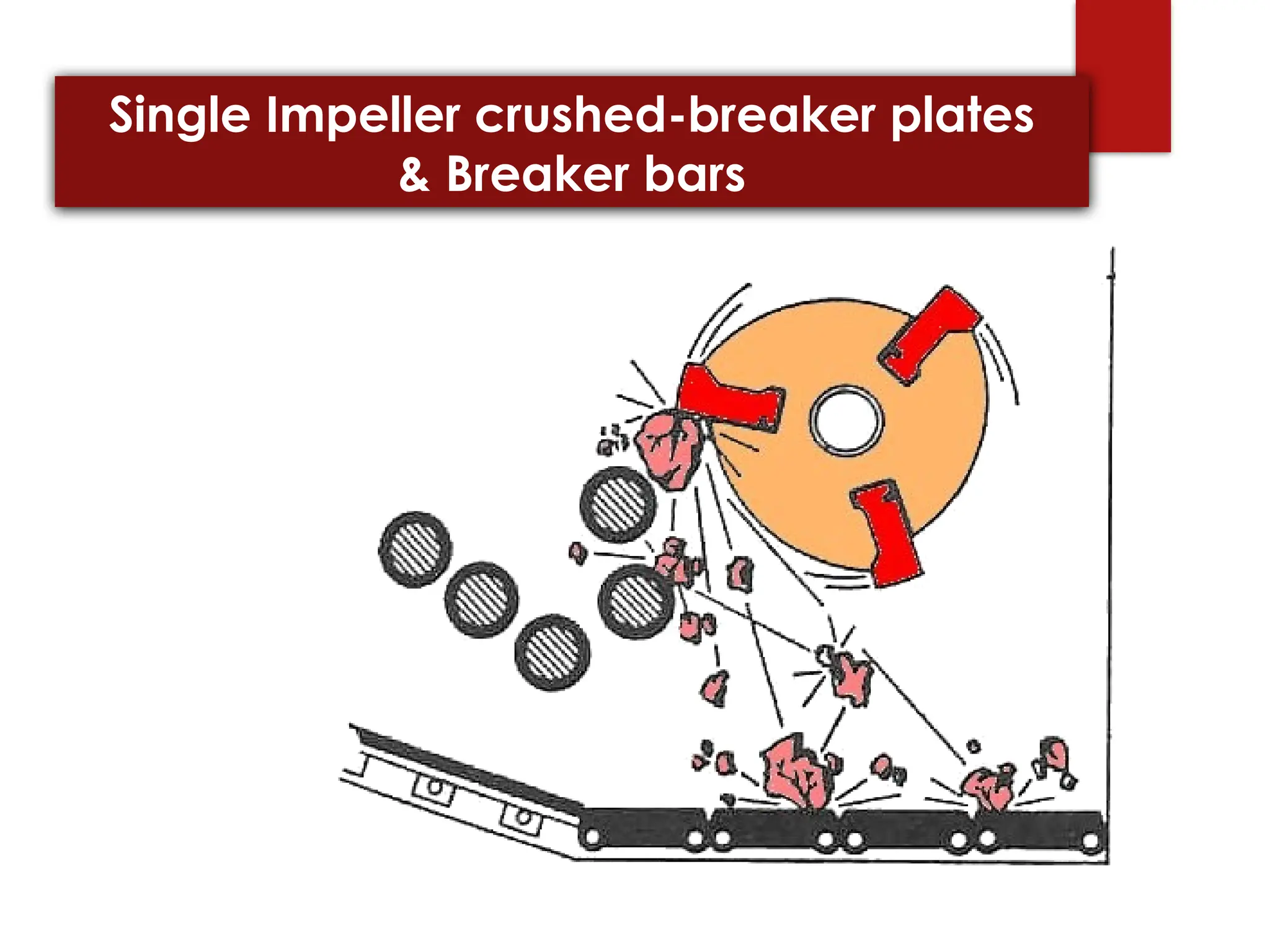

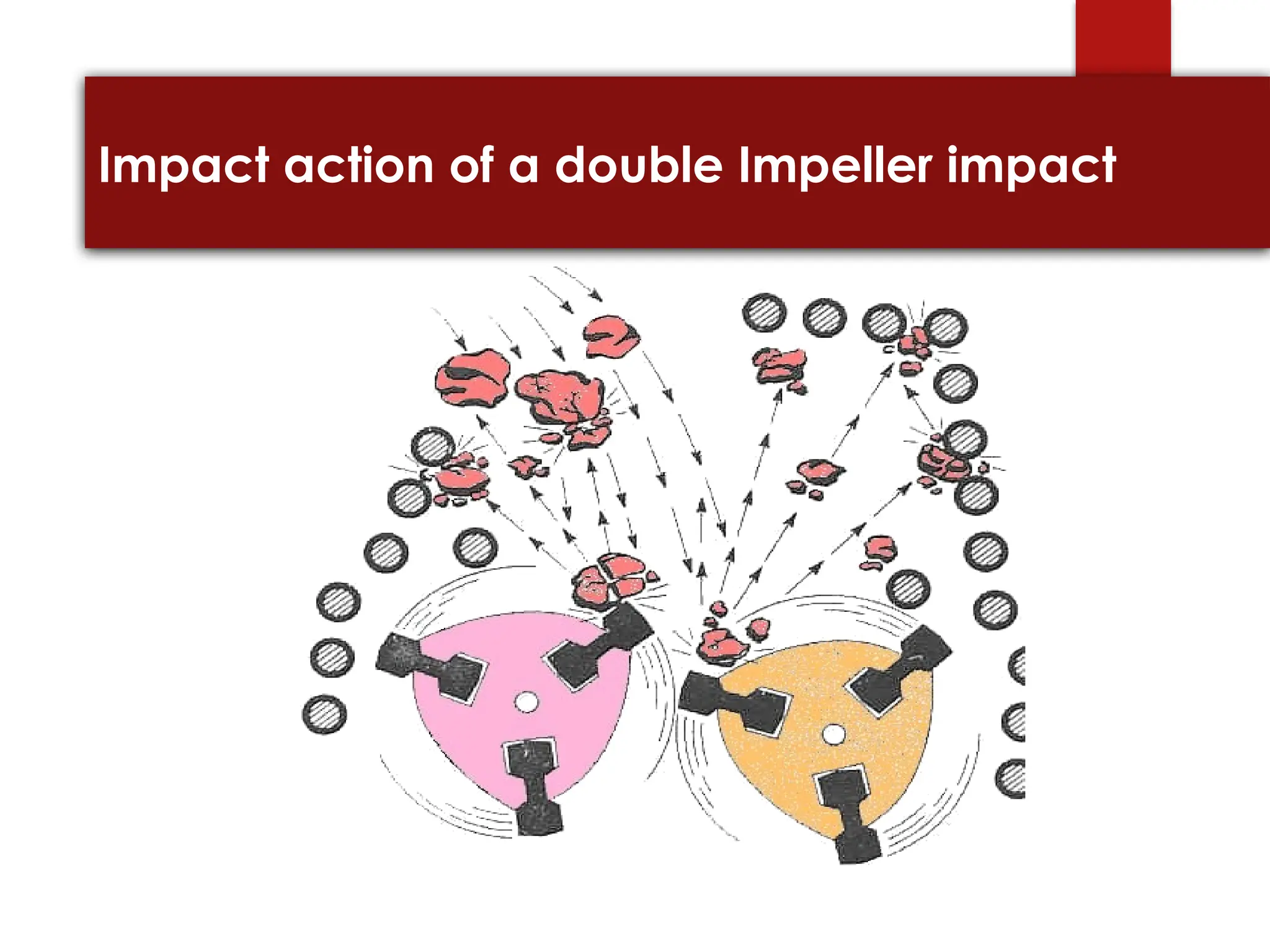

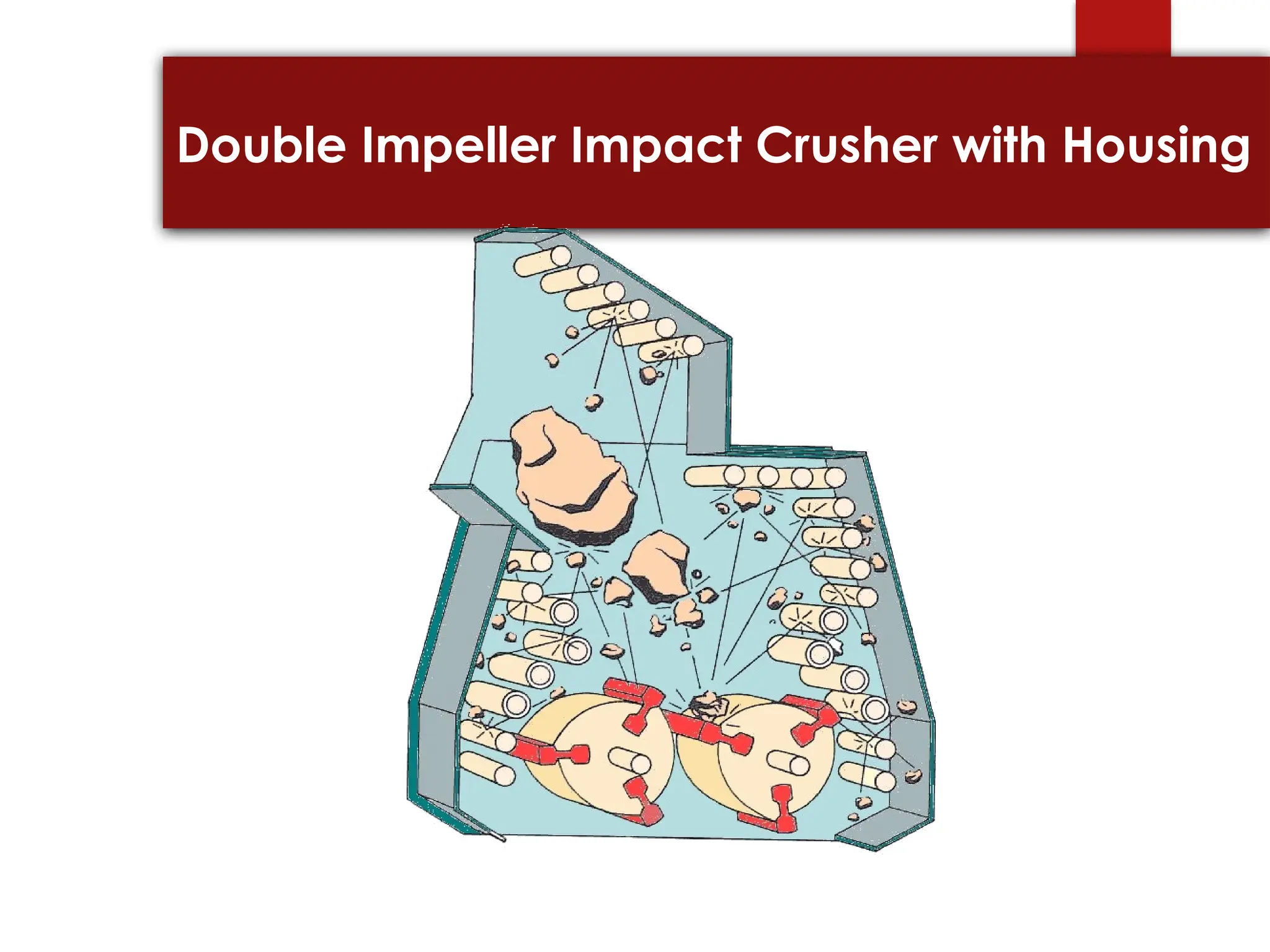

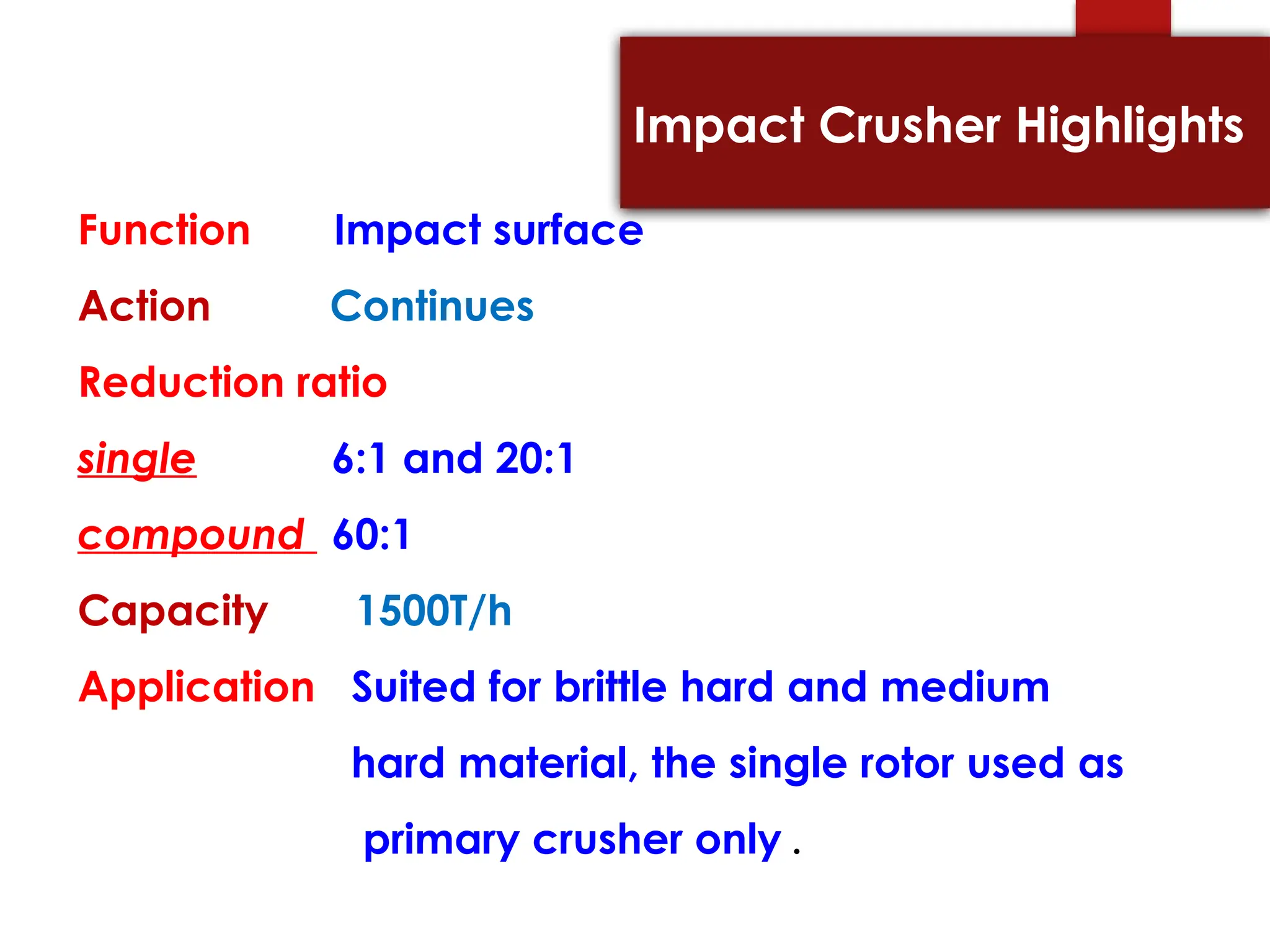

The document explains various mechanical reduction methods in crushing, highlighting impact, compression, shear, and attrition as primary mechanisms. It details different types of crushers, such as jaw crushers, gyratory crushers, and hammer crushers, along with their applications and operational mechanics. The comparative analysis includes capacity, reduction ratios, and suitability for different materials, portraying the complexity of the crushing process.